Scientists from Wake Forest Institute for Regenerative Medicine (WFIRM), USA, can 3D bioprint cartilage to treat those suffering from arthritis and knee injuries.

The team at WFIRM are able to 3D bioprint a type of cartilage, known as fibrocartilage, which helps to connect tendons or ligaments or bones and is primarily found in the meniscus in the knee.

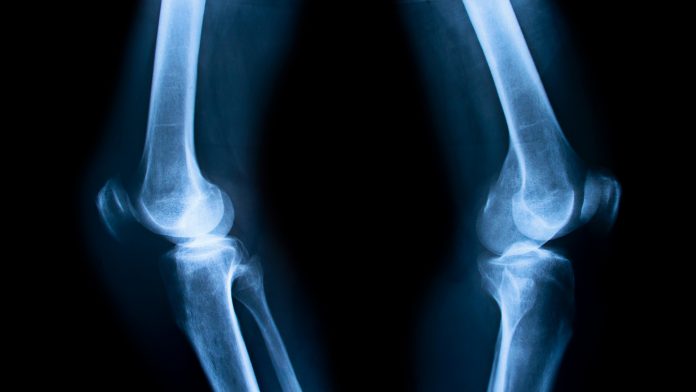

The meniscus is the tough, rubbery cartilage that acts as a shock absorber in the knee joint. Degeneration of the meniscus tissue affects millions of patients and arthroscopic partial meniscectomy is one of the most common orthopaedic operations performed.

The scientists at WFIRM have described how they are able to 3D bioprint a hybrid tissue construct for cartilage regeneration by printing two specialised bioinks together to create a new formulation that provides a cell-friendly microenvironment and structural integrity.

This work is done with the Integrated Tissue and Organ Printing System, a 3D bioprinter that was developed by WFIRM researchers. The system deposits both biodegradable, plastic-like materials to form the tissue ‘shape’ and bioinks that contain the cells to build new tissues and organs.

Sang Jin Lee, PhD, associate professor at WFIRM and author of the paper recently published by Chemistry of Materials journal, said: “In this study, we have been able to produce a highly elastic hybrid construct for advanced fibrocartilaginous regeneration. The results demonstrate that this bioprinted construct offers a versatile and promising alternative for the production of this type of tissue.”

For the study, Lee and his team tested various formulations and measured response to applied forces or stresses, the swelling ratio and the material strength and flexibility. One provided the proper cellular microenvironment to maintain the cells and help them grow while the other bioink offered excellent biomechanical behaviour and structural integrity. The final formula of the two bioinks used were co-printed layer by layer to create a mesh-like pattern. The constructs were implanted into a small animal model for observation for 10 weeks and evaluated at intermittent time periods, showing proper function.