HIPERION solar panel technology can unlock the potential of a rooftop with concentration photovoltaics and micro-tracking, offering solar panels that are 40% more efficient.

As the world moves towards renewable energy sources, the replacement of thermal vehicles and fossil-based heating systems will put significant pressure on energy production. This requires higher energy density in densely populated areas, such as for autonomous zero-energy buildings or solar car ports. The EU-funded project HIPERION (GA n° 857775) – that brings together 15 partners from ten European countries, including research centres, industrial companies, solar installers and one photovoltaics (PV) manufacturer – offers a promising solution to this challenge. By combining concentration photovoltaics and micro-tracking on ultra-high efficiency space-grade solar cells, HIPERION solar panel technology can boost energy production up to 40% compared to existing PV solutions.

Presentation of HIPERION solar panel technology

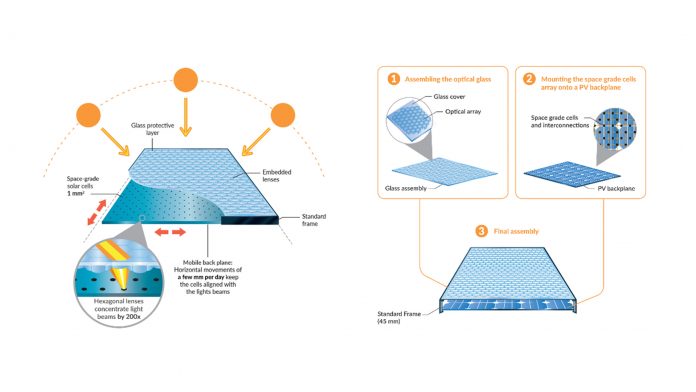

HIPERION technology utilises integrated optics to concentrate sunlight onto small areas of space-grade solar cells, with a concentration factor of 200x, resulting in more efficient energy conversion. The high concentration factor allows for a reduction in active area by a factor of 200, making the use of expensive multi-junction (MJ) solar cells affordable for terrestrial applications. With a built-in micro-tracking system, the hybrid panels can operate at a wide range of angles (+/- 55°), enabling energy harvesting throughout the day. Fig. 1 (left) shows the principle of the micro-tracking.

Unlike other concentration-based solutions, HIPERION solar panel technology addresses the challenge of decreasing module efficiency during cloudy weather by adding a second layer of crystalline solar cells behind the transparent plane of MJ cells. This glass PCB serves as the front glass of a conventional panel. In this configuration, the wasted light is transmitted to these secondary cells to guarantee a continuous energy production. For this reason, this technology is referred to as hybrid as it combines concentration and conventional photovoltaics. Fig. 1 (right) shows the assembly of the hybrid HIPERION module architecture.

From concept to mass production

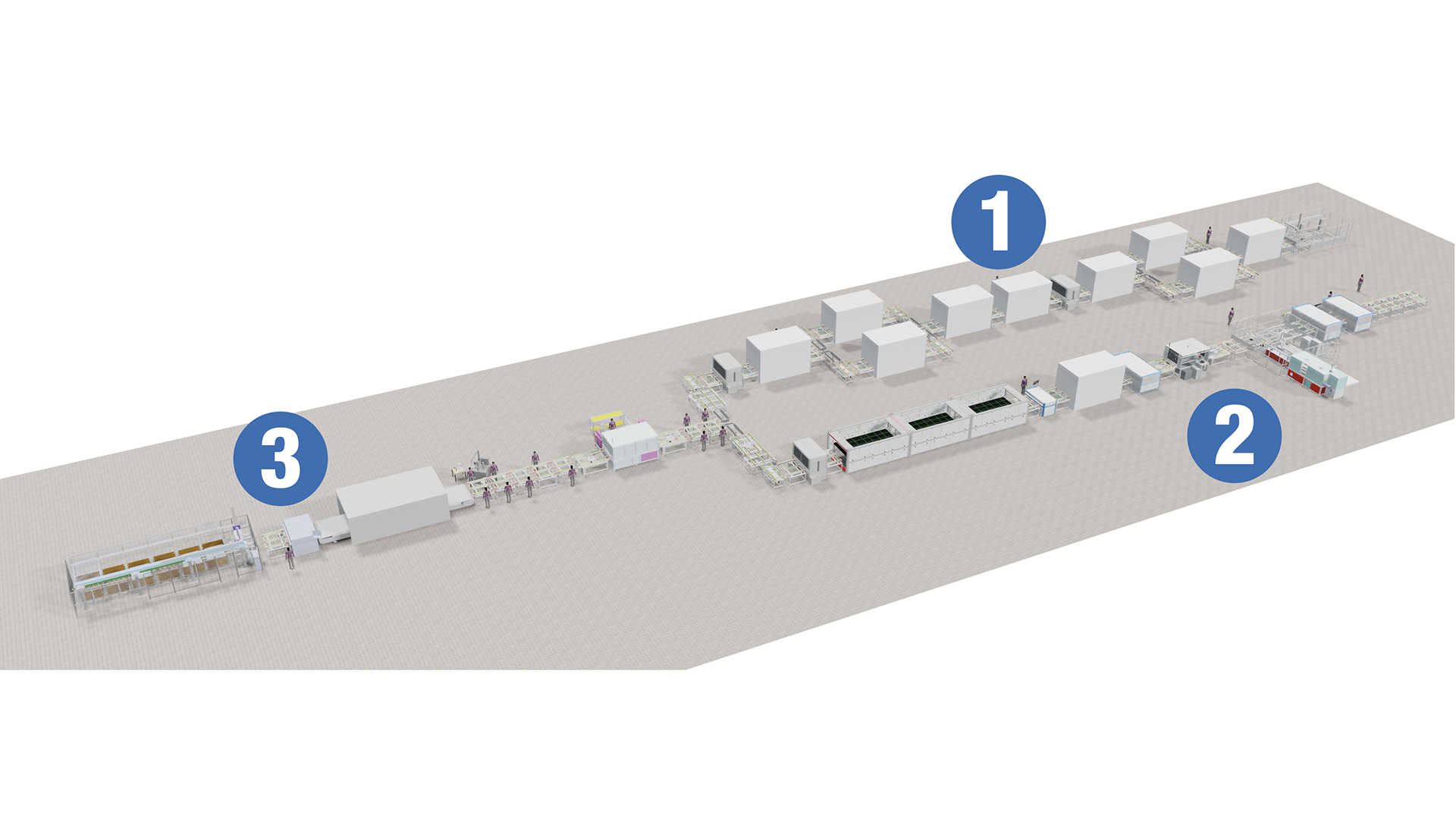

The HIPERION solar panel technology is built around a standard module architecture with a front glass that is replaced by a transparent circuit board. The board contains the MJ cells, which are pick-and-placed on the board known as the backplane. This assembly can be produced using a normal PV manufacturing line. The front plane, which includes the lens arrays, must be produced in parallel on a dedicated system specifically designed and validated for the project. Once both planes have been produced, they are mated together using guiding elements to ensure that the cells and lenses are at a controlled distance for all sun positions.

The main challenge in fabricating the modules is maintaining low tolerances between all mechanical elements to have a perfect alignment between lenses and MJ cells to utilise their full potential. Therefore, quality control of both planes is of paramount importance. A special machine was developed during the project to automatically control the position of each lens array and MJ cell before final assembly. If one module does not reach the specifications, it will be sorted out and repaired, if possible. The module fabrication process is completed with the framing and assembly of the linear actuators, which were also developed during the project to guarantee a 25-year operational lifetime.

Despite its apparent complexity, the HIPERION concept can be integrated into existing module production lines. The backplane assembly can be produced on a standard manufacturing line, while the front plane is produced in a parallel system, as shown in Fig. 2.

Power rating of hybrid modules

The power rating of hybrid modules, such as the HIPERION solar panel technology, presents a challenge as the module converts direct and diffuse light differently, and existing IEC standards do not provide guidelines for this purpose. The PV industry typically defines module price based on nominal power measured in standard test conditions (STC), corresponding to a module temperature of 25°C and an incident irradiance of 1,000 W/m2. However, the absence of a standard defining the amount of direct and diffuse light components in STC, coupled with the fact that no machines existed to measure the electrical performance of such hybrid modules, makes power rating more complex.

To address this challenge, the HIPERION project developed a special flasher that can generate perfectly collimated or controlled diffuse light, in a defined sequence. The flasher can also configure the module in perfect alignment between lenses and MJ cells and proceed to power assessment in direct light conditions, as well as switch to secondary cell power rating under diffuse light conditions. The module power is then defined as the sum of both contributions, with constraints on the direct and diffuse light conditions so that the sum corresponds to a global irradiance of 1000 W/m2.

The HIPERION project played a leading role in defining a metrology standard for the power rating of hybrid modules, beyond the scope of the project. This achievement is a significant step forward for the PV industry, providing a standardised method to measure the electrical performance of hybrid modules.

The potential of HIPERION solar panel technology

The HIPERION project aimed to demonstrate the industrial relevance of the hybrid concept at the pilot line level. Before the project began, the modules were only laboratory concepts. However, today hundreds of modules have been produced using custom industrial tools and shipped to pilot sites worldwide, including Germany, Spain, Portugal, Chile, and Switzerland, which feature various climatic conditions and weather constraints. The data collected from these sites will provide insights into where the hybrid concept will bring the most value. Specifically, the project aims to gain a better understanding of the technology’s potential in different locations and environments, which will inform future development and deployment strategies.

The solar power technology can help meet rising energy demands

HIPERION solar panel technology offers a significant improvement in energy production compared to traditional solar panels, with up to 40% more efficiency. This technology is particularly promising for meeting the increasing energy demands of densely populated areas, such as for autonomous zero-energy buildings or solar car ports. While the fabrication process requires careful quality control, it can be integrated into existing module production lines. The HIPERION solar panel technology has the potential to accelerate the transition to a more sustainable and resilient energy system. By collecting data from various pilot sites worldwide, we can obtain a better understanding of the technology’s reliability and energy gain in different environments, which will inform future development and deployment strategies. With further refinement and commercialisation, the HIPERION solar panel technology could play a significant role in shaping the future of renewable energy production.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N° 857775.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N° 857775.

Please note, this article will also appear in the fourteenth edition of our quarterly publication.