Osisko Metals is rapidly advancing the Pine Point Project, one of the most exciting zinc development assets globally with ready access to supportive infrastructure and boasting one of the cleanest concentrates.

Osisko Metals is poised to restart the Pine Point Project, one of Canada’s largest zinc and lead producers in the 1970s and early 1980s, as it looks to take advantage of a rapidly evolving zinc market.

The soaring zinc and lead market

After Canada added zinc to its critical minerals list, the United States followed suit. The US Geological Survey (USGS), in a recent report, is proposing both zinc and nickel be included in the redrafted critical minerals list as a result of re-evaluation of global supply chain security. This was drafted as zinc inventories declined globally and spot prices rose in a context where the US and several other nations, including the European Union, announced major infrastructure investment plans that will require zinc for galvanisation of steel components.

According to the USGS, nickel and zinc are the only two new additions to the US Critical Minerals List as refined zinc metal imports were relatively high at 710,000 tonnes in 2020, representing 83% of domestic consumption. Global supply chain trends make this problematic. “For zinc, the global concentration of mine and smelter production has notably increased during the past few decades,” the USGS said, adding that “this change has been driven mainly by increased production in China”. As more supply is concentrated in one country, the potential risk factors increase, particularly if that country is designated a mineral competitor, as is the case with China.

Zinc is an integral component of sustainable infrastructure spending through galvanisation (i.e. corrosion resistance) of steel parts, accounting for over 60% of zinc demand. With higher environmental and stringent sustainability criteria, average zinc usage is expected to increase across the construction, infrastructure and transport industries.

Current inventory levels remain extremely low and have dropped by more than 50% over the last five years. Further exacerbating the situation, North American supply production is expected to decline by over 35% in the next three years due to mine closures and falling production in older mines, highlighting zinc’s placement as a critical metal. There are very few high-quality zinc development projects in the pipeline to meet production shortfalls this decade.

Pine Point would also be a major lead producer alongside zinc production. Lead is more interestingly poised on the USGS supply risk table. LME inventories have dropped 75% in the last five years, again due to a growing concentration of global mining and smelting capacity in China. The USGS is ahead in analysing global supply patterns and the resulting potential threats to critical minerals availability compared to the European Union.

The Pine Point Project: A unique place in Canadian history

Lead-zinc showings south of the Great Slave Lake were known to the local First Nations long before any mineral claims had been staked in the area. During the Klondike Gold Rush, when groups of prospectors bound to the Yukon passed through Fort Resolution, the local fur trader Ed Nagle asked First Nations who traded at his post to bring any ‘shining stones’ they might find. In 1899, Nagle hired two prospectors to sink a 20-foot-deep shaft and collect samples at three different depths. Samples were sent to a lab in Vancouver, the Department of Mines office in Ottawa, and an assay lab in Seattle. Since the assays did not reveal any silver or gold, Nagle allowed the claims to lapse after three years.

In 1961, under the ‘Roads to Resources’ programme, an agreement was reached between the Federal Government, Pine Point Mines Limited (a subsidiary of Cominco Ltd. formed to finance Pine Point mine production) and Canadian National Railways, whereby the government undertook the construction of the railway to Great Slave Lake. Cominco Ltd. constructed a mine at Pine Point. The Northern Canada Power Commission agreed to build a 25,000 horsepower (approximately 18.6 megawatts) hydroelectric plant on Taltson River to supply power to Pine Point. In 1963, a townsite was laid out in collaboration with the Department of Northern Affairs and Mineral Resources. Cominco Ltd. built 53 homes, two 50-men bunkhouses, a recreation hall, and water and sewage systems. Shipments of high-grade material averaging 50% combined lead-zinc to Cominco Ltd.’s smelter in Trail started in 1964 and full mine production at a rate of 248,000 tons of concentrate per year began in 1965. During the 1970s, Pine Point was one of Canada’s leading zinc and lead mines. It rapidly became one of the most profitable zinc operations globally, cementing Pine Point’s place in history.

During the 1980s, mining proceeded to the West and deposits were found at greater depths. Mine development was hampered by the higher operational costs of the increased stripping ratio, haulage distance to the mill, and increased groundwater pumping requirements. Low base metal prices, high power consumption related to poor mine planning, and the acquisition of the Red Dog deposit with nearly double the average grades and better mining characteristics prompted Cominco Ltd. to close its Pine Point mining operation in 1986. Processing of stockpiled material continued until 1988.

A premiere zinc project

The Pine Point Project is located 60km East of the town of Hay River in the North West Territories, on the Southside of Great Slave Lake. The established infrastructure consists of an active power substation, paved GNWT highway access and 100km of pre-existing 25-metre-wide haul roads from the original mining operation that provide access to all major deposit areas. The town of Hay River is serviced by an airport, a paved road from Alberta, and host to a railway head operated by the Canadian National Railway.

A preliminary economic assessment (PEA) released in 2020 for Pine Point envisioned a mine with a life of ten years, producing an average of 327 million lb. of zinc concentrate and 143 million lb. of lead concentrate annually over its lifetime. This would make Pine Point the eighth largest zinc mine globally during its mine life. All-in sustaining costs are expected to average US$0.67 per lb. of zinc equivalent over the life of the mine. This cost profile would position Pine Point as one of the lowest-cost zinc mines globally.

Pre-production capital costs are pegged at C$555.7m, with C$458m budgeted for sustaining capital over the mine life. The resulting after-tax net present value is estimated at C$500m, based on US$1.15 per lb. of zinc and US$0.95 per lb. of lead and using an 8% discount rate, with a 29.6% internal rate of return and a 2.8-year payback.

Under more bullish scenarios, the project demonstrates even stronger economic returns and is well-positioned to benefit from a higher long-term zinc price. At US$1.25/lb zinc and $0.95/lb lead, the project returns an NPV of C$636.5m with IRR of 34.5% on an after-tax basis.

The proposed project will comprise 55 deposits (47 open pits and eight underground), one central concentrator plant site, and envisions the main electrical substation will feed 9 MW during the winter months and 12 MW during the summer. Hydroelectric power would be provided by the Northwest Territories Power Corporation will provide the power requirements through the Taltson hydroelectric grid. Additional power will be supplied by mobile LNG fuelled generators for the various mining sites requiring power and minimising the need for transmission lines for several open-pit mines that have a mine life of fewer than three years.

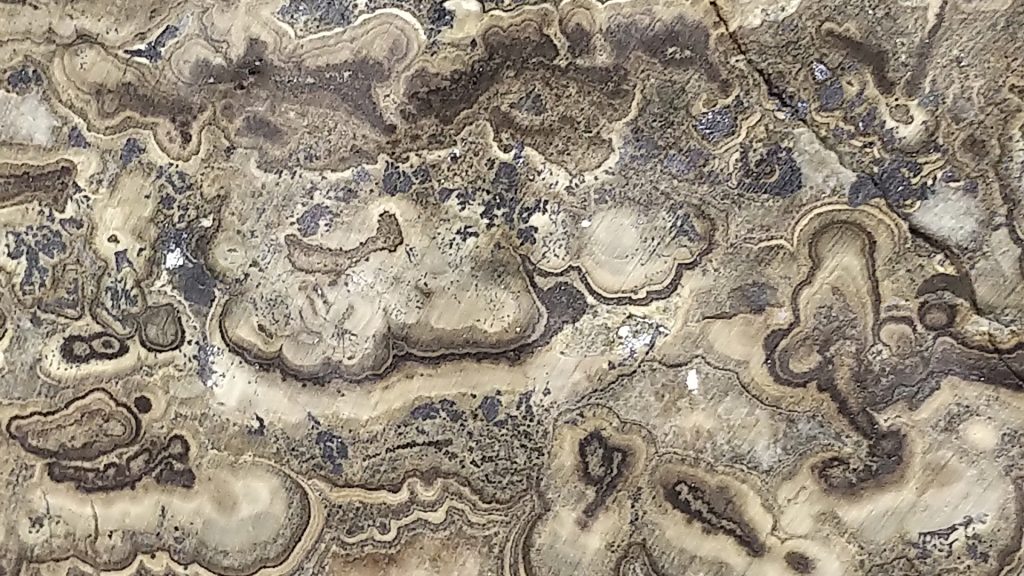

Unique to its peers, Pine Point would produce a zinc and a lead concentrate both of which are characterised by their ultra-high purity and grade. Osisko Metals does not anticipate any smelter or refinery penalties because these high-quality concentrates have very low deleterious elemental content. It is expected that this clean high-quality product will be sought after by nearly all smelters to dilute the deleterious contaminants in other concentrate feeds. Forecasted zinc supply going forward will be dominated by concentrates with high impurities which will require clean concentrates to blend and dilute the impurities of other concentrates. Final concentrate product from Pine Point would be hauled approximately 85km by truck to the intersection of Highway 5 and 2 to a transloading facility at Pine Point Junction. Concentrate will be sent to North American smelters by railway, and further afield to Asian smelters by bulk sea freight.

Ongoing hydrogeological modelling has identified significant reductions in the estimated water inflow rates into the proposed open-pit and shallow underground mines relative to the July 2020 PEA study estimates. New data confirms that underground water flow at Pine Point is preferentially controlled by sub-vertical structural discontinuities such as fracture zones or low displacement faults, with little evidence for significant groundwater flow from formational aquifers.

This will potentially reduce operating and sustaining capital expenditures associated with dewatering over the life of the mine compared to the 2020 PEA economic model for the Pine Point project. The new 3D hydrogeological model, dewatering volume estimates, and associated cost reductions will be incorporated in an updated PEA that is expected to be released in the first half of 2022.

Osisko Metals is currently drilling to test the extents of all deposits in the Mineral Resource Estimate (MRE) and to upgrade the Inferred Resources to the Indicated category so that they can be included in the Feasibility Study economic model.

Environmental initiatives to support green development

Power availability and fluctuation from renewable energy sources such as wind or solar present a significant impediment to mass adoption. Advancement in zinc-based energy storage solution technology could resolve natural renewable energy sources’ intermittent and unpredictable nature.

Zinc hybrid flow battery technology is expected to be a cost-effective alternative compared to lithium-ion or vanadium redox energy storage systems, allowing for the optimising renewable energy systems. Osisko Metals is evaluating the potential to store power for specific uses directly on-site through a zinc hybrid flow battery energy storage system coupled to the local hydroelectric grid or renewable energy sources, to maximise the use of green energy sources.

Osisko Metals Incorporated certain infrastructure advantages when designing the proposed Pine Point mine that is expected to significantly reduce the greenhouse gas (GHG) footprint relative to comparable projects. These advantages include:

- Ore sorting: Pre-concentration is expected to reduce the necessary concentrator size by approximately 40% by rejecting waste before entering the grinding/flotation circuit. By processing fewer tonnes in the energy-intensive portions of the metallurgical flow sheet, GHG would be reduced;

- Local hydroelectric power generation: Hydroelectric power would be provided by the North West Territories Power Corporation Taltson hydroelectric dam with a substation already located adjacent to the proposed concentrator location. This clean energy source would significantly reduce Pine Point’s GHG relative to other operations; and

- Rail access: The presence of rail within 70km of the Pine Point Project would allow for metal concentrates on reaching smelters in North America and abroad in an environmentally efficient fashion without relying on more carbon-intensive transportation such as trucking.

Osisko Metals has also initiated several trade-off studies to identify economically feasible alternative energy sources to complement the hydroelectric power available on-site from the local grid. The objective of these studies is to maximise the use of green energy sources with low GHG emissions at Pine Point. More specifically, Osisko Metals will evaluate:

- Natural gas: The 2020 PEA evaluated the use of natural gas to produce any additional energy needed for the project rather than using conventional diesel generators;

- Wind power: Using local elevation highs from waste rock piles produced during the Cominco Ltd. era could provide a better vantage point for capturing wind energy from northern winds crossing Great Slave Lake;

- Solar Power: Using double-sided panels to also capture reflected sunlight energy from the underlying snow in winter and the nearly 24 hr sunlight during summer; and

- Geothermal energy: Documentation prepared for the NWT government highlights the area on the South Western shore of Great Slave Lake as having high geothermal energy potential.

With these initiatives in place and inherent advantages to the project, Pine Point is well-positioned to mine sustainably.

Pine Point benefits from strong community support

The company has taken a proactive approach toward working and consulting with local communities that the project would impact. Consultation on the project with the communities was initiated in 2017 and has continued with frequent notifications on project activities, meetings, open house presentations and employment and contracting opportunities.

All communities support the project, with the mutual objective of maximising economic benefits, employment and training for local communities – specifically with a focus on employment and entrepreneurial opportunities throughout the various phases of the project.

The realised project would have a significant impact in the North West Territories, potentially generating over C$529m in combined federal and territorial tax revenue and contributing approximately 456 well-remunerated jobs during the production phase and around 280 jobs (peak of 400) during the construction period.

Pine Point: Leading the future

The lack of zinc investment in exploration and development combined with a shortage of significant new mines planned this decade would create a perfect storm for zinc and lead to higher zinc prices. Pine Point is one of the few essential undeveloped zinc assets with access to infrastructure, potentially producing one of the cleanest concentrates globally.

Please note, this article will also appear in the ninth edition of our quarterly publication