Challenges, opportunities, and Wisematic’s role in the future of smart device refurbishment.

The rapid expansion of the global secondary market for consumer electronics has established refurbishment as a central component of the circular economy. In Europe, where sustainability, resource efficiency, and carbon reduction are high political priorities, the refurbishment of smartphones and other smart devices is increasingly recognised as a strategic industry with high importance and long-term growth possibilities. This field sits at the intersection of several technological and operational disciplines: flexible robotics, machine vision, artificial intelligence (AI), reverse logistics, and materials circularity.

Refurbishment automation is not merely an extension of traditional manufacturing automation. It represents a distinct discipline with high focus on flexibility and adaptation—it must handle high variation, uncertain conditions, device-specific requirements, and rapidly evolving consumer technologies. Unlike industrial production lines optimised for predictable, uniform inputs, refurbishment facilities encounter a near infinite mix of device types, age profiles, physical conditions, and software states. This positions refurbishment automation among the most technically demanding automation domains.

At the same time, the societal and environmental stakes are exceptionally high. Maximising the lifespan of smart devices reduces electronic waste, preserves valuable raw materials, and provides consumers with affordable, high-quality alternatives to new products. As the industry grows, the need for scalable, standardised, and robust refurbishment processes becomes increasingly urgent. Automation is the only viable route to meeting this demand on an industrial scale.

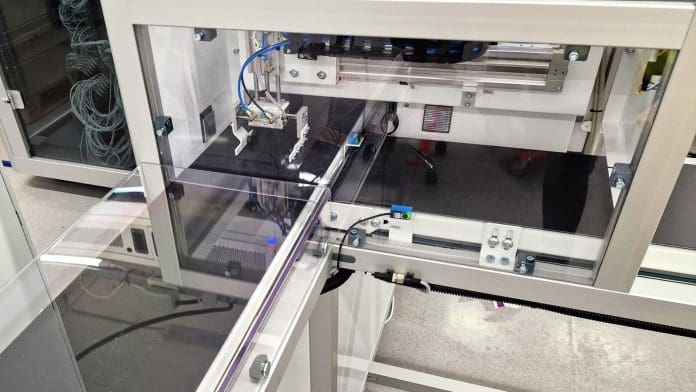

Within this evolving landscape, Wisematic — a Finnish automation company with deep roots in miniaturised, flexible automation solutions—has emerged as a pivotal innovator. Known originally for tackling complex, specialised engineering problems that many other system integrators declined, Wisematic has applied its expertise to one of the most challenging areas of refurbishment: automating early-stage device preconditioning.

This article outlines the challenges facing refurbishment automation, explains why progress in this field is crucial for Europe’s circular economy, documents Wisematic’s successes and hurdles.

The main challenges in refurbishment automation

Refurbishment workflows remain among the most difficult industrial processes to automate. Several inherent characteristics of used smart devices create technical, operational, and logistical challenges.

High diversity of devices and configurations

Smartphones have proliferated in form factor, design, and architecture. In a typical refurbishment centre, hundreds of different models may appear in a single day—each requiring different handling approaches. Key sources of variation include:

- Device dimensions, weight, and construction

- Connector types, orientations, and recess depths

- Button placement, bezel thickness, and screen curvature

- Battery state and safety conditions

- Operating system versions and security settings

Unlike traditional manufacturing automation, refurbishment automation cannot rely on predictable, uniform input.

Uncertain physical conditions

Each device enters the refurbishment line with a unique history. Damage or wear may include:

- Broken or shattered screens

- Bent frames

- Missing or detached buttons

- Degraded and swollen batteries

- Non-functional charging ports

- Cosmetic wear or deep scratches

Robotic systems must be able to detect these variable conditions and adapt their actions accordingly. This requires advanced machine vision, multi-sensor fusion, advanced mechanical arrangements and robust error handling strategies.

Wide range of required tasks

In the early phases of refurbishment—often termed the ‘preconditioning’ or ‘intake’ stage—operators must perform several device-specific tasks:

- Identification

- Visual inspection

- Physical alignment

- Plugging connectors or initiating wireless charging

- Launching diagnostics

- Monitoring data wipes

- Sorting, labelling and tracking each unique device

Automating this mix of cognitive, visual, and fine motor tasks remains extremely difficult. Human operators can intuitively adjust to each unique device; automation must replicate that adaptability in structured, reliable ways.

Rapidly changing device technologies

Emerging device types such as folding smartphones and wearable devices introduce new mechanical and sensing challenges to refurbishment automation. Foldables change shape mid-process and require careful manipulation to avoid damage. As the market continues to innovate—potentially moving toward modular, expandable, or shape-shifting devices—automation systems will need to anticipate and adapt to increasingly dynamic hardware behaviours.

Software and data erasure complexity

Secure data wiping is essential for GDPR compliance and consumer trust. Yet many devices require manual on-screen interactions during factory resets. Without standardised, universal device-level protocols for initiating secure erasure, refurbishers must resort to manual steps or custom-built robotic interactions, both of which limit scalability.

Why the development of refurbishment automation is important

Improving refurbishment automation is not only an operational priority—it is a strategic necessity for several overlapping reasons.

Environmental and resource sustainability

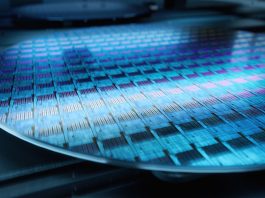

Extending the lifespan of smart devices significantly reduces the demand for raw materials such as lithium, cobalt, rare earth metals, and high-purity silicon. Automated refurbishment:

- Increases throughput

- Reduces backlog and device expiration

- Enables more devices to return to the marketplace

- Minimises waste from premature recycling or disposal

As Europe pushes toward circularity targets, refurbishment automation becomes central to achieving sustainable electronics policies.

Economic competitiveness and labour efficiency

Refurbishment is labour-intensive, and European refurbishers face high operational costs. Automation:

- Lowers cost per processed device

- Improves cycle time predictability

- Reduces ergonomic strain on workers

- Frees skilled staff to focus on technical analysis, not repetitive tasks

Improved automation helps European companies remain competitive against low-cost refurbishment operations in other regions.

Quality, traceability, and consumer trust

Automated processes ensure consistent treatment of every device. Machine vision inspection, standardised workflows, and automated logging enhance:

- Diagnostic accuracy

- Cosmetic grading consistency

- Data erasure verification

- Quality assurance

This reliability is crucial for marketplaces and insurers that depend on predictable second-hand device quality.

Meeting rising demand in an expanding market

The secondary smartphone market has been growing rapidly, driven by sustainability values, lower consumer purchasing power, and shifting cultural attitudes toward refurbished devices. Automated solutions are essential for scaling operations to match this demand.

Enhancing technological resilience in Europe

Refurbished devices reduce reliance on imported new technology, increase device availability during supply chain disruptions, and support the EU’s broader digital sovereignty goals.

Wisematic’s biggest successes and biggest hurdles

Drawing on more than twenty years of experience in flexible automation, Wisematic has developed solutions uniquely suited to the complexities of refurbishment.

Success: Automating the hardest phase – preconditioning

Wisematic’s core breakthrough has been in automating the beginning of the refurbishment pipeline, where human operators historically faced the most monotonic, time-consuming tasks. Wisematic’s automation solutions now support:

- Automated device identification

- Adaptive machine vision inspection

- Automated plugging and connection

- Charging initiation

- Data erasure workflows

- Diagnostic launching and monitoring

- Automated sorting and labelling

- Intelligent routing to appropriate downstream processes

These systems combine advanced robotics, machine vision, and AI to manage device variability while maintaining strict process reliability.

Success: A track record of solving ‘impossible’ automation cases

Wisematic originally built its reputation by accepting—and successfully completing—highly specialised automation challenges that many other integrators declined. Early work in miniature part handling, medical device assembly, chip flipping, and other delicate processes created the foundation needed to tackle the uncertainty of used smartphones. This expertise allowed Wisematic to transition into the refurbishing industry at a time when no fully automated solutions existed.

Success: Future-proof modular system design

Wisematic’s SOLU™ RF series is designed to scale and evolve with device trends. By focusing on modularity, adaptability, and system reconfiguration, Wisematic ensures that refurbishers can expand capacity, integrate new device types, and adapt workflows without replacing core infrastructure.

Hurdle: Extreme variation and continuous market evolution

Even with sophisticated robotics and AI, device variability remains a central challenge. Each newly released device introduces fresh mechanical, electrical, and software considerations. Designing automation that remains robust in the face of constant technological change requires continuous R&D and iterative refinement.

Hurdle: Lack of standardisation across manufacturers

Without harmonised interfaces, connectors, and firmware-level reset protocols, automation must accommodate a broad spectrum of bespoke requirements. This increases engineering complexity, lengthens integration time, and raises cost for refurbishers.

Hurdle: Increasing mechanical complexity of devices

As foldables and multistage devices enter the mainstream, automation systems must evolve to handle dynamic, shape-changing hardware. Grippers, sensors, and vision systems must advance further to guarantee gentle, precise handling.

Standardising charging interfaces

The EU’s adoption of USB-C as a unified charging interface for many personal electronics demonstrates how regulatory action can reduce technical variation. This decision makes automation more feasible by standardising one of the most common and mechanically sensitive tasks in refurbishment. USB-C, as a unified charging interface for many personal electronics, demonstrates how regulatory action can reduce technical variation. This decision makes automation more feasible by standardising one of the most common and mechanically sensitive tasks in refurbishment.

Diagnostic and health check standardisation

Minimal common standards for device health reporting—battery condition, display status, sensor outputs—would streamline diagnostics and reduce the number of custom workflows required in automated lines.

Wisematic’s hopes for the future

Looking ahead, Wisematic envisions a future where refurbishment automation becomes deeply integrated into Europe’s circular economy infrastructure. Several key themes shape this vision.

Continued evolution of flexible automation technologies

Wisematic aims to further advance machine vision, AI-driven decision making, and adaptive robotic manipulation to handle increasingly complex devices, including foldables and emerging form factors.

Closer collaboration between industry and regulators

To fully unlock automated refurbishment potential, Wisematic hopes to see more structured collaboration between:

- European policymakers

- Device manufacturers

- Refurbishers

- Automation providers

Such collaboration would accelerate standardisation and reduce unnecessary complexity in device processing.

End-to-end automation from intake to final grading

While early-stage automation has accelerated significantly, Wisematic sees opportunities across the entire refurbishment pipeline—from automated unpacking to cosmetic grading, testing, and packaging.

A circular electronics economy powered by automation

Wisematic’s long-term aspiration is a refurbishment ecosystem where automation ensures:

- Minimal waste

- Faster device recirculation

- Improved profitability

- Higher-quality second-life devices

- Reduced environmental impact

This future aligns with EU climate targets and supports the growing societal expectation for sustainable consumption.

Conclusion

Smart device refurbishment is an essential pillar of Europe’s circular economy, supporting both environmental sustainability and digital resilience. Yet the complexity of the refurbishment process demands advanced, flexible, and intelligent automation systems capable of adapting to an ever-changing landscape of devices and conditions.

Wisematic has demonstrated that even the most challenging parts of refurbishment—such as preconditioning—can be automated through a combination of robotics, machine vision, AI, and modular system design. The company’s two decades of experience in tackling delicate and variable automation challenges place it at the forefront of this emerging field.

However, technological innovation alone cannot solve all industry challenges. Wide harmonisation of charging interfaces, packaging standards, diagnostic interfaces, and factory reset protocols will be essential to enable fully scalable automation and maximise the environmental and economic benefits of device reuse.

With ongoing innovation, strong collaboration, and supportive regulatory frameworks, Europe can lead the world in sustainable device lifecycle management—and automation will be the key enabler of that future.

Please Note: This is a Commercial Profile

This work is licensed under Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International.

Please note, this article will also appear in the 25th edition of our quarterly publication.