The world is ready to embrace the green energy revolution. Elbert Loois, Chief Executive Officer at E-Tech Resources Inc., analyses the timely switch towards new energy materials and how the Eureka Project in Namibia can contribute towards a cleaner future.

Climate change is a very real and immediate concern. It affects all life on earth. The escalated global warming crisis has prompted global leaders like Joe Biden and the European Commission to set new carbon-cutting goals for 2030 and 2050 and aim for a cleaner future.

President Joe Biden aims for 50% of new US vehicles to be electric by 2030, while the EU Parliament is looking to cut greenhouse gas emissions by at least 55% by the same year, as laid out in the 2030 Climate Target Plan. The demand for electric vehicles (EVs) is growing, but the supply chain is under pressure.

What are rare earth elements, and why do they matter?

High-performance, permanent magnets propel 93% of EVs. These magnets are powered by specific rare earth elements (REEs), of which neodymium (Nd) is one of the most vital and widely used.

The most important use for neodymium (Nd) is in an alloy with iron (Fe) and boron (B) to make the strongest mass-produced permanent magnets (PMs). In fact, an average EV needs 1kg of NdPr oxide for every 2kg of REE magnet material.

The discovery for the application of NdPr in NdFeB permanent magnets in the 1980s also made it possible to miniaturise many everyday electronic devices. These include mobile phones, microphones, and loudspeakers. More recently, magnets have seen exponential growth through their use in large wind turbine generators.

The supply chain problem

While rare earth magnets are widely in demand, more than 80% of all refined rare earths products are currently produced in China, and more than 60% of the global REE ore mining and processing originates from China. Countries worldwide are actively seeking new rare earth resources amid trade disputes and political tensions.

A simple question of supply and demand for a cleaner future

Over the next five years, the REE metals market is expected to grow beyond the $20bn level. That is a growth of more than double the market value. More than 50% of the demand will come from producers of REE magnets.

With global EV sales expected to increase by a year-on-year average of 25% until 2030, approximately 25 million EVs will be sold by that year. Most of the demand will come from Europe and China.

Clean energy does not just begin and end with EVs, however. With Europe as its primary demand driver, and longing for a cleaner future, a total capacity of about 260GW of offshore wind power is expected to be established by 2030. Offshore wind power solutions are projected to grow at a year-on-year average of about 15% until 2030.

Accelerating market demand

The transition to cleaner future with sustainable technology is accelerating, creating a demand-supply gap for neodymium (Nd). Because of the accelerated demand for NdPr oxides, the current TREO (Total Rare Earth Oxide) production level will only satisfy the REE permanent magnet market for a very short time. The world will need to more than triple current NdPr production to feed the green energy revolution.

As demand increases faster than potential supply, a REE permanent magnet deficit is already expected in 2022.

E-Tech Resources Inc.

E-Tech Resources Inc. (TSX-V: REE, FSE: K2i) is a rare earth element development company that owns 100% of the Eureka Project. The Eureka Project in Namibia is located in one of Africa’s top mining jurisdictions and is strategically close to development infrastructure. Early metallurgical testing done to date indicates that the project has the potential to be one of the simplest REE projects to process globally.

E-Tech Resources’ company values are centred around sustainability and responsibility and the creation of a cleaner future. The company believes in a future of sustainably sourced and generated electric power. It is dedicated to helping to supply the key ingredients for the manufacture of electric motors that facilitate a sustainable energy future.

The Eureka Project summary

Simple mineralogy

The Eureka Project is characterised by simple mineralogy, with high-grade total rare earths oxide (TREO) predominately hosted in the mineral monazite. The coarse-grained monazite is hosted in numerous broad carbonatitic dyke swarms that intruded pre-existing rocks from a deep magma source, and today are exposed to the surface.

In more technical terms, the in-situ dyke grades range from 1-16% TREO, contributing to a current NI43-101 compliant Mineral Resource Estimate (MRE) at an average 4.8% TREO, as quoted in the SRK Consulting Technical Report, dated September 2021. The report also suggests immediate exploration potential to increase the resource by an additional 1.5 Mt.

Easy processability

Eureka’s inherent mineralogical characteristics make it amenable to low-cost beneficiation methods by off-the-shelf gravity separation equipment. Pure monazite concentrate could thus be beneficiated by low-cost physical methods alone, as shown in the SGS study.

Thus far, Eureka has yielded a 65%+ recovery of monazite to concentrate in the first pass, using a gravity process alone, with the concentrate level running at around 60% TREO, of which 16% is NdPr oxide. There are no hazardous chemicals or complicated beneficiation plants required. Further processing, or ‘cracking’, of low-Th monazite concentrates such as this are well established.

Simple operations and accessibility

Simple operations and logistics management are enhanced by an experienced board and management structure situated in-country with access to off-take partners. Namibia is a top tier country for mining and is one of Africa’s most stable countries.

Eureka has a flat topography with easy access to water and power and a 1.5-hour drive to the Walvis Bay container port – Namibia’s largest commercial port, which recently completed a $350m expansion in 2019. Mineral concentrates with low radioactive contents that meet international requirements are shipped safely from port.

The REE value chain

Generally speaking, REE supply chains have many levels of processing. In the first processing stages (ore beneficiation), the processing can be technically complicated, but this is not the case for the Eureka Project because of its relatively simple physical processability.

Compared to other raw materials, the REE supply chain is quite complicated. It is hard to give a transparent look into the metallurgically and geographically complex REE supply chains. This can also offer opportunities for early investors and traders.

NdPr market supply potential

Based on the current consumption for total rare earth oxides (TREO), current production from China, Lynas in Australia, and Mountain Pass in the USA could just about meet demand until 2030. However, doubling the current capacity of Lynas and Mountain Pass looks necessary to meet the accelerated high demand for the REEs of Nd and Pr. The demand for REE magnet material for permanent magnets (PM) in 2030 will make up about 35% of the total TREO demand.

A global supply deficit of 50,000t of NdFeB PM material is expected until 2030. This equals supply deficit of about 25,000t of NdPr oxide from new mining capacity.

Of today’s TREO demand proportions, NdPr consumption represents 25% of the whole basket. By 2030 this figure could increase to more than 35%, which implies the disposal of more traditionally used REEs, such as Ce, La and the mid-rare earths Sm, Eu and Gd.

Due to the high need for NdFeB PM for electrification and decarbonisation purposes, more than 50% of the whole TREO basket’s value will stem from NdPr compounds alone.

NdPr price 2020-2021

The increasing market demand for Nd and Pr, combined with the Chinese production quota and other geopolitical market measures, has led to a tightening of its supply.

The tightening, geopolitically influenced supply situation in the rare earths value chain led to a steeply increasing-price curve in 2020. This price increase continued in 2021 with an average 8% m-o-m increase in the first quarter alone.

The REE magnet materials Nd and Pr have experienced more than 150% price increase over the last two years.

REE Geology

REEs are not particularly ‘rare’ in the Earth’s crust. But economic accumulations of them are rare, and could be the key to a cleaner future.

Some are intruded into the Earth’s crust from depth and are regarded as ‘primary’, whilst others have been subject to chemical and physical weathering and can be described as ‘secondary’.

Mineral sands

Mineral sands contain reasonably large deposits but relatively low-grade REE. The REE minerals (monazite and xenotime) are by-products of larger Ti, Zr minerals (ilmenite and zircon) mining.

Mineral sand deposits are easy to mine as little blasting and milling are required. They contain high radioactivity because they are derived from thorium (Th) and uranium (U) bearing weathered granites and metamorphic rocks. An example deposit is at IREL Mineral Sands, India.

Carbonatites

Carbonatites contain reasonably large deposits with a higher grade of REE. Fresh ‘primary’ un-weathered carbonatites have a large grain size, whereas secondary weathered carbonatites have a fine grain size with variable radioactivity.

Carbonatites usually yield ‘light’ REE (aka LREEs) enriched, i.e., Ce, La, Nd, Pr deposits. Example deposits include:

• Primary carbonatite – Mountain Pass, USA; and

• Secondary carbonatite – Mount Weld, Australia.

Alkaline rocks

Alkaline rocks contain large deposits with a lower REE grade. These hard rocks require high energy equipment to blast and mill the stone. Alkaline rocks have complex mineralogy, yielding weird and wonderful minerals like eudialyte, which are challenging to process. These minerals generally exhibit mid-level radioactivity with higher amounts of ‘heavy’ rare earths (aka HREEs) Y, Dy, Tb. An example deposit is located at Lovozero, Russia.

Ion absorption

Ion absorption methods display small/shallow deposits with a low REE grade and low radioactivity. But they are easy to mine as they are hosted in soft clay. The REE is ‘leached’, i.e. chemical saturation in-situ. This leads to a higher environmental impact. An example deposit is the South China Clay Deposits.

Today’s REE production is centred on a handful of mostly carbonatite hosted deposits, mainly in China, proving China is the world’s dominant REE producer. Mineral concentrate production in USA and Myanmar also goes to China for further processing.

Only Mount Weld (Lynas) in Australia, Indian Mineral Sands, and Russia produce refined REEs outside China. Mount Weld uses its processing hub in Malaysia for REE refinement of its Australian mineral concentrate.

The reasons that only a handful of deposits are in production are down to a range of factors, chief among them being that they are targeting conventional REE ores such as monazite and bastnasite. They have been proven to be economically viable extractable.

Geopolitics and cleaner future strategy

The main reasons for the steep price increase have been market demand-driven, but also geopolitical and environmental, social, and governance (ESG) in strategical nature, with a generally high ESG production footprint with additional costs for mitigation.

The anticipated deficit of REE magnet supply is a powerful driver of price increases as the world moves towards zero emissions policies. The fear of the potential deficit in REE magnet material supply has had a clear socio-economic impact, and supply chains remain complex and easily disrupted.

Supply from China is monopolistic and untransparent, but global dependence on imports from China is widespread, and there is an increasing domestic demand in China. Underinvestment in ex-China value chains has exacerbated the supply problem.

Project information

Prime location

The Eureka REE Project is situated in the heart of the Erongo Region of Namibia – or the ‘mining corridor of Namibia’. Neighbouring mines in the region include Rossing Uranium and Navachab Gold.

E-Tech Resources is currently singularly focused on developing its Eureka Rare Earths Project, approximately 250km Northwest of Namibia’s capital city Windhoek and 140km East of Namibia’s main industrial port Walvis Bay.

The project is favourably located in a sparsely populated, semi-arid, flat topographical area within 2km of the Trans-Kalahari tarmac highway, which provides tarred road links between Walvis Bay on the Atlantic coast and Namibia’s capital city, Windhoek.

The country has a well-established infrastructure with paved highways, railways, power, and water, all close to the project. A high tension, 200 kV AC power line runs near the project, with a substation approximately 10km to the SSE.

The Eureka deposit lies in the Southern Central Zone of the Neoproterozoic Damara Belt, within Exclusive Prospecting Licence (EPL) number EPL 6762, which covers Eureka Farm 99 and Sukses Farm 90. Namibia is mining-friendly, with a clear and transparent mining code for the entire project lifecycle (exploration, development and construction), and is internationally recognised as one of the African continent’s most social and politically stable jurisdictions.

Namibia has a strong history of mining and exploration; skilled professionals and drilling and exploration services are readily available within the country. The country’s local mining skillset is a high standard, with an extensive literate and multi-lingual workforce.

The corporation continues to assess new project opportunities and expand its Southern African portfolio.

Discovery and geology

The outcrop of the geological asset was discovered in 2015. Exploration started in 2016 with ground magnetic and radiometric surveys over the known carbonatite outcrops to generate several drill targets.

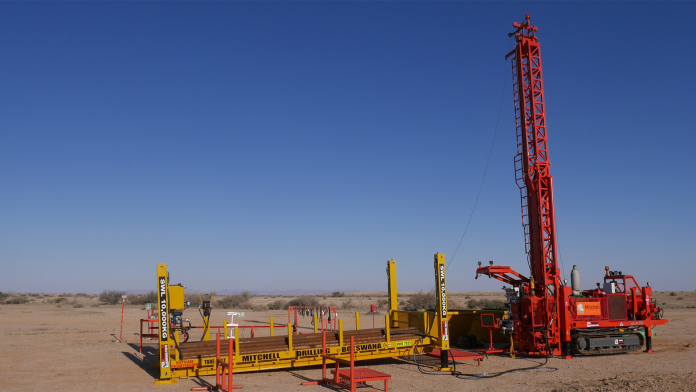

In March 2017, E-Tech Namibia completed 19 reverse circulation (RC) drill holes for a total of 610m in Zones 1, 2 and 3. During Q2 2019, 1.2km of trenching was completed on Zones 1, 2, and 3 and reconnaissance mapping located previously unknown mineralisation South of Zone 3.

At least fourteen en-echelon REE-bearing dolomite carbonatite dykes have been identified; these are found in four zones within several hundred meters of each other. The dykes are generally 0.5m – 4m thick. They are principally composed of coarse dolomite with a variable abundance of coarse low-thorium monazite as crystals up to 20cm in size (the host mineral of the REEs). Locally, the dykes are surrounded by a thin selvedge of skarn-like rock containing finer-grained monazite.

Current exploration status and highlights

E-Tech has continued to advance its exploration targets since issuing the MRE. Exploration work designed to expand the MRE to date from the first combined campaign includes 2,450m of trenching, 3,300m of RC drilling and 5,500m of Diamond Drilling (DD). RC and DD samples have been submitted for assay.

The first combined 8,800m RC and DD exploration campaign in Zones 1 and 2 ran from June to August 2021.

The second combined 5,000m RC and DD wider exploration campaign in Zones 1, 2, 3, and 4 started in December 2021 and was concluded in early February 2022.

Assay results of 7 out of 20 DD holes from the first campaign were released on 10 November 2021, highlighting interceptions with monazitic dykes up to 160m of vertical depth.

All RC assay results from the first campaign were released on 1 December 2021, which highlighted a significant lateral increase of the project’s footprint in terms of surface delineation of Zones 1 and 3 to South and West.

Assay results of the next 8 out of 20 DD holes from the first campaign were released on 10 February 2022, highlighting further interceptions with monazitic dykes and suggesting connectivity between zones.

Further assay results from the first and second drilling campaigns are still expected in Q1 2022, dependent on lab processing time. All drill pad sites and trenches have since been rehabilitated.

Exploration development potential

The company has engaged LightDeepEarths (Pty) Ltd, South Africa, to conduct further mineralogical characterisation work across the domains identified at Eureka, and assist in the optimisation of the process beneficiation flow sheet.

The geological and resource block modelling as a basis for the following MRE update is expected to be accomplished during H1 2022.

Environmental, social, and governance for a cleaner future

E-Tech Resources is committed to the highest environmental, social, and corporate governance standards to achieve a cleaner future. ASEC Namibia has conducted an environmental impact assessment, and a state-approved environmental clearance certificate was obtained.

Corporate codes, policies, charts, and guidelines are strictly followed, and E-Tech Resources adheres to United Nations Sustainable Development Goals and Project Readiness Standards (by project due diligence).

E-Tech Resources works with the Global Rare Earth Association (REIA) as a member of the ESG Board and with the Critical Minerals Association (CMA), chairing their International Mining Committee. Life Cycle Analysis (LCA) project, one of the best ways to quantify impacts from proposed development and mining operations, will be supported.

E-Tech Resources has also installed its own Sustainability Advisory Board. Ongoing environmental and social impact assessment is being performed. Baseline environmental monitoring equipment has been installed at the Eureka site to monitor changes in the local environment ahead of the ramp-up of exploration works.

Project financing

The company is currently 75% financed from private equity. It is dual-listed with about 25% of its shares floated on the public equity market, with a primary listing at the Toronto Stock Exchange (TSX-V) under the ticker symbol ‘REE’ and a co-listing at the Frankfurt Stock Exchange (FSE) under the ticker symbol ‘K2i’.

Management team and board

The management team and advisory board consist of individuals with a long and successful track record within the REE and raw materials based value chains, with professional experiences in geology, exploration, mining, energy generation and human resource management.

Conclusion for a cleaner future

It has become increasingly clear that the world needs access to more REE resources as demand for NdPr oxide continues to grow exponentially. Rising NdPr prices have a chokehold on the market. The only way to overcome these factors is to tackle the problem at its source, independently identifying and capitalising on new supply chain solutions.

E-Tech Resources’ Eureka Project, with its apparent simple mineralogy, easy processibility, and simple operations, has the potential to be one of the simplest and most accessible sources of REE supply for the global market.

Bringing the Eureka REE Project online will help meet future demand and mitigate geopolitical factors that hamper the push to meet global green energy targets and the transition to a cleaner future.

Sources:

- SRK (UK), Competent Person Report with Mineral Resource Estimate, published September 2021

- SGS Mineral Services, mineralogical test work, 2017

- Edward Loye, various geo-scientific studies on Eureka Project, 2015 – 2022

- Sam Broom-Fendley, peer-reviewed publications on geo-mineralogical analyses of monazite bearing carbonatite, 2016-2022

- Argus Media, REE Outlook 2030, Oct 2021

Please note, this article will also appear in the ninth edition of our quarterly publication