KSK Aqua develops innovative biological filters to ensure optimal water purification. Here they share how these clever solutions work.

In modern fish farms with recirculation, it is necessary to handle the waste substances in the water. Some of the waste products can be handled by filtering out solids, while the solute requires a biological filter.

In this article, we will focus on the biological filter and its function. In a biological filter, it is bacteria that convert the dissolved waste products into something else. In fish farms, it is preferably ammonium that must be converted. The first step is the conversion of ammonium to nitrite and from here on to nitrate. This allows a partial recycling of the water in the recirculating aquaculture system (RAS), as the fish can handle a certain amount of nitrate. In this process, the bacteria use oxygen, and this is called an aerobic process.

Aerobic filter (nitrification) is a filter where oxygen is available in an amount that ensures that all bacteria in the entire filter have sufficient oxygen. This filter is widely used to convert ammonium to nitrate. The water will be oxygenated before it passes through the filter and needs to be oxygenated when it comes out of the filter, before it is led into the fish tanks. These filters can be designed as moving bed bio filters (MBBR), where the filter elements will float in the water, or fixed bed bio filters (FBBR), where the filter elements do not move, and the water will flow through the filter elements.

At high recirculation degrees, it is often necessary to reduce the concentration of nitrate in the water. This is done by adding carbon and making sure there is no oxygen in the water. Bacteria thereby convert nitrate into free nitrogen and nitrous oxide.

Anaerobic filter (denitrification) is a filter where there is no oxygen available. This filter is utilised to remove nitrate from the water and convert it to free nitrogen and nitrous oxide. These filters are typically fixed bed bio filters (FBBR), as no oxygen can enter the filter for agitation. Typically, methanol is used as a carbon source for the anaerobic process.

For the filter to work optimally, it requires the dead bacteria that are on the surfaces of the elements and particles in the FBBR can be removed, otherwise the filter will clog, and the efficiency will decrease. There must also be fresh water for all surfaces in the filter, so that the bacteria get new ammonium/nitrite as well as oxygen or nitrate and carbon, depending on whether it is an aerobic or anaerobic process that is run in the biological filter.

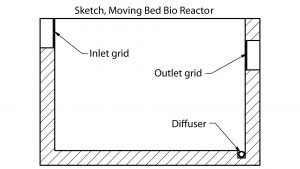

Moving bed bio reactor (MBBR)

In the moving bed filter, the elements float freely in the water and must have a density that is just below the density of water, as otherwise there is a risk that they will lie on the bottom and form anaerobic conditions, as they are not cleaned. Moving bed filters are considered self-cleaning as dead bacteria is flushed of the elements and out of the filter. Particles are also not trapped in the filter, which is made to convert ammonium and dissolved nutrients.

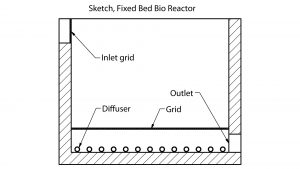

Fixed bed bio reactor (FBBR)

In the fixed bed filter, the elements have a density that is either greater than or less than the density of water. When the density is greater than the density of water, the elements will float to the bottom of the tank and the water will flow from the top through the elements and out at the bottom. The elements will be held in place by a grid or plate with holes so that the water can flow out to the bottom of the filter. When cleaning, the water flowing through the filter is stopped and air is supplied evenly over the entire surface of the filter. Hereby the elements are stirred, and the sludge is expelled out of the elements and then out with the rejected water. If the elements are lighter than water, it works the same way: the elements float up and are then held down by a grid that can be raised for cleaning. Fixed bed filters capture many of the particles in the water, which are filtered from the water. For this reason, this type of filter is often used after the moving bed filter as the last filter before the water is led back to the fish tank to remove the particles that a mechanical filter let through, and to remove the dead bacteria that is created by the biological filters.

There are also other mechanical properties that need to be focused on when building a biological filter:

- The filter element must be good quality so that they do not crumble over time – the filter should have a lifespan of up to 20 years;

- If the filter element is small, it will require a grate or grid with smaller holes to hold the filter elements inside the filter, leading to greater pressure loss across the grate or grid;

- The filter elements must have a design that prevents them from packing around the outlet grids. In the MBBR it is also important to ensure good agitation around the outlet grids so that the elements do not get trapped around the outlet, due to the water flow through the filter; and

- In MBBR, the surface inside the filter can advantageously be smoothed, so that the elements do not wear out so quickly due to abrasion.

Based on all these requirements for the elements, we have developed our Saddle-Chips, which is designed as an open element for easy cleaning and maintenance. The element is developed to optimise the flow of water around elements, as well as distribute the water optimally throughout the filter. Saddle Chips can be supplied in both recycled PP and virgin PEHD.

Please note, this article will also appear in the sixth edition of our quarterly publication.