Linda Grieder of RethinkResource explains how the company’s Circado platform, which allows the convenient exchange of production side streams, could help producers deliver on circular economy ambitions

The current state of knowledge is unambiguous: our way of life and our growing economy already require a second planet’s worth of resources, something we don’t have. While we take excellent care of our bank accounts, we consume our ecological capital and diminish its returns. Over the next 80 years, more of us will want a big house, a car to drive to work and a steak for lunch. And the pressure will increase.

The only way out is to make real progress. Business as usual – or even a little better, a little more efficient – will not be enough. We need to dedicate our efforts to areas where we can achieve the most impact. We need to promote and connect existing topics and activities that create real sustainability. For the consumer, this means consciously consuming sustainable products. For the producer, this means decoupling economic growth from resource consumption.

In short, the future is manufactured in the form of sustainable products. Sustainable and resource-efficient production and consumption has to become the standard mode of operating. The realisation that progress does not happen despite, but because of, sustainable innovation needs to move into the focus of public perception and entrepreneurial minds.

What is the role of manufacturing?

Every year, the EU landfills or burns around 925 million tons of material (not including construction, mining and quarrying wastes). More than a quarter of this comes from manufacturing. The European Commission estimates that around 600 million tons of material incinerated or landfilled could be recycled or reused.

However, there is even bigger potential in the production, processing and transportation of the raw materials that go to waste.1 This is the essence of the sustainability problem of all producing industries. It is as much a challenge as it is an opportunity. Manufacturing a product from side streams of another factory, instead of using raw materials that are mined specifically for the task, lets both partners profit from the co-operation. Both final products are not only more sustainable, but also reduce the costs and impacts of raw material sourcing and side stream disposal.

The future is circular

The ideal state of an economy of such production systems is known as the circular economy. Circularity means bringing side and waste streams back into factories wherever possible – a closed loop, keeping materials in the system as long as possible and utilising them at the highest possible value.

Getting there doesn’t require a revolution. Rather, it is an evolutionary process, taking many small steps – single innovations – based on existing trends. Application by application, we are moving away from the current system of separate value chains to a connected system of cross-industry value networks, utilising synergies and closing the loop. Already, the most progressive innovators create new sustainable products by using – upcycling – production side streams. In doing so, they lay the foundation for future resource-efficient production systems.

Why isn’t everyone doing this?

Although the demand for these innovations is high, almost all of them are still niche products, manufactured in low quantities by small or medium-sized enterprises. The way into the mainstream is complicated by the inherent properties of side streams that made them side streams in the first place: variations in volume and properties, and the lack of standardisation. Most productions are run in a way that allows them smooth, continuous output of the main product, ideally without variation, to meet the demand for constant input of other producers, or to be sold as commodities on the markets.

In contrast to standardised commodities, side streams often absorb the inevitable variations that occur before or during processing. This often prevents them from being sold as standardised commodities and makes disposal the most convenient solution. Small businesses that produce niche products are flexible enough to compensate for the variations in their sourcing. A multiplication on a larger scale requires new sourcing processes that allow the integration of a higher variety of streams, suppliers and materials in an agile way.

Transparent supply chains and digital sourcing

The current transformation of production systems through digitalisation and the Internet of Things removes the old barriers from the exchange of materials. As an ever-increasing amount of data is collected from production and associated with the products that leave a factory, the need for standardisation of commodities decreases. Automation systems gradually become smart and gain the ability to dynamically adapt processing parameters to specific product properties. Additionally, the digitalisation of transportation and logistics allows for easy, automated co-ordination of complex supply networks.

These developments will gradually diversify the current state of materials as standardised commodities into more and more different, non-standardised commodities that are a lot like the side streams from which they originate. Ultimately, this will pave the way to the mainstream for upcycling innovations. An essential step in this transformation is the exchange of the side streams, along with the relevant data.

RethinkResource and the platform Circado

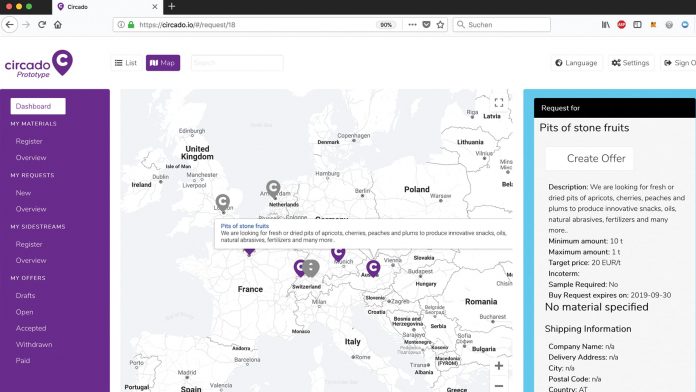

We at RethinkResource believe that the circular economy will be the key development for sustainable production systems. This is why we dedicate our time and efforts to creating the tools and applications that are necessary to close the loop. One of these tools is Circado, the first cross-industrial trading platform for industrial side streams in Europe.

Circado is an open, transparent and simple trading platform, specifically built to allow the convenient exchange of production side streams directly between producers. Circado is currently under development in an open prototype stage. We plan to launch the first beta version by next year. Our open prototype is accessible for every company and ready to scale! Join our journey towards a circular economy on circado.

Reference

1 It is estimated that resource efficiency improvements all along the value chain could reduce material inputs needs by 17%-24% by 2030, and a better use of resources could represent an overall savings potential of €630bn per year for European industry. Business-driven studies demonstrate opportunities for the European industry from circular economy approaches to boost EU GDP by up to 3.9%, by creating new markets and new products. From the European Commission’s Communication to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, ‘Towards a circular economy: A zero waste programme for Europe’.

Definitions

- Circular economy: the circular economy keeps production materials at their highest possible value, beyond the lifecycle of single products. Materials are returned to production wherever possible. The ability to re-use or process production side streams to turn them into resources is a vital factor. The opposite of the circular economy is the linear economy, where most of the materials are landfilled or burned after the end of a product’s life cycle.

- Upcycling: re-using former waste, or otherwise unused material, to create a product of higher value than one made without upcycling.

- Side stream: a waste, by-product or co-product rejects from a production process. This includes any kind of material that is continuously lost from a production process. Many industrial side streams today are waste streams because no better application has been found than landfilling or burning them.

- Side stream valorisation: instead of costly disposal, many valuable components in a side stream can find applications that return a profit. Side stream valorisation allows companies to easily recover valuable material properties like nutrients, creating a direct positive impact on the sustainability of their business and their value chain.

- RethinkResource: RethinkResource (www.rethink-resource.com) is a young and growing company promoting the circular economy and working with producers to improve the resource efficiency of their products. It mostly focuses on the most ecological and economical use cases for industrial side streams. Besides its project-based consulting services, RethinkResource also develops its digital trading platform for industrial side streams (www.circado.io).

Linda Grieder

RethinkResource GmbH

Technoparkstrasse 1

CH-8005 Zürich

+41 79 726 35 00

linda@rethink-resource.com