Bacteriophage production could be the secret weapon in helping us combat antibiotic-resistant infections, but they can be challenging to produce.

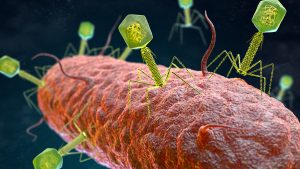

Bacteriophages, also known as ‘phages’, are viruses that only infect bacteria and exist everywhere that bacteria live.

Phages are the most abundant organisms on the planet and have evolved over millions of years to be highly selective about the bacteria that each phage will infect and kill. With cases of antimicrobial resistance (AMR) increasing significantly across the globe, the use of phage as a weapon to combat antibiotic-resistant infections is growing rapidly.

At Cellexus, we are passionate about developing solutions to help us overcome this huge threat to health, and our CellMaker bioreactors are perfect for phage production.

Finding an optimal balance for bacteriophage production

Using conventional methods, it can be challenging to produce phages consistently and at high concentrations (titres), which presents challenges in translating results to clinically and commercially viable solutions.

CellMaker provides the optimal balance of low-stress mixing with exceptional gas exchange and nutrient distribution needed to produce high-quality active phages in their typically fast-growing host bacteria. We uniquely achieve this in single-use bioreactor bags, employing a carefully controlled curtain of bubbles to both aerate and mix the bioreactor contents, providing the perfect conditions for cells and phage to grow.

Our customers routinely achieve 10-100x higher titres of phage when using CellMaker compared to other methods, even with the most challenging host-phage combinations.

In addition to providing a blissful environment for cells to grow, our patented single-use, airlift bioreactors provide a number of key operational benefits over conventional bioreactors, specifically:

- Cost reduction: Eliminating laborious and costly cleaning, assembly and sterilisation processes commonly associated with other bioreactors means a system turn-around time measured in minutes rather than days. Simply swap in a new bioreactor bag, fill with media and go!

- Productivity improvements: In addition to negligible turn-around times, our single-use technology significantly reduces the amount of time that skilled scientists are committed to low-skilled activities, increasing the time available for higher-value activities.

- Ease of use: Routinely cited as the most user-friendly bioreactor available, CellMaker makes user training and adoption quick and simple.

- Versatility: Not just for phage! Culture various cell types, from plant to mammalian cells, in volumes from 1.5 to 50 litres, making scale-up and translation super-simple.

Serious about quality

At the heart of every CellMaker system are our patented single-use airlift bioreactor bags, which have been designed to meet the most demanding research and production requirements.

All bioreactor bag materials are fabricated and assembled in ISO Class VII clean room facilities and according to an ISO 13485:2016 certified and FDA 21CFR 820 compliant manufacturing process to ensure you work with a consistently high-quality product.

Once double-bagged and gamma-irradiated, CellMaker bioreactor bags are stored and dispatched to you according to a robust, ISO 9001:2015 accredited quality management system that provides you with ultimate peace of mind.

Further details, quality certificates, and data are available upon request.