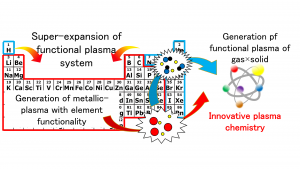

A team of researchers has successfully used solid metals under a strong magnetic field in a microwave resonator to create metallic plasmas.

Hot gases composed of metal ions and electrons, called plasmas, are widely used in many manufacturing processes, chemical synthesis, and metal extraction from ores and welding. The new method, created by teams from Tohoku University and the Toyohashi University of Technology, is one of the most efficient in creating metallic plasmas.

The study’s corresponding paper, ‘Metal ion plasma generation under strong magnetic field in microwave resonator,’ is published in AIP Advances.

How does the process differ from traditional methods?

A strong electric field is applied to gases or liquids in the most conventional methods for making metallic plasmas. However, this can require copious amounts of energy.

More recently, microwave radiation has also been harnessed to generate plasmas as it converts atoms into a form that can more effectively drive desired chemical processes, among other advantages. The metallic plasmas microwaves generated are now used in commercial operations, including semiconductor manufacture, diamond deposition, and releasing metal from their ores.

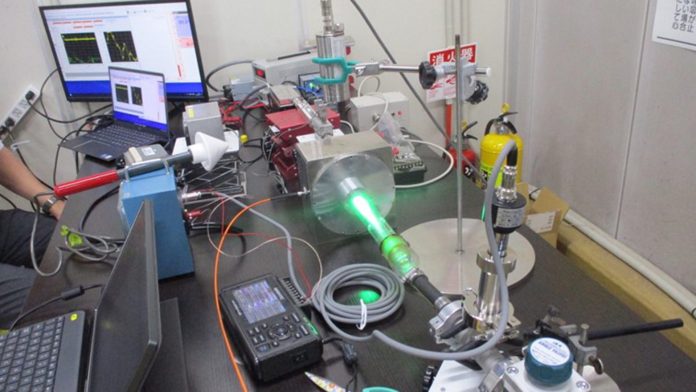

However, this has involved multi-mode microwave generators, which generate a chaotic distribution of microwaves. One key advance the team achieved is applying a single-mode microwave generator to produce their metallic plasmas. This creates more controlled and highly focused microwaves.

“We expect our process could significantly improve the efficiency of plasma techniques in many applications and enhance profitability in the commercial arena,” explained Jun Fukushima, who developed the technique along with electronic engineer Satoshi Fujii.

“Metallic plasma generation through microwave excitation has gained considerable interest”

Using magnetic fields to generate plasmas has attracted considerable attention from scientists. The new research enhances our understanding of new material processes and how they can be stabilised.

In their paper, the researchers stated: “Plasma is widely implemented for welding and other applications; it is generated and maintained from gases using various methods, such as DC discharge, capacitive discharge, inductive discharge, microwave discharge, and ECR.”

“Among these methods, the generation of metallic plasmas through microwave excitation has gained considerable interest since it enables the generation of radical atoms required for efficient chemical reactions. It also enables the use of the luminescence spectra of the elements.”

Overcoming challenges

One significant challenge the researchers encountered was that their initial plasmas could only be stabilised for up to ten minutes. Therefore, they redesigned the equipment, eventually achieving much longer stability. The final and more innovative system contains a double quartz tube, with the solid material converted into metallic plasmas sitting within the inner tube.

The researchers expect their technology will be beneficial for extracting pure rare earth metals from their ores. These metals, such as cerium, lanthanum, and neodymium, are becoming widely used in large-scale applications, including the manufacture of rechargeable batteries for electric vehicles. The Tohoku University and the Toyohashi University of Technology team have already demonstrated this, using a plasma of calcium and magnesium to release scandium and vanadium atoms from their oxide ores.

“This is a new and unconventional method for utilising metallic plasmas, which we consider to be crucial for reducing the energy requirements for future materials science applications,” Fukushima concluded.