With its wave motion-propelled Jospa Tug, Irish SME Jospa Ltd has developed a sustainable autonomous shipping solution.

Having worked in wave energy research and development for some years, Jospa Ltd discovered a novel way to propel a tug that produces significant bollard pull, using wave motion only. So we parked our promising wave energy convertor (WEC) projectto concentrate on developing the tug opportunity for sustainable autonomous shipping.

The growing efforts to combat pollution are incurring massive costs down the line; and this project addresses both the economic and environmental cost of burning fossil fuels to power commercial vessels in the maritime transport industry. Maritime transport emits around 1000 million tonnes of CO2 annually and is responsible for about 2.5% of global greenhouse gas emissions, with the majority of these emissions produced by large vessels such as oil tankers and cargo ships. If the status quo continues, shipping emissions are predicted to increase between 50% and 250% by 2050, depending on future economic and energy developments.

The European Commission’s 2011 White Paper on transport suggests that CO2 emissions from maritime transport in the EU should be cut by at least 40% from 2005 levels by 2050. Fossil fuel vessels are expensive to run and produce harmful emissions including CO, CO2, CH4, NOx, PM, SOx and NMVOC. For every 1kg (1.2 litres) of MGO used, 3.2kg of CO2 is produced.

What is the Jospa Tug?

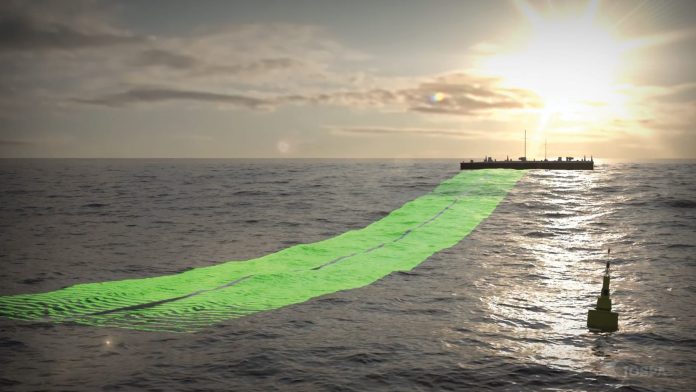

The Jospa Tug is unlike any vessel yet seen: it is a unique new zero-pollution, zero-emissions form of marine transport that can solve the growing problems of several sectors of the industry. Harnessing the amazing orbital velocity of waves, it can move with or against wave direction as desired, producing strong ‘bollard pull’ to handle big loads.

Eliminating fuel costs, the Jospa Tug is one of the new generation of sustainable autonomous shipping vessels. It will not have a crew, as multiple tugs will be controlled from a centre. It is highly survivable in storms. Its capital cost will be a fraction of competitors’ due to greatly reduced materials and the potential of mass production for various applications. Photovoltaic (PV) cells will be incorporated for navigation, control and occasional hybrid travel.

The eventual prime target market for the Jospa Tug is the transport of bulk goods, ranging from sands and aggregates to iron ores and bauxite. These are markets where tight margins make the cost of shipping crucial and speed is less important. Other niches include transport of water, diversion of glaciers, slow trawling, seaweed harvesting, holding drill platforms on station, pulling distressed vessels away from rocks and cleaning up the gyres of plastic waste in the oceans.

The tug consists of a central structural ‘spine’ (in fact we now favour a 3-spine approach) with horizontal or vertical hydrofoils or ‘fins’ attached. The spine(s), which are the structures that carry the fins, will be like a special hose made of the recyclable thermoplastic elastomer, reinforced with steel, to give high tensile strength coupled with flexibility to largely conform to waves. Selected strands of steel reinforcements from the spines will carry the attachment of the fins. A small ‘pilot’ is used in front of the Jospa Tug, with very low power electric drive from PV panels and a battery. It has two functions. First, it gives a slight pull to straighten the spine and initiate the fins so that the tug starts to move. Second, it is the main control for steering and the control centre for communications, signalling, possibly control further of fins as the tug grows in sophistication.

It is too early to attempt reliable estimates, but the simple nature of the construction of the Jospa Tug, featuring multiple identical fins and the absence of an engine, make it amenable to mass production and thereby render it extremely competitive. Scaling up the concept test model suggests a full scale weight of only 151 tonnes. When its simple materials and weight are considered, it is clear this will be an amazingly inexpensive machine.

How does it work?

Waves travel by passing on their momentum, like a line of stationary cars hit from behind at traffic lights. They do this in circular motions clockwise in their direction of travel. The force vectors are strongest at the water level, getting weaker as you go deeper.

The Jospa Tug’s fins are pivoted from its spine: each has a restraining cable that allows it to swing down in one direction only to 900. Going forward with the wave direction, the fins around the troughs lie up parallel against the tug’s spine at sea level; and the force vectors, moving backwards against the direction of travel, simply pass over them. Wave and Jospa Tug both travel in the forward direction.

The Jospa Tug travels equally well against the wave direction: when it is turned through 180 degrees to face back into the waves, the drive force will come on the fins at the troughs, which will swing downwards and be forced in the backwards direction. The fins at the crests will idle, parallel with the tug’s spine. The tug moves against the wave direction almost as quickly as with it.

The tug travels with the waves or against them at nearly the same speed and within 45 degrees to port or starboard of both directions, operating on wave power alone. Other important features of the tug include high bollard pull and effective adherence to its set direction, while the fact that the tug is largely submerged means its survivability in storms is comparable only to that of a submerged submarine.

What is its stage of readiness?

The Jospa Tug is at ‘the end of the beginning’ of its development: the theory has been investigated through modelling simulations to validate it; and highly successful proof-of-concept tests have been conducted. Our consultants DOC reported on the proof-of-concept tests, saying: “The encouraging towing force and vessel motion prototype results have shown that the mechanism is valid and has the potential to generate useful performance in a variety of sea states.”

EU study assistance will help with focus and setting the technical parameters

The tug offers a myriad of possible benefits, to the extent that with our limited resources it could be difficult to make choices from them. We are thus fortunate to have an EU-funded Marine Energy Alliance study running which will examine technical issues and advise on the prioritising of the range of opportunities on offer.

This study is being carried out under two main headings: TECHNICAL by the Maritime Research Institute Netherlands (MARIN) and INNOSEA; and COMMERCIAL by the Dutch Marine Energy Centre (DMEC) and University College Cork (UCC). The European Marine Energy Centre (EMEC) is project co-ordinator. There are so many facets of how the tug may benefit the marine transport industry that the EMEC’s assistance and its plan to discuss with live operators will be invaluable.

Potential applications for sustainable autonomous shipping

Clearing the oceans’ gyres of plastic wastes

The likely first role of the Jospa Tug will be tackling the oceans’ plastic waste gyres: we believe there is no better solution currently available, particularly when combined with our elegant beach plastics collection solution – with amazing serendipity, the Jospa Tug and the ‘Beach’ have arrived almost precisely as the world has become aware of these massive pollution problems. By slashing the production costs of recycling plastic waste, the use of such material can be accelerated.

Plastics can be combined with plant matter and burned as fuel; or more efficiently plastic waste can be turned into methane by anaerobic digestion. The sludge can then be used as a fuel or in low grade plastics mouldings.

The collection vessels, which will have belt presses on board to improve dry matter, will also act as maintenance bases with perhaps faster ‘ribs’ in tow. In order to avoid presenting a shipping hazard, we would intend to move repeatedly forwards and backwards on a straight line of hundreds of kilometres long. This will be at the centres of the gyres, areas which are not heavily populated with shipping traffic.

The ‘Beach’ is another Jospa invention, intended to complete the solution to plastics waste offered by the tug. It is modelled on observation and modification of beach action, enabling collection of plastic waste efficiently and at low cost. The tug and ‘Beach’ combine with an unmatchable synergy so that large numbers of them in arrays can cut wide swathes through the gyres of plastic waste. The low capital and operating costs of Jospa’s package for plastic waste can change the economics of recycling and stands out in front of all other attempts at solutions. It will be environmentally friendly; we will not be using a net except for the lifting of plastic and weed on to outbound transport. Instead a sloping beach concentrates the material which then enters a deep holding tube. We expect it to float as a sludge in this containment. Further down is a fine mesh net which will be used to lift the material on to a collection ship for further drainage and transport. How will it affect turtles and dolphins? It will be slow moving, about a metre per second; and is not expected to trap any fish. It is possible that seals might take up lodgings on the collector beach, but we expect we can design out this potential problem.

Our vision is an ocean garbage cleanup system where hundreds of Jospa Tugs with Jospa Beach plastic collection systems will continuously sweep thousands of square kilometres of rubbish gyres clean of plastics within a short number of years, before they all degrade into microplastics. Most plastic waste collection now is philanthropically funded; we believe that the lack until now of a pragmatic working solution has been a brake on the collection of waste. Given the solution we now offer, we believe that industry-sponsored collection and UN and governmental involvement is likely.

The big target: bulk materials

Using the advantages posed by its lack of fossil fuel emissions and crewing costs (aside from a land-based control centre) and demanding a very low first capital cost, the Jospa Tug’s biggest target to eliminate costs and pollution is the carrying of low value bulk materials such as sand and gravel to the sites of major projects; including huge volumes of bulk ores being moved between countries. In this case, logistics will need to be optimised by adjusting shipping frequency and stock levels to achieve minimum cost. This applies equally to bulk grain and the diminishing but still significant bulk delivery of bulk coal.

Slaking the great thirst for bulk water

Towing of water bags or even icebergs from areas of plenty of water such as Alaska to areas of drought such as southern California has been trialled in recent years. Fabricated water bags the size of football fields were towed from the immense pure river melt waters of the Arctic region. They invariably point to the cost of transport using conventional tugs as a crucial barrier. Slowness of movement is technically essential for such shipping, so the Jospa Tug is ideal.

There has been even greater and more active interest in the Gulf States, Saudi Arabia and South Africa in moving water from areas of plenty such as Antarctica to areas of drought such as the Arabian Gulf. Liquid water supplies for the Southern hemisphere are not as readily available as in Alaska, however: rivers are not as accessible; and icebergs present pumping and access problems compared to river water.

Clearing smaller icebergs from shipping lanes poses an increasing problem for seas around Arctic Canada. Here the Jospa Tug presents a low cost solution.

Effective sea anchors

A lightweight version of the Jospa Tug designed to keep stricken vessels from running onto rocks has the potential to avoid potentially massive pollution and costs. Such Jospa Tugs might be held at coastguard facilities and dropped off where needed by helicopter or carried on board as standard safety equipment. Similarly, a Jospa Tug could hold the pull on a positional drilling rig or ship to greatly reduce the amount of fuel used. The tug might be used to tow and reposition a drilling rig or a platform.

Slow trawling for fish

A high proportion of all fish caught in today’s high speed trawling is spoiled; and as controls on fishing methods become tighter there is an increasing case for low-speed trawling. In this application fresh fish would be handled and processed ready for market onboard a towed purposed barge. The waste and the habitat destruction would approach zero.

Ocean seaweed harvesting

We would not be the first to propose a wave powered pump system to elevate cold nutritious water from the deep near coasts up to the oxygen-rich and sunlight-drenched surface. This leads to very rapid sargassum growth on the sea surface, with attendant CO2 absorption and climate change mitigation. This can be harvested later, perhaps by our wave powered Tug and Beach collectors as biofuel. If the deep waters off the Gulf of Mexico are enriched with nutrients they will travel by the Gulf stream and eventually enter a gyre, for collection along with plastic oil and any dead floaters.

Sargassum seaweed

Sargassum could likewise be raised and harvested in significant quantities in the Southern oceans. Jospa Ltd already owns one patent which has been proven to be exceptionally effective in wave powered pumping which would be part of the production system.

Advantages and disadvantages

Compared with sailing, for example, the advantages of the Jospa Tug are its full two-way directional ability and its massive pulling power. Its speed cannot match the maximum speed of a sailing ship, but overall it would be more consistent and predictable. Above all, it is far more survivable than any sailing ship.

Are any breakthroughs required to make it work?

We believe not. Jospa has some novel items to incorporate, not yet disclosed, which will further improve the Jospa Tug; but all are essentially applications of sound marine engineering practice rather than novel untested theories. All the ancillary technologies required exist already or are well advanced and available through partnering.

The way ahead

With our size and resources, it would be a very long time before we could do justice to exploiting or developing the application’s opportunities. For this reason Jospa wishes to form a programme of growth through a mix of partnerships, licensing by application and geographic area; and including possible outright sale of technologies, again by application and by geography, joint ventures and alliances with shippers, with shipbuilders and consulting and technology companies, with relevant specialists such as operations centres, autonomous marine vessel specialists, equipment suppliers, materials companies – rubber, elastomer, reinforced hose – quite apart from our need for investors – will all be examined. Jospa would continue to provide technical development advice and IP protection.

Jospa expertise in wave energy to electricity

Low inertia rotational rectifier PTO

The key term here is ‘low inertia’ – as wave power is highly and almost instantaneously variable, such a responsive low inertia design is essential to minimise problems with gears and damage to the generator and to give high fidelity for irregular low speed movements.

‘Eite’ Wave Energy Convertor

Eite (Irish for “fin”) has excellent bandwidth, produces in a wide variety of waves big and small regular and irregular, one size suits all seas. Eite suits mass production with resulting cost benefit. Eite has a yet untested concept to shed load for storm protection.

Patrick Duffy

Jospa

+353 (0) 872556067