A wastewater treatment facility in the US has deployed PerfluorAd™ for PFAS removal.

Per- and polyfluoroalkyl substances (PFAS) remain one of the most challenging water contaminants in the United States. Regulatory thresholds continue to tighten – most recently with national maximum contaminant levels (MCLs) of 4 ppt for PFOA and PFOS – while industrial and municipal treatment plants face increasing volumes of PFAS-laden wastewaters that often exceed tens of thousands of ppt. For waste processors, these pressures create operational bottlenecks, slowdowns, and escalating disposal costs.

A waste treatment facility in the Great Lakes region of the United States faced exactly these constraints. The plant routinely received high-margin industrial wastewaters containing 10,000–50,000 ppt of total PFAS, including PFOA, PFOS, PFNA, PFHxS, and shorter-chain fluorinated compounds. Although the facility operated a foam fractionation system (SAFF®), the elevated PFAS loads periodically overwhelmed the system, forcing throughput reductions and limiting revenue opportunities.

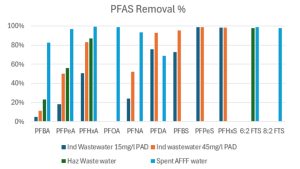

To solve this challenge, the facility integrated PerfluorAd™ – a plant-based PFAS flocculation and precipitation technology developed by Cornelsen. PerfluorAd acts selectively on PFAS and works particularly well for long-chain C8 chemistries, forming micro-flocs that can be separated easily by existing treatment equipment. The technology is already documented to achieve 80–98% removal efficiency in high-strength PFAS waste streams and up to 99% removal in several water matrices, as demonstrated in multi-country full-scale applications.

A simple enhancement with impactful results

One advantage of PerfluorAd is its ease of implementation. The Great Lakes facility required only minor dosing and mixing modifications, seamlessly integrating PerfluorAd into its existing pretreatment process. The technology’s chemistry, as shown in Cornelsen’s technical literature, is tolerant of complex backgrounds – including high DOC, high salinity, and variable pH – making it well-suited for this site’s diverse industrial waste inputs.

Once PerfluorAd was added upstream of the foam fractionation system, several immediate performance benefits emerged:

- Consistent throughput: PerfluorAd reduced PFAS concentrations entering foam fractionation, preventing system overloads. The plant no longer had to slow down operations during high-PFAS waste days.

- Improved PFAS treatment efficiency: With influent stabilised, the foam fractionation system could operate within its optimal design envelope, improving overall PFAS removal consistency.

- Increased revenue capacity: By preventing bottlenecks, the plant was able to accept and process more high-margin wastewaters – something that was previously limited by PFAS load variability.

The plant owner summarised the impact succinctly: “PerfluorAd works great. No issues. We are working to expand capability to other sites to take more high-margin waste in.”

Economic and environmental advantages

Traditional PFAS treatment methods – granular activated carbon (GAC), ion exchange, membranes, and thermal destruction – often carry substantial consumables and waste disposal burdens. PerfluorAd offers a contrasting model:

- Low waste generation, with PFAS concentrated into minimal volumes of sludge or solids.

- Biodegradable chemistry, breaking down into harmless compounds.

- Compatibility with existing separation assets, avoiding major CapEx.

- Low energy demand due to passive flocculation and simple mixing.

At this facility, the reduced load on downstream SAFF® equipment also decreased operational wear and extended system availability.

PerfluorAd’s low-volume sludge is particularly advantageous compared to alternatives. For example, at airports transitioning from aqueous film forming foam (AFFF) systems, conventional triple-rinse methods can generate entire totes of contaminated water, whereas PerfluorAd often consolidates PFAS into a single waste drum.

A replicable model for PFAS management in the US

This Great Lakes facility demonstrates how a simple upstream PFAS separation step can transform operational capacity. With PFAS regulations tightening across the US, and several states implementing their own aggressive MCLs, the need for scalable, cost-effective solutions is intensifying.

PerfluorAd offers wastewater treatment plants, industrial processors, and remediation firms an approachable, modular way to reduce PFAS loads while leveraging existing equipment. As this site plans expansion to additional locations, its successful experience represents a promising pathway for PFAS management nationwide.

Pamela Lynch, President of Cornelsen Inc, said: “At Cornelsen Inc., we’re building PFAS treatment trains that deliver practical, proven results for US communities. We’re early in our journey in the US, as Cornelsen scaled in 2025 to meet global demand, but our commitment to advancing safe, reliable water solutions is already taking shape. We are building on the decades of full-scale implementations across Europe and the UK.”