A team from the Southwest Research Institute has developed a mechanical testing device to examine friction and wear associated with electric vehicle fluids.

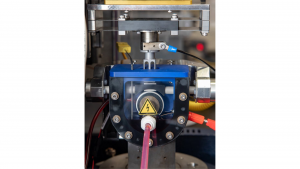

The Southwest Research Institute team modified a commercial tribology testing device to allow it to evaluate the impact of electric currents in fluids. The device can measure the wear and friction associated with electric vehicle fluids in the presence of an applied voltage.

The importance of testing electric vehicle fluids

As the transport sector transitions towards its electrified future, it is crucial that electric vehicle fluids are specifically created to tailor to the performance requirements of the electrical components in electric cars.

“The electrification of the automotive industry has accelerated over recent years, with future projections showing an exponential growth in market share for both light and heavy-duty applications,” said Cole T Frazier, a research engineer with SwRI’s Advanced Drivetrain Lubricants Section.

“Traditional fluid testing tools, however, were not developed to effectively analyse lubricant properties in electrified environments. That extends to tribology testing as well.”

Tribology is the study of friction, lubrication, and wear, and is conducted to evaluate the characteristics of vehicle fluids. Developing specific electric vehicle fluids is essential to ensure that performance can be boosted, guaranteeing that electric cars are efficient for the world’s clean future.

However, testing electric vehicle fluids is challenging as the presence of an applied electrical potential at component and lubricant interfaces prevents successful evaluation.

Overcoming testing challenges

To successfully test electric vehicle fluids, Dr Carlos Sanchez, a senior research engineer in the Tribology Research and Evaluations section at SwRI, designed a new test apparatus, built around a traditional universal testing machine, to model the effects of electrification on rotating parts. Throughout the project, the team further developed the setup and test protocol.

The majority of electric vehicles use permanent magnet motors or alternating current (AC) induction, powered by onboard battery packs. The direct current (DC) voltage input from the batteries is converted by an inverter to the AC power required to run the vehicle’s motor.

“The numerous rotating surfaces within EVs are exposed to voltage spikes during the DC-to-AC conversion process,” said Sanchez. “The spikes and the inherent electric field in high-voltage environments can allow electric currents to flow through the surfaces, damaging the electric vehicle fluids and materials that keep them moving smoothly.”

The speed of the DC-to-AC frequency conversion can cause local voltage spikes that require grounding. As motor bearings are located near voltage spikes, they are often susceptible to electric currents flowing through them. The electric potential for the bearings can build until the voltage breaks down the thin film of electric vehicle fluid, separating the small ball bearings from the bearing raceways or bearing shells. This can cause surface damage and scarring.

The team created and examined a test protocol for the new instrument

The new protocol developed by the researchers would best represent the actual system and produce relevant results. Using this advancement, the team tested several different commercial electric vehicle fluids and assessed wear scarring and friction on the bearing raceways and bearing shells. The team discovered that electric potential across a fluid, whether the current is AC or DC, can affect wear and bearings friction by as much as 20%.

“SwRI specialises in creating custom tribology rigs and testing capabilities to allow the industry to test multiple lubricant formulations efficiently, without requiring full-scale testing,” said Lee, who leads SwRI’s tribology activities.

“In this case, because lubricant breakdown is shown to be fluid-dependent, formulators can optimise their lubricants for specific EV drivetrains. SwRI’s bench-scale testing capabilities will accelerate lubricant optimisation, improving durability and increasing vehicle range through reduced friction.”