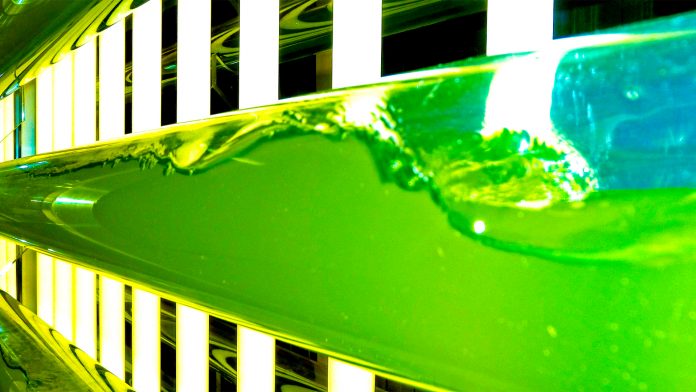

LGem’s proprietary GemTube tubular photobioreactors help to cut the costs of algae production in aquaculture.

Algae are not new in the aquaculture sector. In fact, algae are in many cases indispensable for the success of the aquaculture industry. The biggest hurdles for in house algae production in the aquaculture industry are the high costs, the labour intensiveness, and the complexity of maintaining healthy algae cultures. Traditionally, hatcheries have used big plastic bag type systems and bubble columns. The use of these systems has shown to be very expensive and not very efficient in terms of microalgae production; so the costs of algae production can therefore reach up to one third of the total hatchery costs.

LGem offers proprietary tubular photobioreactor systems which bring down the production costs and simplify the production of algae in aquaculture. LGem has been an active player in the market for microalgae production systems for many years. Back in 2006, LGem started with a novel algae production technology, the Green Solar Collector. Although it looked very promising in the beginning, we soon found out that it was far too expensive to be used in commercial applications.

Since then LGem has developed and examined all sorts of algae growing systems. Starting from plastic bags to bubble columns to polyethylene thin film sleeves on the ground to PVC tubes in both helical and horizontal orientations. Finally, we are convinced that glass tubular helix systems are by far the best solution. Not only do glass tubular systems offer extreme durability and scale up opportunities, they are also the cheapest option when evaluating the cost price of algae production.

Wavy wind and Bubble brush technology

Each generation of photobioreactors was tested in house in our own commercial algae farm. LGem demanded for its own operation that the system be practical, easy to use, reliable, affordable and hygienic. This gave us the unique opportunity to design, engineer and test on-scale systems which tick all these boxes.

When analysing conventional algae production systems, one of the first things that LGem realised was that a fundamental change had to be made in the way photobioreactors were operated. Conventional tubular systems use a lot of power for circulation and aeration to prevent biofouling and oxygen buildup. Also, huge amounts of valuable CO2 are lost when oxygen is scrubbed out.

As a solution for this, LGem introduced its patented ‘Wavy wind and Bubble brush’ technology. Air moving through the glass tubes creates waves that ensure the removal of O2 and the supply of CO2 evenly over the whole tubular helix at a very low energy input (100-200 watts per 1000 litres of culture): around a tenth of the energy input of conventional tubular systems. Since the entire system can be propelled by the moving air only, no centrifugal pumps are needed. Therefore, even fragile microalgae species that are often used in aquaculture, such as Rhodomonas and Isochrysis, perform very well in LGem’s GemTube systems.

GemTube systems

Recent research conducted by Pieter Oostlander from Wageningen University, as part of the RAAQUA (Robust Algae cultivation in AQUAculture) project, showed that there are huge differences in production costs per kilogramme of algal biomass depending on the systems used and whether additional artificial light was used. In the presentation of his paper ‘Making money with algae in aquaculture’, Oostlander compared several production systems side by side to see which system yielded the lowest production costs.

The conclusion was that LGem’s GemTube tubular photobioreactors systems) have significant lower productions cost than traditional bag or bubble column systems. In the base case scenario, the cost price for biomass produced with GemTube systems was one third of that in bag or bubble column systems. The cost price in GemTube systems could be reduced further to about a tenth of the cost price in the base case scenario by increasing light levels and by maintaining growth parameters at optimal values.

LGem offers its GemTube tubular photobioreactors with volumes ranging from 25 to 18,000 litres. For more information, please contact us at info@lgem.nl or visit our website at www.lgem.nl.

Sander Hazewinkel

LGEM BV

+31618808440