Ellie Gabel discusses the benefits, challenges, and future potential of circular aluminium in driving a sustainable economy and reducing reliance on plastics.

Aluminium has earned a reputation for being one of the most eco-friendly materials on the planet.

It is highly recyclable and is one of the most accessible, given the existing infrastructure. While its rates are impressive, many industrial professionals question whether it is enough to combat a plastic-dominated world.

What are the facts and figures around circular aluminium, and are they enough to convince industrial stakeholders to transition?

The benefits of aluminium

The biggest draw to aluminium is its infinite recyclability, aligning it perfectly with circular economic principles. It does not lose its properties, even after disassembly and remanipulation.

Other materials lack these characteristics, including plastic. Many factors prevent plastic from becoming the ideal recyclable, including progressive degradation, production of microplastics, durability losses, and formulation variances that prevent it from being 100% recyclable.

Producing virgin aluminium requires high temperatures, but remanufacturing recycled alternatives only requires 5% of the power. The drastic reduction could cut the emissions of related industries, lowering carbon dioxide emissions to help achieve global climate goals.

Finally, aluminium has some of the most prevalent recycling infrastructure on the planet. While the circular economy could embrace other sustainable or renewable technologies, the facilities necessary to process collected resources are minimal.

Leveraging what societies already have is essential for easing the transition to sustainable energy and material consumption.

The current aluminium economy

Aluminium metal values shift based on several factors, including geography, availability and time of year.

For example, the Midwest US is seeing relatively stable numbers, with variances depending on the day and cash value. The market is critical to pay attention to, as accessibility directly impacts corporations’ willingness to use it as a primary resource.

Inexpensive, reliable supplies will mitigate the potential drawbacks that currently exist in the aluminium industry.

This includes average recycling rates. While aluminium is infinitely recyclable, the rates need to be higher — the global recycling efficiency rate has only reached 76%, despite its reputation.

Many usable materials still end up in landfills, diminishing the life cycle they could have had. Additionally, the pervasiveness of downcycling aluminium into lesser products can prevent companies from using the strong material for more intensive purposes.

The collection economy is another influence on aluminium’s circular success story. Many single-stream recycling efforts delegate responsibility to consumers, but capturing and sorting aluminium requires more intervention and disassembly, especially for complex items like electronics.

Failure to consider these complications renders many aluminium components useless or too expensive to handle.

Knowing aluminium’s shortcomings

Aluminium has other value chain hindrances that prevent it from becoming the planet’s default material. Bauxite mining has a controversial image because it is energy-intensive and destructive to ecosystems.

This association could delay some companies from adopting aluminium altogether because the embodied emissions are too significant. These values still translate to recycled aluminium, though its adverse impacts become less after it is used multiple times.

However, using the same aluminium repeatedly becomes hard to achieve, particularly with alloys. Their complexity requires specific equipment, which many recyclers need to acquire.

The processing methods for different products vary so drastically that it becomes a financing issue for organisations.

Advancing the circular economy with aluminium

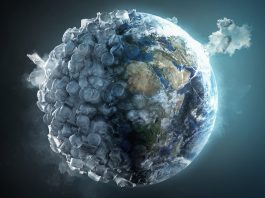

Society must combat the normalisation of plastic products, as waste is becoming one of the planet’s most difficult-to-control environmental concerns.

Around 15,000 plastic pieces enter waterways daily, with 46,000 total in every square mile of ocean. Despite the industrial and cultural deterrents to circular aluminium, there are ways to encourage gradual adoption:

- Boost collection rates: Use incentive programmes to encourage better extended producer responsibility from corporations and interest in citizens.

- Make sorting technologies more effective: Invest in research to enhance existing sorting equipment so it becomes more accurate and efficient.

- Design aluminium for recycling infrastructure: Convince manufacturers to design aluminium products in a way that is compatible with recycling machinery.

- Advocate for legislation: Lobby for more robust regulations, compliance and government funding to advance circular aluminium.

The efforts will culminate in sectors replacing non-eco-friendly materials with upcycled aluminium, but only if sustainable leaders advertise their knowledge.

For example, the automotive industry will only replace car bodies with circular aluminium if significant research demonstrates how it improves fuel economy.

Similarly, the construction sector will need to see life cycle assessments and proof that building facades last longer and maintain strength against corrosion.

Once the information spreads and awareness increases, it will increase the chances that more organisations will participate in activities that encourage advocacy and adoption.

The circular economy and its reliance on aluminium

Aluminium’s benefits are apparent, though the shortcomings prevent it from usurping plastic’s worldwide empire.

As nations and companies move toward circular economic practices, it will become more obvious why the world needs the supermaterial for a sustainable future.

Stakeholders must publicise aluminium’s advantages, particularly against the plastic economy, to normalise the transition and improve recycling rates, infrastructure, and adoption.