Rita Craveiro, Faculty of Sciences and Technology, NOVA University Lisbon, discusses how using enzymes as biocatalysts can allow for a greener chemistry industry.

Chemicals or chemical processes are often identified as dangerous or harmful. However, despite this, chemists still want to replicate different natural processes and apply them in various areas. For instance, biocatalysis is used in chemical processes and industries, using enzymes to catalyse (accelerate) chemical reactions. Present in humans, plants and animals, enzymes are proteins that have the function of catalysing chemical reactions, enabling transformations that would otherwise take a much longer timescale to occur. Enzymes are involved in fundamental processes such as digestion, DNA replication and breathing, and therefore they arguably sustain life as we know it. However, enzymes are also present in our daily life, in the most unexpected places. Detergents have enzymes, the food and paper industry uses enzymes, among many others.

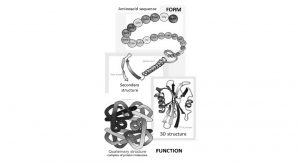

Enzymes are proteins that are composed of amino acids which have a catalytic role. They are divided into classes, according to the type of reactions that they catalyse, capable of breaking and forming chemical bonds, transferring chemical groups and electrons, without consuming or affecting the products formed. The seven different classes of enzymes are oxidoreductases, transferases, hydrolases, lyases, isomerases, ligases and translocases, and their names derive from the different chemical reactions that they catalyse.

Structural chemistry advances allowed for the study of these proteins and established that enzymes have specific mechanisms that allow them to function. Enzymes’ possess an intricate 3D structure, and have an active centre formed by specific amino acids. In a reaction medium with substrates and enzyme, substrates diffuse into that active site and are recognised by it much as a lock-key mechanism. When the reaction takes place, the products are then diffused into the medium as they are being formed. This process is of course affected by the conditions of the medium surrounding the enzyme, such as the temperature, pH level or water amount.

Many catalysts can be employed in chemical reactions, such as metallic based catalysts, having high reaction yields. However, these types of catalysts usually result from synthetic procedures, which are time consuming and use auxiliary solvents and chemicals, leading to accumulation of waste. Enzymes on the other hand can be produced in a simpler and more sustainable way by microorganisms. Enzyme production is nowadays an optimised procedure, and there are many companies that produce and have catalogues of different classes of enzymes which are readily available and have a high purity, (such as Novozymes).

The pros and cons of biocatalysis

The main advantage of using enzymes relies on its specificity. This means that an enzyme is able to catalyse preferentially a reaction for a given substrate, leading to no side-reactions, and highly pure products. The high specificity of enzymes can optimise processes at the same time it reduces waste. Moreover, because most enzymes have its optimal activity at moderate temperatures and pH values, this also means that there is no need to use high temperatures, and in turn reduces energetic and monetary costs of the processes.

However, the downside of using enzymes is mainly related with their high cost compared to other catalysts, consequentially hindering large scale applications. There is also the question of providing the enzyme with the appropriate medium conditions needed for it to be active. Nevertheless, there are effective strategies that deal with this question. Biocatalyst immobilisation allows for the re-use and preservation of an enzyme, allowing it to be active for a longer time without compromising reaction yields. There are various enzyme immobilisation techniques which can be achieved by covalent bonding, electrostatic adsorption or entrapment. Continually, there are also many different types of immobilisation supports (such as porous powders, membranes or fibres) and these can be made from different materials that can withstand milder or harsher reaction conditions, allowing it for a tailor-made immobilisation procedure.

Enzymes’ function is a delicate equilibrium, which can be disturbed by the presence of inhibitors. These inhibitors are species that can bind to the enzyme, affecting its structure and consequently the mechanism by which they catalyse a reaction, and this reflects in different reaction kinetics. This can be circumvented, by assuring that the enzyme is its optimum medium, but also by producing bio-engineered enzymes by altering the microorganism protein production mechanism.

Green chemistry and biocatalysis

Since the 1980s, efforts have been made in order to increase the sustainability of chemical processes by changing the way as one designs them. The 12 principles of green chemistry are guidelines aimed at preventing and reducing waste and using renewable and safer chemicals. The use of enzymes as biocatalysts fulfils much of the stated in these 12 principles. One good example of how the use of an enzyme can increase the sustainability of a process is the production of biodiesel. The conversion of animal or vegetable fats into fuel is achieved via an esterification or transesterification reaction. The triglycerides contained in the fats are esters that can react with alcohols such as ethanol and produces esters that can later be used as fuels. This reaction is normally carried out by adding a basic catalyst such as concentrated sodium hydroxide, achieving high yields. Concentrated sodium hydroxide is dangerous and needs to be chemically treated before being discharged. Enzymes such as lipases, normally immobilised, are able to catalyse this reaction achieving similar high yields. However, because the enzyme is immobilised, it can be packed into a reactor and the reaction can then take place in a continuous mode. The lipase can also be reutilised, without having to deal with highly basic solutions which pose a safety and environmental hazard.

Usually enzymes are used in an aqueous medium, but there are many types of substrates or reactions that do not take place in water or in aqueous compatible media. Enzymes have the ability of being active in different organic solvents such as hexane or octane, but it was found that they are also active in more sustainable solvents such as ionic liquids, deep eutectic mixtures and supercritical fluids. This adaptability allows for enzymes to catalyse reactions in different solvents, and to design greener reaction routes.

Enzymes in industry

Enzymes are used in various industry sectors and are used most widely throughout the food and detergents industries. When it comes to the food industry, one example of the use of enzymes at the industrial scale is the use of glucose isomerase. This enzyme catalyses the conversion of D-glucose into D-fructose, and D-xylose into D-xylulose, and is used for the production of high fructose corn syrup, a sweetener used in many different food products (e.g. sodas, candy, yogurts, dressings, bread, and frozen pre-prepared meals).This syrup, derived from starch, needs to have specific ratio of glucose/fructose, and this is achieved using the enzyme, glucose isomerase. The enzymatic process is operated by companies in USA and Japan, and they have a very high market share which demonstrates that enzymes do have a place in profitable industries.

A different enzyme, alfa-amylase, which is the enzyme contained in our saliva, also finds uses in the food industry. This enzyme catalyses the breaking of oligosaccharides in carbohydrates that helps in the digestion and assimilation of carbohydrates in humans. However, alfa-amylase is also used industrially as an additive to increase the shelf-life of bread and bakery products by preventing staling of these products.

A different large-scale application of enzymes is in the detergents sector. Almost all detergents, whether for household or industry uses, contain enzymes (i.e proteases, cellulases and lipases). These enzymes are able to breakdown dirt from different origins, and are used in laundry detergents, dishwashing detergents or even in textile production. Detergents benefit from having enzymes, since it allows them to be efficient at mild temperatures, reduces the amount of different chemicals to be used, and most importantly reduces the hazard in the produced effluents. Enzymes in detergents can reduce costs and are also more sustainable.

Rita Craveiro

Researcher

LAQV at REQUIMTE – Faculty of Sciences and Technology / NOVA

+351 212949681

rita.craveiro@campus.fct.unl.pt

https://sites.fct.unl.pt/biocatalysis_and_bioenergy

Please note, this article will also appear in the first edition of our new quarterly publication. Subscribe to our updates for free here.