Invicta Water is at the forefront of developing innovative technology to effectively remove and destroy PFAS (per- and polyfluoroalkyl substances) from water sources.

As PFAS contamination poses significant environmental and health risks worldwide, traditional treatment methods such as GAC, ion exchange, and reverse osmosis, while useful in capturing these chemicals, fall short when it comes to complete destruction.

These methods are often costly and generate hazardous waste that requires complex disposal, with estimates suggesting that remediation costs in the US could reach $500bn – about 10% of annual federal tax revenue.

Limitations of current technologies

Current techniques primarily focus on capturing PFAS rather than destroying them. Incinerating spent filtration media to eliminate accumulated PFAS can lead to secondary pollution, as historical treatments produce large quantities of contaminated waste—approximately 200 tonnes annually for medium-sized GAC plants.

The tiny size of PFAS molecules makes removal challenging; extracting just one pound from 120 million gallons of water exemplifies this difficulty, rendering it a “needle in a haystack” problem that is further complicated by logistical and transportation costs.

Invicta Water’s revolutionary PFAS destruction solution

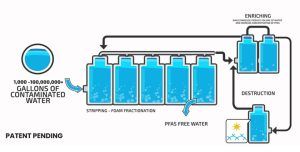

Invicta Water introduces a groundbreaking process that utilises air, water, light, and specially engineered crystals to not only separate PFAS from water but also completely destroy it. The core technology is Foam Fractionation, a process in which air bubbles in water attract PFAS molecules, creating a foam that can be easily separated. This significantly reduces the volume of contaminated water, focusing the contaminants into manageable waste streams.

After initial separation, the remaining PFAS-laden foam undergoes a multi-phase treatment:

- Stripping phase: Utilising an innovative, patent-pending Foam Fractionation process, PFAS molecules are extracted from water, resulting in a PFAS-free effluent. The waste foamate contains captured PFAS, comprising less than 5% of the original volume.

- Enrichment phase: The foamate’s volume is further reduced, concentrating the PFAS from parts per trillion to parts per billion. This increased concentration heightens the efficiency of subsequent destruction, with some residual PFAS detected at trace levels in effluents.

- Destruction phase: The highly concentrated PFAS in the foamate is directed into a tiny reaction vessel. Here, boron nitride catalytic crystals, with a surface area equivalent to several football fields, interact with the PFAS molecules. UV light stimulates the crystals to emit electrons, initiating catalytic reactions that break chemical bonds and fully mineralise PFAS into harmless molecules, with no waste or hazardous byproducts produced.

This continuous, cyclical process ensures no residual PFAS remains, with recycled streams capturing any unreacted molecules for further destruction, making the system highly efficient and scalable.

Innovative chemistry

The key to Invicta’s treatment is the combination of UV irradiation with boron nitride crystals. When illuminated, the crystals emit electrons that react with PFAS molecules adsorbed on their surface, breaking bonds and rendering the contaminants fully inert.

This process operates under ambient conditions – normal room temperature and pressure – which reduces energy requirements and operational costs compared to batch or high-temperature methods, such as Super Critical Water Oxidation or HALT.

Benefits of the Invicta system

- Regulatory compliance: Meets and exceeds strict EPA PFAS standards, making it suitable for large-scale municipal or industrial use.

- Operational efficiency: Utilises ambient conditions, reducing energy and infrastructure needs. Combines collection and destruction in one compact, scalable process.

- Environmental safety: Produces no hazardous waste, eliminating secondary pollution and disposal challenges.

- Cost-effectiveness: Minimal footprint, low energy consumption, and simple operation translate to significant cost savings, especially critical given the scale of PFAS contamination.

- Versatility: Effective for vast volumes from hundreds to hundreds of millions of gallons making it adaptable to various treatment scenarios.

A leading solution for combatting PFAS pollution

Invicta Water’s Photocatalytic Destruction (PCD) technology offers a transformative approach to PFAS remediation. Its ability to accomplish over 99% reduction without waste generation, coupled with low operational costs and environmental safety, makes it a leading solution for addressing the PFAS crisis.

As regulations tighten and awareness grows, Invicta Water’s innovative process positions itself as a sustainable, efficient, and scalable method to safeguard water quality now and into the future. Through ongoing R&D, Invicta continues to pioneer advancements toward a cleaner, healthier world.

Areas of application

- Drinking water

- Wastewater

- Industrial wastewater

- RO waste processing

- AFFF remediation

- Private wells

- Home systems