New 3D printing machines developed by the UKAEA offer new opportunities to produce highly specialised fusion components.

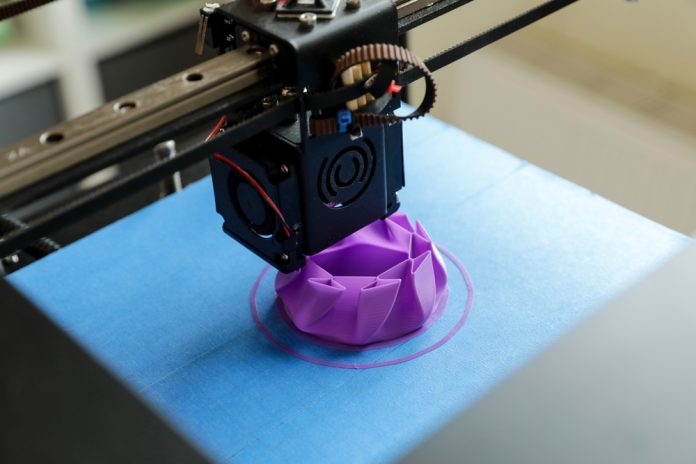

The United Kingdom Atomic Energy Authority (UKAEA) has begun using two additive manufacturing (3D printing) machines that use complementary methods to manufacture components for future fusion machines.

At the recently opened Central Support Facility (CSF), the UKAEA has commissioned an electron beam 3D printing machine, which will primarily be used to incorporate tungsten into components, alongside a selective laser manufacturing machine.

Overcoming fusion machine challenges with 3D printing

Fusion energy is set to play a key role in a global low-carbon energy future. However, the components within future fusion power plants will need to operate under complex and challenging conditions, including extreme temperatures, high neutron fluxes, and intense magnetic fields.

As a result, they require complex combinations of materials and precision engineering.

Additive manufacturing is well suited to producing materials with intricate designs, and in low volumes, making it ideal for a sector such as fusion, where each fusion machine will be highly individual and require bespoke components.

As a result, UKAEA believes that 3D printing can play a crucial role in the future of fusion, reducing the costs associated with precision manufacturing. The organisation has commissioned machines to demonstrate two complementary additive manufacturing methods for producing fusion components.

Roy Marshall, Head of Operations for Fabrication, Installation and Maintenance, at UKAEA said: “Future fusion power plants will require thousands – or even millions – of components with complex geometries that can withstand the extreme conditions of a fusion environment.

“UKAEA believes that additive manufacturing will be essential to developing these components at a scale that makes fusion commercially viable.”

Manufacturing plasma-facing components

The first machine, the eMELT Electron Beam Powder Bed Fusion (E-PBF) additive manufacturing machine, will utilise electron beam technology to join tungsten powder into solid components with nearly 100% density.

The eMELT machine will be used to layer tungsten onto other materials, such as copper, chrome zirconium, stainless steel, and Eurofer 97, a special type of steel developed for use in fusion machines.

On the other hand, the SLM280 – Selective Laser Manufacturing – will be used to experiment with producing components with complex geometries and material combinations that are essential for successful fusion plants.

The SLM280 is manufactured by Nikon SLM, provided by Kingsbury Machine Tools, and supported by Additure.

Both 3D printing technologies will support the manufacture of plasma-facing components that will be exposed to extreme temperatures during their operational lifecycles. The machines will also reduce reliance on traditional techniques, such as welding, thereby reducing the number of manufacturing operations and joining processes.

Supporting fusion research and development with the Central Support Facility

The CSF combines this technology with purpose-built workshops in a single building, alongside the UKAEA’s Manufacturing Support Team and Special Techniques Group, to facilitate collaboration between manufacturing teams and support fusion research and development.

UKAEA is now working to prepare commercial partners for the large-scale production that is essential for the fusion energy plants of the future.

Both machines will now begin producing challenging geometries and undertake experiments to explore the properties of additive manufactured materials.

This work will be followed by the initial stages of manufacturing, involving the layering of tungsten and copper chrome zirconium.