Nanize patented technology creates durable, functional PFAS-free coatings that are fully cross-linked and covalently bound to the substrate in under one minute at temperatures below 70°C.

Nanize have developed patented coating and curing technology for hydrolysing polysilazanes containing functional nano-additives to create glass-like, fully cross-linked and covalently bound surfaces. Our PFAS-free solutions for a wide range of applications deliver unmatched durability, ultra-low friction, and sub-minute curing at temperatures below 70°C without catalysts.

Coatings without compromise proven by testing

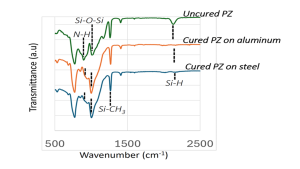

Having made over 20,000 individual tests, extensive lab validation of Nanize coatings has been undertaken, including by FTIR (Fourier-transform infrared spectroscopy), to verify polymer crosslinking, hard curing, durability and performance.

Test results confirm:

- Full curing in < 1 minute at temperatures below 70°C

- No catalyst required – minimising process complexity

- Dense crosslinked network confirmed by FTIR

- Proven covalent substrate bonding across a broad range of metals, plastics and glass

Nanize ultra-rapidly cured polysilazane coatings are proven to create hard, durable, glass-like and dense 3-dimensional Si-O-Si dominant cross-linked structures that are covalently bonded to the substrate.

Nanize: Coating problems cured

Nanize recognised that the excellent potential of polysilazane coatings has been constrained by the ability to achieve a high cross-linking density on curing. Typically, hydrolysis of the polysilazane that takes place during curing requires prolonged periods of many days at room temperature or shorter periods at temperatures above 250°C with a catalyst. Using FTIR analysis, the limited curing of polysilazane under these conditions can be readily identified, resulting in poor durability. In addition, curing at temperatures above 250°C restricts the choice of substrate material, ruling out plastics and electronic components, for example.

The patented technology developed by Nanize achieves near-perfect cross-linking and covalent bonding to the substrate through hydrolysis of polysilazanes in under 1 minute and below 70°C.

Complete curing in 30 seconds at 70°C is evidenced by FTIR spectrometry of Nanize polysilazane coatings applied by ultrasonic spray to stainless steel and aluminium.

Note the absence of Si-H and N-H on the cured samples, with a corresponding strong Si-O-Si.

A key feature of polysilazanes and one which differentiates them from other similar polymers is the ability to covalently bond nano-additives to the polymer backbone, which, upon curing, can confer specific coating performance characteristics such as super-hydrophobicity, operation at temperatures up to and above 1000°C, anti-microbial, corrosion resistance, etc.

Nanize have created and continues to develop a range of polysilazane formulations containing nano-additives which can be ultra-rapidly cured in less than one minute and below 70°C, which have specific enhanced coating performance characteristics.

Nanize. One technology. Multiple industries.

Nanize coatings are transforming surface protection across multiple sectors – enabling cleaner, safer, more efficient performance wherever advanced coatings are needed.

Cookware and bakeware

Manufacturers can benefit from a simplified and lower-cost manufacturing process thanks to Nanize ultra-rapid curing.

Problem: PFAS and other fluorine-containing compounds used in cookware and bakeware do not retain their non-stick properties, are prone to peeling off the surface and will be banned.

Solution: Nanize FDA-compliant coatings do not contain any PFAS or Fluorine. They covalently bond to the substrate and retain their excellent non-stick performance.

Result: Cookware and bakeware manufacturers can continue to meet their customers’ expectations through offering PFAS-free, high-performance, durable non-stick products coated and ultra-rapidly cured using Nanize polysilazane formulations and technology. In addition, manufacturers can benefit from a simplified and lower-cost manufacturing process thanks to Nanize ultra-rapid curing, which does not need protracted time at high temperatures.

Commercial and domestic

Creating smart surfaces for demanding environments.

Problem: Protective and decorative surfaces (TPU, paint, trim) suffer from chemical degradation, marking / graffiti, or abrasive wear.

Solution: Nanize polysilazane formulations can be customised to create coatings that meet specific end-user requirements and expectations. With Nanize ultra-rapid curing taking place below 70°C, durable polysilazane formulations and coatings can be applied to a wide variety of substrates, including plastics such as TPU film.

Result: Coatings can be readily high-volume manufactured cost-effectively to exhibit excellent non-marking, anti-graffiti, stay-clean properties which enhance their appearance, are easy to maintain and are durable.

Renewable energy

Reduces soiling on solar panels and turbine blades, increasing output and lowering cleaning costs.

Problem: The accumulation of soiling and dirt over time reduces energy generation on solar modules and reduces wind turbine performance through increased drag.

Solution: Nanize coatings have a high degree of hydrophobicity and an extremely low coefficient of friction that significantly reduces the build-up and adhesion of dirt on the surfaces to which they are applied.

Result: Through the use of Nanize polysilazane formulations and ultra-rapid curing process, renewable energy generation performance of solar modules and wind turbines can be improved with a corresponding reduction in the need for downtime to undertake cleaning. The durability and long-life of Nanize coatings is achieved through excellent cross-linking during the curing process, combined with covalent bonding to the substrate to prevent flaking and delamination in use.

Automotive

Protects exteriors, TPU wraps, and sensitive surfaces from wear, graffiti, and UV — with non-marking, self-cleaning coatings.

Problem: Exterior plastics used within the automotive sector, ranging from headlamp covers to providing protection for sensors such as LIDAR and cameras, suffer from abrasion/scratching and impaired functionality from water and dirt build-up.

Solution: Nanize’s hydrophobic coatings, which are hard, durable, and scratch-resistant, can be readily applied using standard industry processes and then ultra-fast, fully cured in less than one minute and below 70°C without damage to the performance of the plastic substrate.

Result: The performance and durability of complex moulded exterior plastic parts used within the automotive sector can be significantly enhanced through a combination of Nanize polysilazane coating formulations and Nanize ultra-rapid curing technology. The production process for applying the coatings and curing them can be readily introduced into a high-volume manufacturing environment, thanks to the low temperature and speed of the process.

Electronics & displays

Enables anti-smudge, anti-static, and easy-clean surfaces with sub-100°C curing for thermally sensitive substrates.

Problem: Touch screens and displays attract fingerprints and dust, which impairs their use and, in common with other electronic devices, cannot tolerate elevated temperatures during manufacturing, such as OLEDs.

Solution: Nanize functional coatings can be quickly and effectively applied and ultra-rapidly, fully cured at temperatures below 70°C to create durable, low-friction, smudge-repellent protective surfaces with excellent dielectric properties.

Result: The performance of touch screens and displays is significantly improved through application of a Nanize polysilazane formulation coating that has been ultra-rapidly cured, overcoming the need for frequent cleaning with chemical wipes. Electronic components such as OLEDs are sensitive to both elevated temperatures above 100°C and ingress of moisture. Nanize coatings, which can be readily applied using standard high-volume industrial processes and cured quickly at temperatures below which damage might occur, protect sensitive devices from their environment.

The dielectric properties of Nanize coatings make them especially suitable for use in batteries and other electronic assemblies.

Construction & architecture

Anti-graffiti and anti-soiling coatings reduce maintenance on façades, glass, and public infrastructure.

Problem: The exterior skins of buildings, such as claddings and curtain walls, are exposed to seasonal weather extremes and need to both retain their performance in protecting the building envelope as well as not visibly deteriorate in appearance through corrosion, soiling or graffiti.

Solution: Through applying a Nanize polysilazane formulation coating to the typically used, steel or aluminium building skin material, followed by ultra-rapid curing in a high throughput manufacturing process, a durable, corrosion-resistant surface that is hydrophobic, non-marking / anti-graffiti and not prone to soiling is created.

Result:The benefits of creating a long-life building skin that retains both its architectural appearance and functional performance whilst not requiring frequent cleaning from the build-up of dirt or the removal of graffiti are both economic and aesthetic. The fact that such building materials are manufactured in high volumes on high-speed production lines is not compromised thanks to the standard industrial processes for applying the Nanize coating, such as spraying and the ultra-rapid curing in less than one minute, below 70°C.

Industrial manufacturing

Problem: In highly automated, high-speed, industrial manufacturing processes, downtime due to wear of equipment surfaces is a high cost. The root cause of this problem is typically due to interface friction between machine components and or the product being manufactured. This can often be overcome using an oil-based lubricant, but may then require cleaning of the product to remove any residue before further processing or sale.

Solution: Nanize ultra-rapidly cured polysilazane coatings are inherently extremely low-friction and can be applied to a wide variety of substrates, whether production machine parts, on the product being manufactured or both.

Result: Through creating slippery, low coefficient of friction durable coatings, equipment runs more efficiently with lower energy costs, reduced downtime to replace worn parts and a reduction in damage to finished products caused by surfaces rubbing against each other. High volume production of small and delicate bottles being transported along conveyors with multiple touch points between bottles and the equipment is an application where Nanize formulation ultra-rapidly cured polysilazane coatings can be applied to both the bottles and the production equipment for improved efficiency, less waste and reduced cost.

Find out more about how Nanize can provide you with coatings without compromise and cure your coating problems. Please connect with Jerry Stokes, Chief Commercial Officer, js@nanize.com.