Norit discusses the current PFAS regulatory landscape, the scientific factors influencing PFAS adsorption on activated carbon, and how the company is demonstrating PFAS destruction at scale in its reactivation plant.

Per- and polyfluoroalkyl substances (PFAS) have emerged as one of the most pressing challenges to water quality in our time. These synthetic chemicals are extraordinarily persistent due to their carbon and fluorine bonds, earning them the name ‘forever chemicals’. Their widespread use in firefighting foams, textiles, electronics, food packaging, cosmetics and industrial applications has resulted in pervasive contamination of water sources across the globe. Scientific studies link PFAS exposure to cancer, immune dysfunction, elevated cholesterol, and other health impacts.

In response, regulators in both the US and the European Union are implementing increasingly strict limits on PFAS in drinking water, wastewater, and groundwater. Utilities, industries, and remediation projects face the dual challenge of complying with evolving standards while balancing costs and sustainability.

Activated carbon has proven to be one of the most effective and commercially viable tools for PFAS removal. Norit, with more than a century of leadership in activated carbon solutions, is at the forefront of advancing PFAS treatment strategies through granular activated carbon (GAC), powdered activated carbon (PAC), and thermal reactivation services. Operating an integrated network of facilities in the US and EU, Norit delivers technical expertise, proven removal performance, and sustainable pathways for long-term PFAS management.

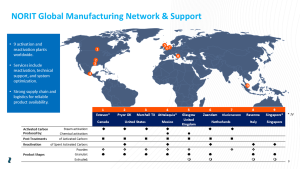

A map highlighting Norit’s US and EU facilities and the integrated supply chain that supports sustainable, full-cycle PFAS treatment

This article outlines the current PFAS regulatory landscape, the scientific factors influencing PFAS adsorption on activated carbon, and Norit’s demonstration of PFAS destruction at scale in its reactivation plant. Together, these activities illustrate Norit’s commitment to providing reliable and sustainable solutions on both sides of the Atlantic.

Regulatory drivers: US and EU perspectives

US regulations

The U.S. Environmental Protection Agency (EPA) finalised its National Primary Drinking Water Regulation (NPDWR) for PFAS in 2024. Legally enforceable maximum contaminant levels (MCLs) were set at 4 ng/L (ng/L is equivalent to PPT) for PFOA and PFOS, with 10 ng/L standards for PFHxS, PFNA, and GenX (HFPO-DA). For mixtures of multiple PFAS, a hazard index calculation provides additional compliance triggers.

Beyond federal rules, many US states have adopted even stricter thresholds. To assist with implementation, the EPA has provided $1bn in funding to support testing and treatment at public water systems and private wells. These requirements are accelerating adoption of GAC and reactivation services as the preferred treatment strategies for utilities nationwide.

European regulations

The European Union has adopted a group-based approach. Regulations require that the sum of all PFAS does not exceed 500 ng/L, while a subset of 20 targeted PFAS (PFAS-20, including common PFCAs and PFSAs) must remain below 100 ng/L. By 2026, enforcement of these thresholds will tighten further. Member States such as Denmark, Sweden, and Germany have enacted even stricter local limits, in some cases requiring levels as low as 2-4 ng/L for certain PFAS. The Netherlands RIVM has proposed 4,4 ng/L in toxicity equivalents. Compounding the challenge, the EU has mandated that all wastewater treatment facilities serving 150,000 population equivalents or more must install a “quaternary treatment” for micropollutants, including PFAS, by 2045. This will drive demand for cost-effective, reactivatable sorbents like GAC.

Together, these regulatory frameworks demonstrate a global convergence: PFAS must be removed to trace levels, and utilities require proven, sustainable solutions.

Scientific foundations: How activated carbon removes PFAS

activated carbon

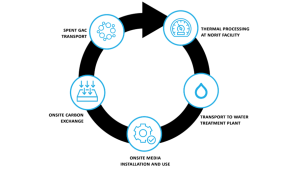

A circular diagram showing Norit’s closed-loop process for capturing PFAS, monitoring performance, treating water, thermally reactivating spent carbon, and returning it to service

Norit’s research teams in Europe and the US have extensively studied the factors that influence PFAS adsorption on activated carbon. Three sets of variables are critical:

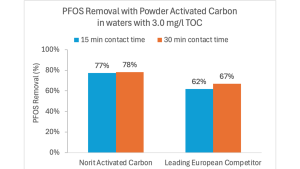

- PFAS properties where chain length and functional group(s) strongly dictate adsorption behaviour. Long-chain PFAS, such as PFOS and PFOA, exhibit higher hydrophobicity, making them more readily adsorbed onto the surface of activated carbons. Short-chain PFAS, like PFBA and GenX, are more soluble and mobile, posing greater removal challenges. Functional groups (carboxylate vs. sulfonate) influence both charge and hydrophobic interactions.

- Activated carbon properties for effective PFAS removal include optimised mesoporosity (>2 nm pores), hydrophobic surface chemistry, controlled particle size and positively charged surfaces that enhance electrostatic attraction with the negatively charged PFAS species. This electrostatic interaction plays a more crucial role for less hydrophobic PFAS species (i.e., short-chain PFAS, such as PFBA and PFBS). Norit’s GAC products are manufactured to deliver this balance of pore structure and surface chemistry.

- Water matrix effects where natural organic matter and competing anions can reduce adsorption efficiency. Jar testing with humic and fulvic acids confirms that organic co-contaminants compete with PFAS for adsorption sites. Testing under realistic conditions is therefore essential to predict field performance.

These findings confirm that no ‘one size fits all’ carbon exists. Instead, PFAS treatment requires careful matching of carbon properties to source water conditions, coupled with ongoing monitoring of breakthrough and capacity. Therefore, Norit offers in-house capabilities to assess the effectiveness of PFAS removal from real-world water samples, ranging from waterworks to industrial effluents. By simulating unique conditions in our lab, we can identify within a short time frame the right carbon solution that is needed for your requirements.

Norit Solutions: GAC, PAC, and reactivation

Granular activated carbon (GAC)

Norit’s GAC products are engineered for consistent performance across a range of PFAS challenges. Optimised pore structures maximise contact with PFAS molecules, while ultra-refined formulations minimise risks such as arsenic leaching. Comparative pilot studies show Norit’s carbons achieve breakthrough curves equivalent to or better than that of leading competitors, especially at higher organic content, with superior adsorption kinetics and capacities.

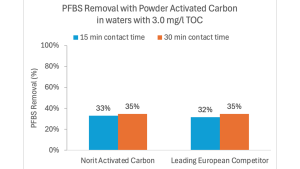

Powdered activated carbon (PAC)

PAC offers rapid response for short-term or seasonal PFAS contamination events. Its fine particle size allows fast adsorption kinetics, making it well suited for batch treatments or as a polishing step alongside coagulation and filtration. While PAC is not typically used for continuous municipal treatment, it provides flexibility where GAC may be impractical.

Thermal reactivation

Perhaps the most impactful solution lies in reactivation, which facilitates the destruction of PFAS, thereby decomposing the so-called ‘forever chemicals’. PFAS-laden spent GAC is thermally treated under reducing environment, releasing and decomposing adsorbed contaminants. The (partially) decomposed released products are successively further destroyed under oxidising conditions in afterburners and neutralised by caustic scrubbers. Reactivation restores PFAS adsorption capacity comparable to virgin GAC, reduces lifecycle costs by 20–40%, and minimises landfill disposal. This closed-loop approach drives the circular economy, representing the most sustainable long-term pathway for PFAS sorbent management.

Reactivation demonstration: Norit facility PFAS reactivation trial

To validate PFAS destruction in full-scale practice, Norit conducted a landmark reactivation trial at its Pryor, Oklahoma facility. Using 71,000 kg of PFAS-laden spent activated carbon sourced from a municipal water system, the trial tracked PFAS mass flows across solids, liquids, and gases.

Key outcomes included:

- Destruction efficiency: Overall PFAS conversion of 99.98%, with non-detect levels in reactivated GAC and PAC products.

- Process performance: Rotary kiln residence times of >3 hours at elevated temperatures, followed by afterburner combustion, ensured near-complete PFAS breakdown.

- Environmental safeguards: Scrubber blowdown water was polished with GAC to achieve a 1,000-fold PFAS reduction before discharge. PFAS concentrations in the surrounding environment were measured both before and during the trial, showing no significant change and indicating no occupational health risks. Ambient air monitoring showed PFAS levels well below occupational exposure thresholds and did not see a difference in these concentrations during the trial.

- Carbon quality: Reactivated carbon matches virgin carbon in iodine number and BET surface area, pore volume, and PFAS adsorption performance, as confirmed through rapid small-scale column testing.

These results demonstrate that reactivation not only destroys PFAS effectively but also returns carbon to service with no performance compromise of a true circular economy model.

Research and regulations

In parallel, Norit’s R&D teams are deeply engaged in PFAS adsorption science and regulatory alignment. Key initiatives include:

- Literature review and experimental design: Detailed evaluations of PFAS adsorption mechanisms have guided development of test protocols that incorporate realistic water matrices, short- and long-chain PFAS, and natural organic matter.

- Regulatory readiness: With the EU preparing for stricter PFAS limits, Norit is working closely with water utilities and regulators to validate GAC performance under new standards. Particular focus is placed on short-chain PFAS removal, given their prevalence in European surface waters.

- Pilot testing: Trials with different carbons, including modified surface chemistries, are underway to optimise performance against EU-regulated PFAS-20 molecules.

- Knowledge dissemination: Findings are shared through scientific publications and participation in both European and US water conferences, helping utilities design treatment strategies that meet national and EU-wide requirements.

By integrating bench-scale research with real-world applications, Norit positions itself as a trusted partner for utilities preparing for upcoming enforcement deadlines.

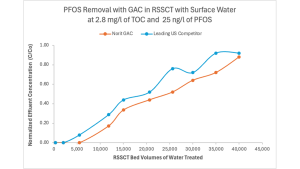

A breakthrough study showing normalised PFOS effluent concentrations (C/Co) over increasing bed

volumes of surface water treated. Norit GAC delivers slower breakthrough and sustained lower C/Co values

across the full test range, indicating stronger adsorption performance and longer PFOS removal capacity

than the competing GAC

Sustainability and the circular economy

PFAS treatment is not only a technical challenge but also a sustainability imperative. Without reactivation, spent carbons must often be landfilled or incinerated, which is both costly and environmentally burdensome. Norit’s closed-loop approach reduces greenhouse gas emissions, cuts waste and lowers total cost of ownership for utilities.

The reactivation trial demonstrated that reactivation achieves 99.99% PFAS destruction while restoring carbon adsorption capacity. This model is being extended across Norit’s European reactivation facilities, ensuring that both US and EU customers can benefit from a consistent, sustainable solution.

Conclusion

As PFAS regulations tighten across the globe, utilities and industries require treatment strategies that combine technical efficacy with economic and environmental sustainability. Activated carbon, whether in granular, powdered, or reactivated form, remains the most proven and scalable solution.

Norit’s activities in both the US and EU demonstrate leadership across the full PFAS treatment lifecycle. Rigorous scientific research, high-performance carbon products, and validated destruction through reactivation offer a comprehensive approach to managing PFAS contamination.

With facilities and expertise spanning two continents, Norit is uniquely positioned to help customers navigate regulatory requirements, implement cost-effective treatment, and advance toward a sustainable, circular future.

Authors

Regina Rodriguez, PhD, Jantien Foekema, PhD, Matthijs van der Ham, PhD, Brandon Hamilton, Rob De Jonge, Benjamin Pepper.