The Horizon Europe PEARL project has made significant progress towards its targets to develop next-generation flexible perovskite solar cells.

Offering material abundancy, light absorption capabilities, and low-cost production, perovskite materials are a popular option in research and development (R&D) activities across the globe. In particular, researchers have been keen to explore the use of perovskite materials within solar cells, to offer a high efficiency and low-cost alternative to silicon cells. However, whilst perovskite solar cells are reaching the efficiency of silicon cells, the stability is still an issue. Additionally, while silicon is fabricated via energy-intensive technologies, perovskite may be processed via low-cost, roll-to-roll (R2R) techniques enabling high-throughput, cost-effective production of flexible and lightweight perovskite solar cells. To address these challenges, the European Union (EU) launched the PEARL project – an innovative initiative aiming to enhance perovskite solar cells with cutting-edge carbon electrodes.

The mission of the PEARL- Flexible Perovskite Solar Cells with Carbon Electrode project is to significantly improve the efficiency, stability, and cost effectiveness of perovskite solar cells, targeting efficiencies of more than 25% and substantially lower production costs. Funded through the Horizon Europe programme, PEARL focuses on the advancement of perovskite solar cell technology by incorporating carbon electrodes into perovskite solar cell architecture.

Project partners

The project’s consortium consists of ten European partners who are working to develop flexible perovskite solar cells using scalable, environmentally friendly methods that are viable for industrial application. The partners represent two universities (University of Rome Tor Vergata and University of Applied Sciences Northwestern Switzerland); five research and technology organisations (VTT Technical Research Centre of Finland Ltd, Netherlands Organisation for Applied Scientific Research TNO, Helmholtz Centre for Materials and Energy, Fraunhofer FEP, and Institute of Chemical Research of Catalonia); two small and medium-sized enterprises (Dycotec Materials Ltd. and Saule Spółka Akcyjna); and one large enterprise (Eni S.p.A.).

Each partner has a key role in the project. University of Rome Tor Vergata is developing the high efficiency flexible cells and modules with small area deposition techniques, in collaboration with Fraunhofer FEP, Institute of Chemical Research of Catalonia (ICIQ-CERCA), and Helmholtz Centre for Materials and Energy (HZB). The University is also optimising the module design to reduce the cell-to-module losses. Another university partner, University of Applied Sciences Northwestern Switzerland (FHNW), performs the Life Cycle Analysis (LCA) and develops recycling scenarios for the photovoltaic (PV) devices and materials.

HZB is responsible for developing stable, high-performance perovskite cells and is studying their degradation mechanisms in detail. ICIQ-CERCA is designing and synthesising stable charge transport materials to be applied in the devices.

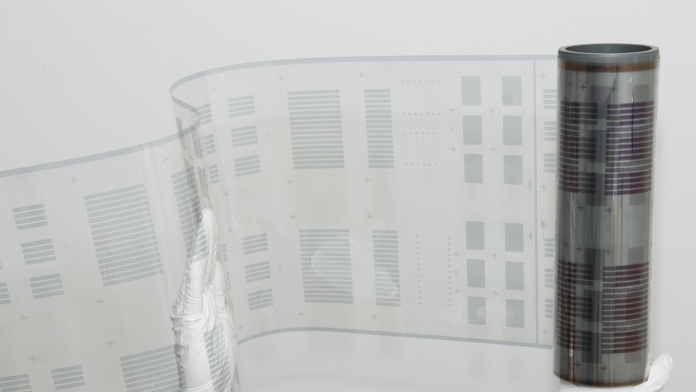

The perovskite materials and cell architectures are processed into modules by the upscaling partners TNO and VTT, on functional substrates provided by Fraunhofer FEP. TNO and VTT use their pilot-scale infrastructures (Solliance, PrintoCent) to fabricate the perovskite solar cells and modules with high-throughput, roll-to-roll (R2R) techniques and Fraunhofer FEP utilises their R2R vacuum-based coating infrastructure to fabricate flexible, transparent electrodes and barrier foils. HZB, FHNW, TNO and Eni also use their facilities to perform thorough stability testing under both indoor and outdoor conditions.

Dycotec Materials is providing and developing the carbon inks, barrier adhesives for the encapsulation, and antireflection coatings. Energy company Eni is using its facilities to study the module power production, utilising both indoor and outdoor test facilities for the energy yield assessment of PEARL flexible perovskite modules.

Major breakthroughs

Now at the halfway point of the three-year project, the PEARL consortium has made decisive progress toward its target of 25% efficient, low-cost flexible perovskite solar cells with carbon electrodes. By combining cutting-edge materials research, pilot-scale roll-to-roll manufacturing and comprehensive sustainability measures, the partners have delivered a series of significant achievements.

Collectively, the researchers have successfully developed solar cells with an efficiency of over 21% on flexible PET substrates. The most significant achievements of the project partners include:

- ICIQ achieved a power conversion efficiency of 21.6% through special surface treatments (molecular surface passivation with fullerene and silane self-assembled materials).

- University of Rome Tor Vergata achieved 17.03% using greener perovskite solvents and optimised blade-coating protocols.

- VTT demonstrated a lab-scale champion cell power conversion efficiency of 14.8% with a new printing process (gravure printed perovskite with DMSO-based ink).

- 9.1% power conversion efficiency with a fully R2R slot-die coated perovskite stack was achieved by TNO.

Alongside these milestones, VTT and TNO have scaled up R2R coating, printing, and patterning to larger formats and developed flexible minimodules with an area of 36cm² and a power conversion efficiency of 4.5%.

The consortium has also developed protective encapsulation that keeps the solar cells stable for over 2,000 hours under damp-heat conditions (85°C temperature and 85% humidity) – proving their durability for real-world applications.

Reflecting on these achievements, Dr Riikka Suhonen, PEARL Project Coordinator at VTT, said: “These achievements bring us firmly within reach of our 25% target – paving the way to low-cost, high-performance solar modules for applications from building-integrated photovoltaics to the Internet of Things.”

Sustainability is a strong focus of the project. So far, initial LCAs have shown that the use of carbon electrodes, recycled PET, and green energy can reduce the carbon footprint by more than 50%. In addition, processes have been developed to recover valuable materials such as lead and cesium from production waste.

What’s next?

As the project moves into its second half, PEARL will continue to optimise its roll-to-roll pilot manufacturing processes, test larger modules for outdoor use, and publish the results of the life cycle assessments. The goal is to bring flexible solar cells to market for applications such as building-integrated photovoltaics and the Internet of Things. Deliverables will include an optimised module design report, R2R encapsulation processes, and pilot-scale production protocols that collectively establish Europe’s leadership in flexible perovskite PV.

This project has received funding from the European Union’s Horizon Europe research and innovation programme under grant agreement no. 101122283.

This work was funded by UK Research and Innovation (UKRI) under the UK government’s Horizon Europe funding Guarantee [grant number 10097706].

This work has received funding from the Swiss State Secretariat for Education, Research and Innovation (SERI).

Please note, this article will also appear in the 24th edition of our quarterly publication.