ChemX Materials Ltd on supplying high purity materials to the energy transition and the decarbonisation markets.

ChemX Materials Ltd (ASX:CMX) currently has three projects that are under development regarding high purity materials and decarbonisation efforts:

- The HiPurA® High Purity Alumina (HPA) processing technology. This proven innovative technology produces >99.99% (4N) HPA for lithium batteries and synthetic sapphire markets. ChemX’s strategy is to have production facilities located globally to reduce the risk of supply disruptions and lower the carbon footprint of the logistics chain;

- The Jamieson Tank Manganese project located on the Eyre Peninsula in South Australia, a Tier One mining and exploration jurisdiction. The focus of this project is the development of lithium battery manganese cathode precursor-grade products. ChemX has completed its maiden drill programme over the project, and metallurgical test work is underway to produce lithium battery cathode-grade high purity manganese sulphate monohydrate (HPMSM); and

- The Kimba Kaolin/Halloysite project, which is also located on the Eyre Peninsula in South Australia. ChemX is investigating CO2 capture and pharmaceuticals and focusing on the traditional kaolin markets, the use of kaolin in the decarbonisation of industrial processes, and the use of halloysite in hydrogen/oxygen storage.

In addition to the targeted minerals, ChemX is exploring the Eyre Peninsula tenements. There have been previous discoveries of ionic adsorbed rare earth elements (REEs) in the same geology around their tenement, including the boundary. Samples are currently being assessed from the recent drilling programme for REEs; however, as the previous exploration was not assayed for REEs, ChemX is required to wait for the assay results to confirm their presence on their tenements.

The HiPurA® HPA technology is the main focus for development in the short term. The process has significant advantages over current or proposed production technologies:

- Scalability enables production to be expanded relatively simply and quickly as demand increases;

- Being modular allows for the development of production facilities close to battery production facilities, which reduces the length and carbon footprint of the logistics chain;

- As the process does not use aluminium metal as a feedstock and is significantly lower in energy consumption, the carbon footprint of the production is lower than existing processes;

- It is not tied to any mining operation, avoiding the timeframe and cost of establishing a mining operation; and

- There is excellent potential to produce >99.999% (5N), or higher purity, HPA.

What is HiPurA® technology?

The HiPurA® technology provides the opportunity to develop HPA with different properties and characteristics, potentially varying particle size, shape, surface area, and porosity. In addition to HPA, the process can produce battery cathode precursor-grade aluminium salts and boehmite.

Additionally, ChemX is bringing the HiPurA® technology to life with a two-stage development process to mitigate any scale-up risk. The commissioning of a micro-plant capable of producing up to 5kg per day is currently underway, which will be a continuous process utilising the technology that will allow for optimisations to be applied to the next stage.

The second step is a pre-feasibility study into a larger pilot plant, which is undergoing a pre-feasibility study– ChemX expects this to be completed by the end of Q2 2022.

Subject to a successful outcome from the study, it is anticipated that construction will commence in Q3 2022. ChemX expects construction times for commercial-scale plants to be reduced to less than 12 months.

As well as establishing the operational parameters of the process, ChemX intends to collaborate with end-users to develop products with the optimum high purity materials and morphological specifications required for their process. The flexibility of the HiPurA® process enables the production of different products, morphologies, and purities within a single plant by changing the operating conditions.

Uses of high purity alumina

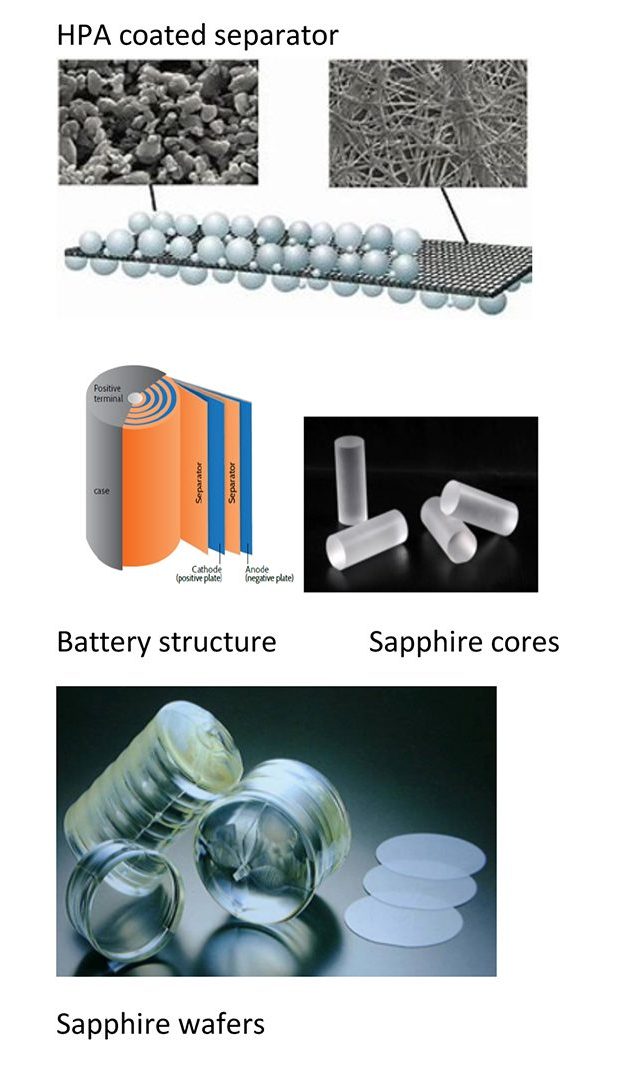

There are two significant consumers of high purity alumina: lithium-ion batteries and synthetic sapphire. The requirement for each use is different, as batteries require a purity of 99.99% (4N, <100g of impurities per tonne of product) and a limited range of shapes and sizes, whilst sapphire manufacturers require solid pucks of 99.999% (5N) purity (<10g of impurities per tonne). Thus, the next generation of batteries and sapphire will possibly require even higher purities of 99.999% and 99.9999% (6N), respectively.

In batteries, the HPA is utilised to coat the separator between the anode and cathode to improve its thermal capacity, thereby reducing the risk of thermal runaway and the well-publicised, rare fires in mobile phones and electric vehicles. There is also research into using HPA to coat the anode and/or cathode to provide stability to the battery, reduce the use of cobalt in the battery chemistry, and decrease the losses of capacity commonly encountered in the initial charge-discharge cycle.

The main markets for synthetic sapphire are LED and semiconductor substrates. The unique properties of sapphire make it ideal for scratchproof windows and lenses on high-end electronic devices and optical components.

The benefits of the HiPurA® process

The provisionally patented HiPurA® process significantly improves the processes outlined in the following section. The feedstock does not require to be either highly purified or mined and is available in bulk quantities in almost every country.

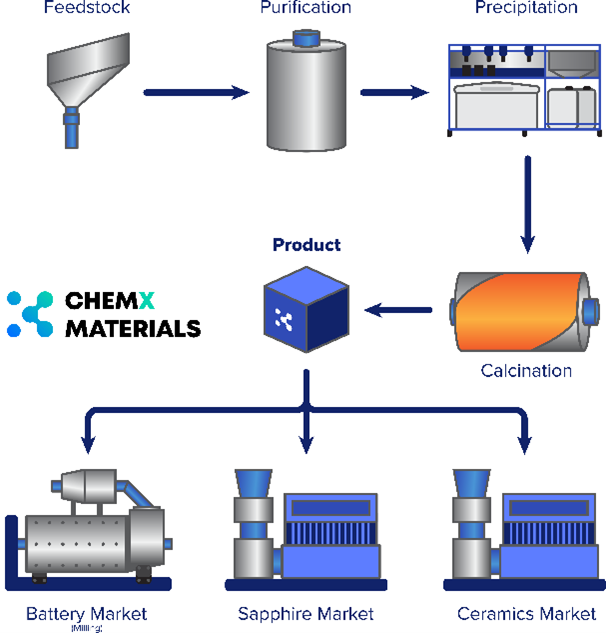

The feedstock is leached, filtered to remove insoluble impurities (typically <0.1%), and fed into the purification process. The only solid waste from the process is generated at this stage and is expected to be <5kg per tonne of HPA produced. The purified product can be utilised to create two high purity material products: high purity aluminium salts or high purity alumina.

- The high purity aluminium salts are used as precursors to NCA (nickel-cobalt-aluminium) cathodes for lithium-ion batteries; and

- The high purity alumina can be used as the separator in batteries or sapphire production.

The current process produces a high 99.99% (4N) pure product, which is expected to be further purified by simply repeating the purification process to improve the purity to 5N and potentially 6N material.

One of the main by-products of the HiPurA® process is a highly desirable chemical product used in several industries, including agriculture and chemical manufacturing, further reducing ‘waste’.

The HiPurA® process operates all stages, other than the drying and final calcination to alpha phase alumina, at ambient temperatures. The reagents used are globally available and are relatively low in cost. Solid waste is minimal, while liquid waste can be used to input into other chemical processes.

Additionally, the minimal solid waste and circularity of the key inputs and waste materials make the process environmentally sustainable. Utilising renewable electricity also significantly reduces the carbon cost of production, making the final HPA or aluminium salts a lower carbon alternative.

Strategy to produce high purity materials

The potential to produce alternative products, such as high purity aluminium salts and high purity alumina, is a significant advantage over the other processes, which can only produce HPA. Thus, the ability to produce 5N and 6N products is also a major advantage over the US Bureau of Mines (USBM) process outlined below. No special construction materials are required as the process does not use highly corrosive chemicals or produce corrosive gas streams.

Further work is underway to investigate the use of alternative feedstocks in the process. These alternatives include aluminous wastes from other industrial processes to reduce the overall environmental impact and add more circularity the process.

ChemX’s strategy is to optimise the process through the micro-plant and pilot plant and then develop production facilities within our customers’ supply chains. The benefits of having several production facilities located within the battery supply chain locations are:

- Significantly reduces the risk of supply disruptions caused by relying on long logistics chains;

- Reduces the reliance on a single production facility;

- Significantly reduces the carbon cost of supply, both from a shorter logistics chain and the low carbon footprint of the HiPurA® technology; and

- It meets the desire to have the complete battery supply chain within a jurisdiction.

Current production methods of high purity alumina

Currently, the main route for producing high purity alumina is using the alkoxide process. The alternative technology that has been proposed is the USBM alumina process. The former process utilises high purity aluminium as the starting material, reacts it with an alcohol, and then reacts the alkoxide with water to produce the alumina. The feedstock is expensive as the aluminium metal is refined to a higher purity than typical aluminium metal and also carries with it the significant carbon and environmental footprint associated with the Bayer and smelter processes. This method can produce all purities of HPA up to 6N; however, it cannot produce aluminium salts.

The USBM process, which has been known since the 1940s, utilises a much lower cost feedstock in the form of clay or other low-value aluminous minerals. Several proponents of this technology use kaolin as a feedstock to the USBM process to produce HPA. The process is based on the change in solubility of aluminium chloride in hydrochloric acid; as the acid concentration increases, the solubility decreases. The kaolin is mined, beneficiated, and leached in hydrochloric acid at 80-105°C.

After filtration, the leach solution has hydrogen chloride gas injected to increase the acid concentration and precipitate aluminium chloride. The leach residue is neutralised and disposed of. The slurry is then filtered, and the aluminium chloride is re-dissolved in clean water. The filtrate is treated to regenerate the HCl gas for use within the process.

This cycle of precipitation and redissolution repeats until the impurities have been removed; generally, at least three cycles are required for 4N purity. The final aluminium chloride product is filtered and calcined, typically in two stages.

The first stage operates at 800°C and separates the chloride from the aluminium producing a gas stream composed of HCl and steam, and an aluminium oxide. The gas stream is treated to recover the HCl, which is recycled within the process. The aluminium oxide is then heated to 1200°C to change it to the alpha crystallographic form that battery manufacturers require. It is believed that the USBM process will struggle to make the higher purity products due to a significant increase in the number of purification cycles needed.

The cost of the USBM process is primarily centred around the recycling of the gaseous hydrogen chloride. The plant must be sufficiently large to benefit from the economy of scale within the very energy-intensive HCl regeneration process to achieve economic success. This, combined with the necessity to construct the plant using expensive chemically resistant materials, result in a high CAPEX. At this time, the USBM process is not in commercial production.

The future of high purity aluminium

ChemX Materials aims to be one of the most responsive manufacturers of high purity aluminium products and will be engaging with the technical leaders to translate new ideas into a commercial reality. There is a clear trend toward higher purity materials being used in both batteries and sapphire. Thus, the capability to produce 5N and 6N will become increasingly important.

Other advances include coating the cathode and/or anode material with nanoparticles of HPA to improve battery performance by notably reducing the drop in capacity after the initial discharge. The size, morphology, and porosity of the HPA in batteries is also an area with significant developments.

The HiPurA® team is already developing methods to produce novel materials at a small scale (2-5kg/day) utilising a dedicated micro-plant, allowing the more innovative consumers access to relatively large volumes of developmental materials to trial before large scale adoption. The flexibility of the HiPurA® Process means that existing plants may be modified to produce novel materials.

Optimising the high purity alumina process for end-users

ChemX is focused on developing materials for new and developing technologies for use in the energy transition and decarbonisation processes.

The HiPurA® technology has been developed to produce HPA in a scalable process that can expand production as demand requires. The additional benefits of being capable of producing battery cathode precursor aluminium salts and boehmite provide a wide range of materials for the lithium battery supply chain. The product’s flexibility also allows access to other markets presently limited by the purity and/or morphology.

The modularity of the process allows production to be co-located with the end-user facilities; combining this with the use of locally sourced feedstocks and reagents will significantly reduce the length of the logistics chain, reduce the potential of supply disruptions, and reduce carbon footprint. This also allows for the specific product specifications for the co-located facilities to be optimised to the end-user, ensuring greater quality continuity.

ChemX will have its micro-plant operational in Q2 2022, producing up to 5kg per day. The larger pilot plant will be developed within 12 to 18 months. ChemX is currently working with HPA, aluminium cathode precursor salts, and boehmite buyers to create products with the unique specifications required for their process.