Finland’s clean hydrogen revolution is gaining speed in Oulu, powered by cutting-edge research programme H2FUTURE at the University of Oulu.

Finland is rapidly establishing itself as a location for clean hydrogen development, with the northern city of Oulu at the forefront of this green revolution. In 2025, the City of Oulu and French firm Verso Energy signed an agreement to build Finland’s largest hydrogen refining plant – a €1.4bn facility producing 80,000 tonnes of sustainable aviation fuel (SAF) annually and creating 250 jobs. This project will make Oulu a key hydrogen hub in the Nordics, showcasing how regional cooperation can attract major Power-to-X (PtX) investments.

German company Hy2gen has likewise secured a site at Oulu’s Vihreäsaari Port for a 200 MW renewable hydrogen and e-fuels plant, positioning Oulu to become the Baltic Sea region’s leading centre for PtX projects. In fact, Oulu now hosts more synthetic fuel initiatives under development than any other city in the region, with multiple companies (Verso, Hy2gen, Energiequelle, ABO, P2X Solutions, Oulun Energia) planning hydrogen-based facilities. This momentum is fueled by Oulu’s favourable conditions – abundant low-cost renewable energy, strong research infrastructure, and excellent logistics – which together create an ideal environment for a thriving hydrogen economy.

Crucially, Oulu is leveraging national and international networks to amplify its hydrogen ambitions. It plays a prominent role in BotH₂nia, an international alliance building a large-scale hydrogen economy around the Gulf of Bothnia and Baltic Sea. Oulu’s active participation in the BotH₂nia network exemplifies the region’s collaborative ethos – the city hosts the Nordic Hydrogen Week and Northern Power forum to convene industry leaders, researchers, and policymakers on advancing hydrogen solutions. These efforts underscore Finland’s commitment to action over words, translating visionary plans into tangible projects. With supportive policies (such as streamlined zoning and permitting) and public-private cooperation, Finland is emerging as a global hub for green hydrogen innovation – and Oulu’s rapid progress shows how a mid-sized Arctic city can punch above its weight in the clean energy transition.

University of Oulu: A hydrogen research powerhouse

At the heart of Oulu’s hydrogen ecosystem is the University of Oulu, which has become one of Northern Europe’s key research hubs for hydrogen and green transition technologies. The university coordinates over 60 hydrogen-related projects with total funding exceeding €64m, covering the entire hydrogen value chain from production and storage to utilisation, materials, circular economy, education and societal aspects of the transition. This comprehensive portfolio – backed by state-of-the-art research infrastructure and an open, collaborative culture – uniquely positions Oulu to shape the future of sustainable energy in the Arctic and beyond.

Beyond research: The University of Oulu is equally committed to hydrogen education and workforce development

Beyond research, the University of Oulu is also dedicated to advancing hydrogen-related education and developing the future workforce. Through initiatives like the FITech Hydrogen study module and the H2School project, the university and its partners are training the next generation in hydrogen technologies – from fundamentals of the hydrogen economy and fuel cells to hydrogen safety and industrial applications. New hydrogen-focused courses have been integrated into engineering curricula (e.g. Hydrogen and Fuel Cells, Hydrogen as a Source of Flexibility), reflecting a holistic approach that spans undergraduate, graduate, and continuing education. By embedding hydrogen across disciplines, the university ensures a pipeline of skilled experts ready to drive the green transition.

Crucially, the University of Oulu also spearheaded the creation of Hydrogen Research Forum Finland (often referred to as Hydrogen Research Finland), a national platform uniting Finnish universities and institutes to coordinate hydrogen R&D efforts. This forum facilitates knowledge-sharing and joint projects across institutions, amplifying Finland’s impact on the global hydrogen stage. Multidisciplinary and international cooperation is central to Oulu’s philosophy – for example, the university’s H2FUTURE team represented Finland at the World Hydrogen Summit 2024 in Rotterdam, showcasing Oulu as a dynamic hydrogen hub and forging new connections with industry and academia worldwide. Such engagements ensure that Oulu’s innovations contribute to and benefit from the broader hydrogen community.

Inside the H2FUTURE Programme: Clean hydrogen and sustainable steel

The capstone of Oulu’s hydrogen initiatives is the H2FUTURE programme – a five-year (2023–2028) research effort funded by the Research Council of Finland’s PROFI7 scheme. Short for “Hydrogen Future as a Climate Change Solution,” H2FUTURE aims to develop breakthrough solutions for clean hydrogen production and fossil-free steelmaking. This transdisciplinary programme unites chemists, physicists, materials scientists, and engineers under a single umbrella to address hydrogen challenges holistically, from generation to end-use. H2FUTURE’s research portfolio is organised into four interconnected themes.

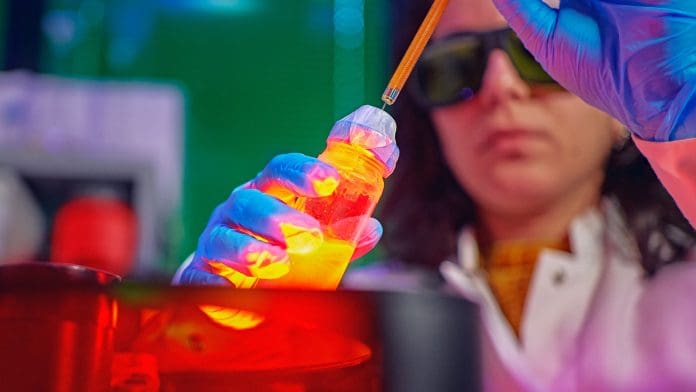

Solar hydrogen – Developing direct solar-driven water splitting technologies

Researchers in this theme are designing advanced photocatalysts (e.g. novel bismuth halide perovskites) to maximise sunlight absorption and boost hydrogen output without consuming electricity. Led by Professor Marko Huttula (H2FUTURE Programme Lead) and tenure-track Professor Matti Silveri, this team even explores quantum computing algorithms to better model photo-catalytic materials at the molecular level. By leveraging next-generation computation, Silveri’s group aims to optimise catalyst designs and chemical processes for hydrogen production — a cutting-edge approach linking quantum technology to sustainable energy.

Direct solar hydrogen technology has recently reached a crucial point, enabling the founding of the world‑class spin‑off company ZUN‑H Oy, which commercialises technology developed at the University of Oulu.

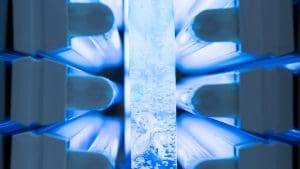

Carbon-emission-free H₂ – Scaling up methane pyrolysis and other CO₂-free hydrogen production methods

This theme focuses on catalytic processes that split methane (natural gas or biogas) into hydrogen and solid carbon without releasing CO₂. Under Professor Ulla Lassi, an expert in sustainable chemistry, and Associate Professor Satu Ojala, the team is engineering robust catalysts and reactors to make methane pyrolysis energy efficient.

The solid carbon byproduct can be high-value (e.g. battery-grade nanocarbon), turning a side-stream into an asset. “If even one of the major components in batteries becomes more sustainable to produce, then you will take a big step towards more sustainable energy in general,” said Professor Lassi.

A shining example of their impact is Hycamite TCD Technologies, a Finnish startup that built Europe’s largest methane-splitting pilot plant. Hycamite’s core technology – an emissions-free hydrogen production process – is rooted in long-term research done at the University of Oulu by Professor Lassi’s group.

H2FUTURE researchers joined the opening of Hycamite’s Kokkola plant in 2024, celebrating the transfer of lab discoveries into an industrial-scale solution.

“It’s great to see scientific research transformed into a new business,” said Lassi, noting that Hycamite’s founders are Oulu alumni and their innovation grew from university research and developed catalytic materials. This academia-to-industry success story illustrates H2FUTURE’s impact beyond papers – enabling real-world deployments of clean hydrogen tech.

Sustainable use of H₂ in metal production – Revolutionising metallurgical processes by replacing fossil fuels with hydrogen

This theme tackles one of the hardest-to-abate sectors: steel and ferroalloys production. Under Professor Timo Fabritius (Head of Process Metallurgy at Oulu) and Professor Pasquale Cavaliere, researchers are advancing techniques to reduce metal oxides with hydrogen instead of carbon. By improving reaction kinetics and energy efficiency in processes like iron ore reduction, they aim to drastically cut CO₂ emissions generated in steelmaking.

“Reducing the carbon footprint of steel production depends critically on replacing carbon-based reduction agents with hydrogen as carbon-dioxide-free technology”, said Professor Fabritius, vice leader of the H2FUTURE programme.

Cavaliere, a renowned metallurgist recruited to Oulu, emphasised hydrogen’s versatility in decarbonising industry: “Hydrogen can be employed in so many applications that it will be a crucial actor for a sustainable future.” His team is optimising hydrogen-driven reduction in shaft furnaces and novel methods (such as hydrogen plasma or fluidised bed reactors), working toward fossil-free steel production. This aligns with initiatives like Hybrit in Sweden, which aims for completely fossil-free steel by 2030. By developing hydrogen-based metallurgical processes now, H2FUTURE is helping pave the way for the steel industry’s green transition in Finland and across Europe.

Optimising ultra-high-strength steels – Ensuring next-generation metals can withstand hydrogen use

Hydrogen’s Achilles’ heel in metals is embrittlement: hydrogen atoms can infiltrate steel, causing cracks and failures. Under Professor Jukka Kömi and tenure-track Professor Vahid Javaheri (a physical metallurgist), this theme is devising steels and treatments that resist hydrogen’s damaging effects.

“When we are building a hydrogen-based society where hydrogen is widely used as a fuel or energy source, we really need to emphasise research on which materials can be used in such an environment,” noted Professor Kömi.

Dr Javaheri’s group employs advanced microscopy and atom-scale simulations to understand how hydrogen interacts with metal microstructures. Their research has achieved steels with nearly three times the strength of typical high-strength alloys (up to 2.5 GPa) while maintaining ductility. Such ultra-strong steels mean less material is needed for the same task, cutting the carbon footprint of construction.

Moreover, by tailoring microstructures and adding designed traps for hydrogen atoms, they are developing alloys that remain tough and reliable in hydrogen-rich environments. These breakthroughs are vital for building the infrastructure of the hydrogen economy – from pipelines and storage tanks to fuel cell vehicles – where steel must handle hydrogen safely. As Javaheri explained: “This work is essential for the safe and efficient use of hydrogen as an energy carrier and as a reducing agent in steelmaking,” contributing both to cleaner energy and greener steel production.

H2FUTURE´s transdisciplinary ecosystem bridges fundamental science and industrial application

Together, these four themes form a synergistic pipeline: H2FUTURE covers hydrogen production (solar and pyrolysis routes), through storage and transport (materials compatibility), to end-use in heavy industry (steelmaking). It’s a truly transdisciplinary ecosystem bridging fundamental science and industrial application. The programme’s structure also fosters cross-pollination: for instance, materials discoveries in the steel theme feed back into better catalysts, while insights from hydrogen production inform process engineers on optimum hydrogen quality for metallurgy. By uniting experts across physics, chemistry, and engineering, H2FUTURE is generating the kind of holistic innovation needed to solve complex sustainability challenges.

We are always interested in collaboration, so please get in touch with our active team!

Please Note: This is a Commercial Profile

This work is licensed under Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International.

Please note, this article will also appear in the 25th edition of our quarterly publication.