At the Institute for Materials Technology and Plastics Processing (IWK), we specialise in delivering innovative approaches for all your polymer research needs.

Our core focus thereby is to advance technology and enhance sustainability and circularity across the plastic value chain.

Plastic products are integral to our daily lives, with production levels continuously rising. However, in light of the current global environmental challenges, there is an urgent need for innovative solutions to enhance materials and processing technologies and transform the plastics industry towards circularity and sustainability.

At the IWK, we are dedicated to assisting companies in navigating these challenges and driving sustainable progress. Founded in 2005, our institute is the leading research institution in Switzerland for component design, plastics production, and recycling.

Our diverse projects demonstrate how the synergy between research and industry can lead to pioneering innovations:

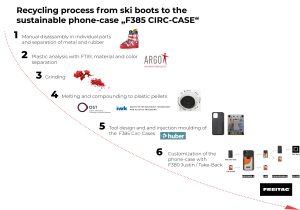

From ski boots to sustainable phone covers with advanced mechanical recycling

The F385 CIRC-CASE IPHONE®, a phone cover made from discarded ski boots, demonstrates the feasibility of a closed-loop recycling process within a 150km radius.

The process was developed by the IWK together with FREITAG®. It comprises collecting and sorting end-of-life plastic products in cooperation with ARGO, a workshop for people with disabilities, in Davos.

The pre-sorted parts are then shredded and processed in the compounder at the IWK to remove contaminants and produce homogenous pellets.

These pellets are used to manufacture iPhone covers made of 100% recycled TPU via injection moulding. At the end of their life, these covers can be recycled again through Freitag’s Take-Back system.

Areas of expertise

The competence spectrum of the IWK is divided into the following research fields – Injection moulding, Compounding & Extrusion, Composite technology, Joining technology, Simulation and Design, Metal manufacturing technologies, 3D-Printing / Additive Manufacturing, Material analysis and Component testing.

They bring together extensive expertise in materials, component development, and processing technologies throughout the entire plastic value chain:

Materials

Development, characterisation, testing and damage analysis of thermoplastics, composite materials, light metal alloys and adhesives.

Component Development

CAD and FEM supported simulation and design of plastic and composite parts as well as manufacturing processes.

Processing Technologies

Excellently equipped machine park comprising a twin screw compounder, blown and cast film lines, various injection moulding machines, and 3D printers, as well as equipment for the production of composite parts, metal manufacturing, and joining of materials.

Towards a sustainable and circular plastics industry

IWK is leading the charge in creating sustainable solutions within the plastic value chain. Our innovative projects exemplify our commitment to enhancing circularity.

By harnessing our extensive expertise in various research fields, we empower businesses to tackle the challenges facing the plastic value chain while promoting responsible recycling and sustainability.