Travis Miller, Chief Strategy Officer and General Counsel at Source Intelligence, discusses AI-powered full material declarations (FMDs) and their potential in PFAS detection and elimination.

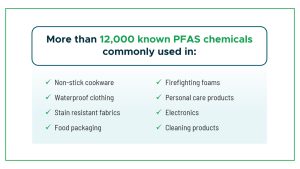

The global regulatory landscape is undergoing a seismic shift. From the U.S. Environmental Protection Agency (EPA) to the European Chemicals Agency (ECHA), governments are accelerating efforts to eliminate hazardous substances from consumer and industrial products. At the centre of this movement are per- and polyfluoroalkyl substances (PFAS) – a class of over 12,000 synthetic chemicals known for their persistence in the environment and potential harm to human health.

The compliance crossroads

For companies that manufacture, import, or distribute products, supply chain compliance has become a strategic imperative. The growing legal liability associated with environmental product compliance (particularly around PFAS) has reached unprecedented levels. Tens of billions of dollars in litigation settlements have been awarded, and many more cases are anticipated. In a landmark move, three of the world’s largest producers of PFAS-related materials have voluntarily chosen to sunset and obsolete their production lines. This has created a business continuity crisis. Companies that fail to illuminate their sub-tier supply chains and proactively manage chemical risk are gambling with their future.

PFAS: The forever chemicals at the centre of expanding global regulations

PFAS are used in everything from non-stick cookware to aerospace components. Their chemical stability makes them useful, but also dangerous. They accumulate in living things and do not break down easily, earning the nickname ‘forever chemicals’.

Regulatory bodies are responding with increasing urgency. The EPA’s TSCA 8(a)(7) rule mandates extensive PFAS reporting, while Maine’s PFAS ban requires manufacturers to disclose PFAS use or face market exclusion. The OECD, POPs, and EU REACH frameworks continue to expand their PFAS lists, creating an extensive patchwork of global obligations that companies must navigate.

The volume of covered chemicals is staggering. The EPA currently lists over 12,000 PFAS substances. The OECD adds more than 4,700. The challenge is not just identifying PFAS in products; it is also identifying them across a global, multi-tiered supply chain where visibility is often limited or non-existent.

The sub-tier supply chain blind spot

Most companies have visibility into their Tier 1 suppliers (parties they directly purchase goods and materials from). However, PFAS risks often reside deeper, buried in Tier 2, Tier 3, and beyond (called the ‘nth tier’). Without full transparency, compliance becomes a game of risk-laden guesswork. Financially, non-compliance can result in fines, recalls, and lost revenue. Reputationally, consumers and investors are increasingly intolerant of hazardous chemical risks. Operationally, incomplete data can delay product launches, disrupt supply chains, and erode trust with key stakeholders. The inability to see beyond Tier 1 is a material risk that can undermine entire product lines or market strategies. Moreover, this same risk has been compounded by additional regulatory demands from the UFLPA (forced labour bans), EUBD (minerals traceability), and the digital product passport requirements.

Case study: Acme Inc. and the hidden PFAS risk

Consider Acme Inc. is a mid-sized manufacturer of precision medical devices. One of its flagship products, a compact infusion pump used in hospitals worldwide, was recently flagged during a routine supply chain due diligence review. The issue? A seemingly insignificant O-ring used in the pump’s internal valve system was found to contain PFAS.

The O-ring, sourced from a Tier 3 supplier, had never been flagged in previous compliance checks because the supplier had only provided a general certificate of compliance. It wasn’t until Acme began collecting full material declarations (FMDs) that the presence of PFAS was uncovered by leveraging AI evaluations to look at every chemical and each CAS number, then comparing them against the tens of thousands of regulated PFAS.

The implications were immediate and severe. The O-ring was a critical component, and switching to a new material or vendor would require full revalidation of the device, a process that would take 12 to 18 months and cost millions. Worse, the supplier had already announced plans to phase out the PFAS-containing material due to regulatory pressure.

For Acme’s procurement team, this meant scrambling to make a last-time buy and find alternative sources. For legal and risk leaders, it raised concerns about liability and market access. And for engineering, it triggered a redesign and requalification effort that diverted essential resources from innovation. All of this was caused by a standard material in an O-ring and a lack of technology-based controls that could have been avoided with earlier access to AI-evolved FMDs.

AI-powered full material declarations: The foundation of modern supply chain risk management and compliance

FMDs provide a complete chemical breakdown of a product, down to the homogenous material level. They include substance names, CAS numbers, and concentration levels, and are delivered in formats ranging from PDFs to IPC-1752A XML files. They are also structured files that provide excellent grounding for modern large language models that can leverage and compare the databases against regulated substance lists.

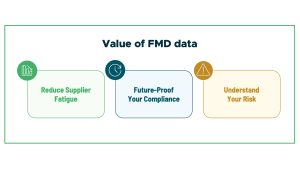

Unlike certificates of compliance or safety data sheets, FMDs are not limited to specific regulations. They are regulation-agnostic, making them a future-proof asset. With an FMD, companies can identify PFAS at the substance level, map risks across the entire bill of materials (BOM), and respond quickly to new regulatory requirements without having to re-engage suppliers repeatedly.

FMDs are not just a better document; they are a better strategy. They enable proactive compliance, reduce supplier fatigue, and provide data foundations for broader ESG and sustainability initiatives. In a world where regulatory agility is a competitive advantage, FMDs are the infrastructure that enables it. Moreover, when combined with AI analysis, they open a new world of data-driven insights.

Automation and AI: Scaling the FMD strategy

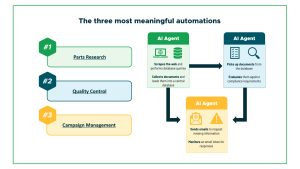

Manual compliance processes are no longer sustainable. Regulatory velocity has outpaced human capacity. To deal with this reality, Source Intelligence has invested in AI-powered agentic workflows that automate the most time-consuming aspects of compliance.

These intelligent systems scrape the web and internal databases for parts data, collect and validate supplier documents, map substances to EPA and OECD PFAS lists, and generate compliance reports automatically. The result is a scalable, efficient, and accurate compliance infrastructure that reduces supplier friction and accelerates time-to-insight. Without AI, the acquisition and mapping against millions of sub-tier entities to tens of thousands of PFAS chemicals is all but impossible.

This approach is not just about operational efficiency – it’s about insightful resilience. As one compliance executive recently put it: “We literally wouldn’t be able to ship without AI. The ability to scale compliance operations without scaling headcount is a necessity. However, the ability to identify supply chain shortages and acquire critical components and materials before our competitors are aware is a strategic advantage.”

Being practical and pragmatic with AI investments

According to Massachusetts Institute of Technology (MIT), 95% of corporate AI projects failed to produce any ROI between 2024 and 2025. That is a staggering amount of failure from a business investment standpoint. It also triggers the obvious question: Why?

To answer this question, we interviewed 136 customers and held seven roundtable sessions in 2025, which revealed three key insights and shaped Source Intelligence’s AI strategy.

- Generative AI has proven incredibly effective in individual efficiency, but corporate operational gains have lagged. This is because most AI-powered applications to date are prompt-driven and interactive with a user, whereas systems and agentic workflows have not been appropriately designed to integrate human problem-solving into the loop of the systems. The result is heavy integration that is not adaptive enough to address highly variable requests for insight, which then defaults to staff, reducing the potential efficiency gains AI automation promises.

- Corporations are reluctant to grant third-party large language models access to trade secrets and sensitive information. Generative AI is extraordinarily good at analysing large data sets. However, it is perceived as absorbing and taking ownership of all the information it ingests. Corporations and multinationals are justifiably very concerned about the prospects of an integrated AI agent taking, disseminating, or claiming ownership over critical business intelligence and/or intellectual property. Laws and norms are lagging innovation, which is stunting adoption.

- The Generative AI hype has been focused on eliminating the roles of humans and enabling revenue-generating activities. Cognitively, many employees are hesitant to train AI to replace their role. It is also the case that people buy products and services from other people and experience unease with a purely robotic interface for anything beyond nominal purchases. The result is an adoption issue and investments that are failing to produce justifiable returns.

Picking up nickels adds up to real dollars

To incorporate these learnings, Source Intelligence’s AI strategy has been laser-focused on data protection and automating arduous processes that people dislike and/or routinely fail to perform adequately. In this context, we perceive supplier engagement to be the highest value investment for AI-generated return on investment.

The lowest hanging fruit has been accessing the tens of millions of FMDs that are publicly available online. Businesses have been gathering and publishing substance and materials information since the European Union passed the Restriction of Hazardous Substances (RoHS) in 2006. The practice of sending annual campaign emails to suppliers requesting this information has not changed in 20 years.

Every email request for information that is already publicly available places added costs on both the requester and the requestee. Theoretically, this transaction cost should be borne by each component purchase to be compliant with restricted substance and chemical disclosure laws. However, that has not been the case due to costs and resource constraints, meaning a large volume of transacted goods, components, and raw materials is non-compliant and should be ineligible for import into regulated markets.

The result is increased risk of detainments, delays, and fines, and an undue cost burden being placed on suppliers that they did not contract for and are often unprepared to absorb. The solution to this plethora of challenges comes in the form of multi-agent, agentic workflows.

Agentic workflows are an autonomous AI system that can independently make decisions and take actions to achieve a pre-defined goal, with minimal human oversight. However, the complexity and dynamism of the workflow can result in errors or unpredictable results. A multi-agent system solves this issue by assigning individual agents to discrete, repeatable tasks that can be monitored and interpreted by both other agents and human oversight.

The result is systematic cascading supply chain queries that can be pushed to an army of domain-specific agents to autonomously return needed information that is already published. Once returned, the Source Intelligence’s C-Map instance interprets and infers compliance risks from the full material declarations and other acquired data, creating an ask-once, service-many request management relationship.

Supplier enablement, not supplier fatigue

Suppliers are essential partners in the compliance journey and our business operations. However, we have collectively overwhelmed them with redundant requests, clunky portals, and inconsistent expectations. FMDs offer a better path.

By collecting comprehensive data once and using it across multiple compliance programmes, companies can reduce the burden on suppliers while improving data quality. This approach fosters collaboration, builds trust, and ensures that suppliers remain engaged rather than alienated.

When suppliers are empowered, everyone wins. Compliance becomes more accurate, more efficient, and more sustainable. And in a world where supplier relationships are increasingly strategic, this kind of enablement is a differentiator.

Expanding on the strategic value of FMDs

FMDs are not just a compliance tool. They are a strategic asset that supports a wide range of business objectives. From global trade programme management, ESG reporting and obsolescence to circular economy initiatives and product innovation, FMDs provide the data backbone for modern supply chain risk management strategy.

Companies that invest in FMDs gain a competitive edge. They enter markets faster, respond to regulatory changes more effectively, avoid supply chain shocks, while building trust with customers, investors, and regulators alike. In a world where transparency is currency, AI-powered FMD analysis is the gold standard.

Conclusion: The FMD mandate

The regulatory clock is ticking – PFAS is just the beginning. The future of compliance is mandatory full disclosure. AI-powered full material declarations are the only scalable, sustainable, and strategic way to illuminate the sub-tier supply chain, identify and eliminate PFAS, and future-proof compliance programmes.

At Source Intelligence, we believe that technology-empowered transparency is essential for mitigation and strategic business forecasting. AI-empowered FMDs are the key to unlocking the business value that is currently buried in sub-tier supply chains.

About the author

Travis Miller is the Chief Strategy Officer and General Counsel at Source Intelligence. He leads the company’s strategic initiatives in regulatory compliance, supply chain transparency, and ESG innovation.