As governments tighten restrictions on forever chemicals, manufacturers across the globe are racing to find safer, high-performance alternatives.

One company, Nanize, is emerging as a frontrunner in this new era, advancing PFAS-free coatings that outperform many legacy non-stick technologies.

Powered by its cutting-edge polysilazane chemistry, Nanize is rapidly becoming a preferred partner for automotive, aerospace, electronics, medical, and consumer-goods manufacturers seeking next-generation surface protection.

A new standard for speed and efficiency

Nanize’s PFAS-free coatings introduce a breakthrough in production dynamics: an ultra-fast curing process.

The material fully sets in about a minute at temperatures below 100°C – dramatically faster and more energy-efficient than traditional high-heat curing methods.

For manufacturers under pressure to reduce emissions and streamline operations, this innovation represents a significant competitive advantage.

Superior non-stick performance without PFAS

Despite eliminating PFAS entirely, Nanize’s formulations deliver exceptional hydrophobic and oleophobic properties, resisting water, oils, and a wide range of contaminants.

The result is a durable, easy-clean surface ideal for environments where appearance and hygiene matter.

Public infrastructure developers are already turning to these coatings for enhanced anti-graffiti protection, preserving both aesthetics and long-term maintenance budgets.

From aerospace to everyday electronics

The versatility of Nanize’s PFAS-free coatings is accelerating adoption across multiple industries.

Aerospace and automotive engineers are applying the technology to wind turbine blades, exterior body panels, and other components that demand ultra-smooth, low-drag surfaces.

In the electronics sector, manufacturers are using the coatings to protect touchscreens, optical components, and solar modules from smudging and abrasion.

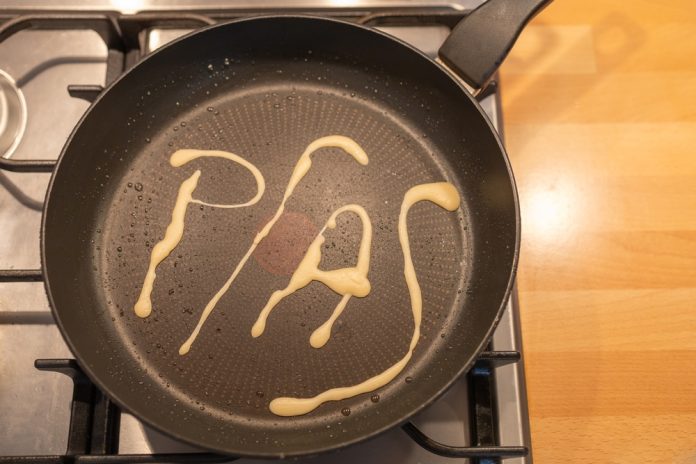

Medical device makers and cookware brands also benefit from long-lasting, bacteria-resistant finishes that support safer, healthier products.

Sustainable, scalable, and future-ready

Nanize’s focus on environmental responsibility ensures full compliance with emerging global regulations targeting PFAS compounds.

Beyond regulatory alignment, the technology reduces manufacturing waste and supports greener production practices – a key factor driving interest from sustainability-focused corporations.

The company’s polysilazane-based solutions also rival the durability found in space-grade coatings, offering ceramic-like performance previously associated with NASA’s mission-specific materials. Unlike those niche technologies, Nanize’s coatings are engineered for mass-market scalability, making high-end surface protection accessible to a broad range of manufacturers.

A safer future for non-stick technology

With strategic partnerships spanning major infrastructure, automotive, and consumer brands, Nanize is setting a new benchmark for PFAS-free coatings.

Its customisable formulations, low-friction durability, and proven environmental benefits position the company at the forefront of a global shift toward safer, more sustainable materials.

The transition away from PFAS has begun – and Nanize is defining what comes next.