Dr. Carlos Ziebert, head of the Calorimeter Center at the Institute of Applied Materials – Applied Materials Physics, outlines how heat flux sensors can help in advancing thermal management of cells.

Established in 2011, the Calorimeter Center at the Karlsruhe Institute of Technology’s (KIT) Institute for Applied Materials – Applied Materials Physics now operates Europe’s largest battery calorimeter laboratory. It provides six Accelerating Rate Calorimeters (ARCs) of different sizes, from coin to large pouch or prismatic automotive format, which allows the evaluation of thermodynamic, thermal and safety data for lithium-ion (Li-ion) and post-lithium batteries on material, cell and pack level for both normal and abuse conditions (thermal, electrical, mechanical). However not all types of measurements need such a sophisticated calorimeter. Small heat flux sensors (HFS) are already able to collect data that are needed to advance the thermal management.

Possible measurements with heat flux sensors

With increasing energy density, the thermal management of Li-ion batteries is becoming more and more important, because an uncontrollable increase in temperature of the entire system (so-called thermal runaway) can cause an ignition or even explosion of the battery with simultaneous release of toxic gases. In order to adapt the thermal management system to the individual needs of the cells, quantitative data of the cell thermal parameters are needed. You need to know how many watts a cell will generate and dissipate under certain conditions. It will be shown how heat flux sensors can be used to provide:

- values for the specific heat capacity;

- heat transfer coefficients; and

- values for the generated heat.

Working principle of an HFS

A thermopile-based heat flux sensor is composed of tiny, serially connected semiconductor piles sandwiched between two flat surfaces, forming the sensor. Any heat flux passing through the sensor creates a temperature difference. Its operation is based on the Seebeck effect, according to which a temperature difference between two dissimilar electrical conductors or semiconductors produces a voltage difference which is proportional to the heat passing through the surface. This voltage difference on different areas of a Lithium-ion cell is read out using a data logger, which is attached to a terminal board connecting the wires coming from the sensors. Depending on the sensor’s sensitivity the results are converted into the heat flux. Common packaging materials, in which the thermopiles are embedded, are polyamide, kapton, anodised aluminium and silicone. An HFS is able to detect all three possible types of heat transfer: convection, conduction and radiation.

Measurement of effective specific heat capacity

In order to measure the effective specific heat capacity Cp of a Lithium-ion cell, an HFS is attached on its surface and the heat flux response on a series of temperature steps is recorded. By integrating the peak areas and dividing by the cell mass, the effective specific heat capacity as a function of temperature can be calculated.

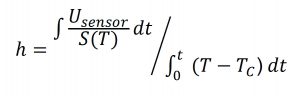

Determination of heat transfer coefficient

Another important parameter that can be measured using HFS is the heat transfer coefficient h. It is given as the quotient between the area of the sensor signal during the cycling of a cell and the area of a thermocouple signal at the same place:

with S(T): sensor sensitivity.

The h value determined by the classical dummy method (M1) differs a lot from the h value determined by HFS (M2). In the dummy method a dummy made from an Al alloy with similar mass and dimensions as the cell is heated up stepwise by the heaters in a calorimeter chamber. h is determined from the slope of the curve of the temperature difference between the dummy and its surroundings versus the time. This situation differs from a lithium-ion cell where the heat is generated inside. In addition, the HFS method allows to determine the heat transfer coefficient simultaneously as a function of temperature and applied charge/discharge current.

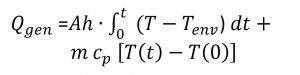

Determination of generated heat

After the Cp and the h value of a lithium-ion cell are determined by using heat flux sensors, the temperature data recorded by thermocouples attached to the cell surface can be converted to the generated heat in order to determine cooling requirements for the thermal management system:

with A: cell surface.

Thus, heat flux sensors are able to determine lots of parameters that are of utmost importance for the thermal management of cells. In addition, the HFS can be used in a similar way on the pack level by attaching them on different positions in the pack. We hope that the research in our Calorimeter Center will help the European battery industry to make further progress.

Dr Carlos Ziebert

Head of the Calorimeter Center

Karlsruhe Institute of Technology

Institute of Applied Materials – Applied Materials Physics