With tightening regulatory deadlines, the transition away from legacy PFAS-based firefighting foams has become increasingly urgent. ProDecon® has established itself as a trusted technical partner in PFAS decontamination, supporting the firefighting sector in delivering best-practice transitions and assured regulatory compliance.

Across Europe, end users of firefighting foam are rapidly transitioning from C8 and C6 Class B foams to fluorine-free alternatives (F3). Yet, a central question continues to divide the industry: Is chemical decontamination necessary to remove residual PFAS within systems, or can systems simply be water-rinsed, or even left unrinsed before switching to F3?

ProDecon® and Tetra Tech have successfully decontaminated over 200 fire suppression systems across the UK and EU, which has enabled us to develop a vast amount of expertise within this sector. Together we have supported a range of different systems, including:

- Tanks (atmospheric & bladder)

- Pipework

- Fire tenders / tankers

- Sprinkler networks

- Marine vessels

- Jetty systems

- Pumps and proportioners

Over this time, we have continued to invest and develop our methodologies to improve the efficiency of decontamination, reducing waste and therefore the cost of disposal. Our experienced team provides a full-service delivery with specialist manpower and mobile equipment to bring a local solution to our customers’ sites all over the world, ensuring the best results in the fastest times.

This article explains why chemical decontamination is essential to a successful transition away from legacy PFAS-based foams and outlines the risks, limitations, and liabilities associated with relying on water rinsing alone.

Background to PFAS

C8 and C6 Class B firefighting foams, including aqueous film forming foam (AFFF) and fluoroprotein foams (FFFP and FP), contain a group of synthetic fluorosurfactant chemicals known as per- and polyfluorinated substances (PFAS), which comprise thousands of individual chemical compounds. Many have been shown to be persistent, bio-accumulative, toxic, and have proven links to multiple diseases in humans and fauna. PFAS have been used in firefighting foams since 1962.¹ Globally, they have been widely distributed within the environment and detected at high concentrations in groundwater, surface water, and soils surrounding fire training areas. This has given rise to more stringent regulations surrounding their manufacture, use, and transport.

Regulations

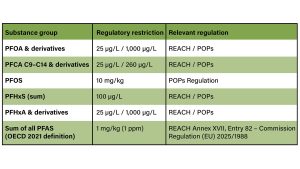

There are numerous regional, national, and global regulations under Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) and the Stockholm Agreement restricting the use, manufacturing, and sales of PFAS foam. These require companies to transition away from foams that exceed the following thresholds:

These regulatory pressures make effective decontamination a critical prerequisite for compliance.

Why decontaminate?

Current regulations specify at what concentrations PFAS (as a group or a singular compound) can be present within foam concentrate and the time period in which the transition to F3 foams needs to be completed.

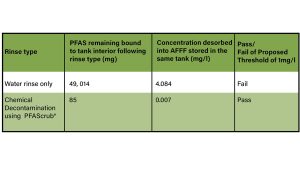

One known concern, associated with fluorosurfactants within C8 and C6 firefighting foams, is their ability to bind and form self-assembled structures on the interior of fire suppression systems. The hydrophobic (water-repelling) characteristics of certain PFAS compounds reduce the ability of water (even when hot) to effectively remove PFAS bound to the interior surface of fire suppression systems. Therefore, post foam transition, significant concentrations of the bound PFAS can slowly desorb back into the replacement F3 foam exceeding regulatory limits, thus defeating the goal of the transition with economic and environmental consequences.

Double or triple rinsing with water has been proven to be ineffective at removing bound PFAS from fire suppression systems.

ProDecon® and Tetra Tech have partnered to deliver specialised decontamination of fire suppression systems previously containing PFAS foams. The partnership has extensive experience assisting public and private clients in transitioning to F3 foams.

Chemical decontamination, using a known, biodegradable reagent such as PFAScrub®, has been proven to effectively remove PFAS layers adhered to the interior suppression systems through circulation to reduce companies’ future liabilities.

Each decontamination scope presents unique system configurations, material compatibilities, and contamination profiles. ProDecon® applies its specialised experience to design bespoke methodologies for every installation. This ensures the most cost-efficient and operationally practical solution, while optimising reagent contact time, circulation pathways and representative analytical verification. Our approach shortens transition timelines, reduces the overall volume of PFAS-containing waste generated, and maintains the highest standards of quality.

Decontamination validation

Verification using a water sample following water rinsing can indicate a false negative, as the majority of the PFAS will remain bound to the interior surface of the fire suppression system, rather than suspended within a water sample. To validate decontamination success, a surface TOP Assay swab should be carried out to qualify the PFAS ‘rebound’ risk.

The chemical decontamination process should draw upon multiple lines of evidence to support a successful decontamination and provide assurance the system meets current and proposed regulatory limits. ProDecon® provides up to three lines of evidence following decontamination utilising third-party accredited laboratories. The lines of evidence can include:

- Reduction in PFAS absorbed to surfaces: Determined via swab sampling submitted for TOP Assay analysis.

- Predicted PFAS rebound concentrations in new F3 foam: Based on residual PFAS mass on surfaces and its expected desorption profile.

- Absorbable Organic Fluorine (AOF) or Total Organic Fluorine (TOF) uptake: Measurement of PFAS mass removed during the chemical circulation process.

TOP Assay swab analysis

To determine the success of decontamination, a specific area of the tank’s inner surface (that has been in contact with firefighting foam) should be swabbed to analyse PFAS on the tank’s surface. Swabbing can be complex and should only be carried out using proven methodologies and trained personnel to ensure sample quality and maximum uptake of remaining PFAS on a system wall.

Swabs should be submitted for TOP Assay analysis, which is a chemical analysis technique used to quantify the concentration of terminal PFAS and PFAS precursors. TOP Assay analysis is a hydroxyl radical-based oxidation reaction that converts PFAS precursors (non-measurable PFAS that transform to form terminal compounds such as PFOA and PFOS) to measurable perfluoroalkyl acids (PFAAs), which are then detected and quantified. The swab test enables us to detect 16 terminal compounds and their precursors. By undertaking swab TOP Assay analysis, we’re able to determine the percentage reduction over the course of decontamination, and the PFAS concentrations that remain, which could rebound into the new F3 foam over time.

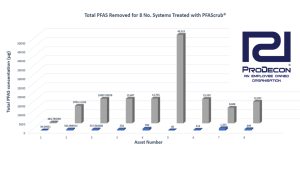

Utilising TOP Assay swabs, we’ve been able to observe trends on multiple foam systems, which support the inadequacy of water flushing as a decontamination process when transitioning. Figure 1 below compares post water flush swab sample concentrations (grey) to post chemical decontamination (blue) on eight foam storage assets.

Utilising the swab data, we’re able to determine the effectiveness of both water and chemical reagents during a decontamination process and whether the regulatory thresholds have been met, as demonstrated in Table 1.

AOF analysis

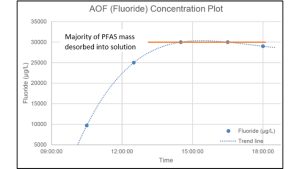

AOF and TOF are analytical methods used to analyse a wide range of PFAS in water. Within the decontamination process, it is used as an indicator for the mass of PFAS removed from the surface of the systems and suspended into the circulated solution during the decontamination processes. Multiple AOF liquid samples are collected during the decontamination process and allows us to determine the rate of PFAS extraction over the course of PFAScrubTM circulation.

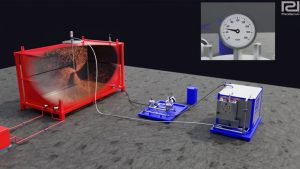

ADAPT™ technology

ProDecon’s latest innovation, ADAPT™ (Advanced Decontamination and PFAS Treatment), offers clients an alternative solution to reduce decontamination waste and cut overall project costs.

At the heart of ADAPT™ is a multi-stage treatment process engineered to deliver greater than 99% reduction in PFAS concentrations in the aqueous effluent, including regulated short and long chain compounds. The system has undergone extensive research and development, demonstrating consistent performance even on waste streams with very high PFAS concentrations – a challenge that has pushed existing technologies to their limits.

ADAPT™ leverages ProDecon’s proven field experience alongside new proprietary treatment stages to achieve levels of reduction that meet, and in many cases exceed, current regulatory expectations.

One of ADAPT’s standout advantages is its ability to reduce decontamination waste volumes by up to 90%. Traditional PFAS decontamination projects often generate large quantities of waste that must be transported, stored, and ultimately destroyed, driving up both cost and environmental impact.

By dramatically minimising waste output, ADAPT™ not only reduces logistical and disposal burdens but also enhances the overall sustainability profile of decontamination projects. For operators facing tightening ESG requirements, ADAPT™ delivers a compelling environmental and commercial benefit.

Recognising the need for flexibility in industrial operations, ProDecon® has designed ADAPT™ as a fully mobile treatment solution. From 2026, the system can be deployed directly on customer sites, avoiding unnecessary transport of contaminated materials, and can treat high-risk waste at source.

As PFAS transition deadlines approach, technologies like ADAPT™ will be instrumental in helping industries achieve compliance responsibly, efficiently, and sustainably.

Conclusion

Organisations holding PFAS foams (C6 or C8) need to be aware of current regulations and transition timelines. Companies are required to transition to F3 foam within the industry-specified derogation timeframes to avoid business liability, reputation damage and fines in the event of foam release.

Our studies demonstrate that chemical decontamination is required to reduce the risk of PFAS rebound and recontamination of future F3 foams. The only consideration remaining should be which chemical decontamination method is most suitable for the system, considering effectiveness of the clean, costs, downtime of assets, verification methods and minimising waste volumes.

References

- MacKay, N., A Chemical History of 3M 1933-1990. 1991, Minneapolis, Minnesota: The 3M Chemical, Film & Allied Products Group

- Annex A and B of the Stockholm Convention, Accessed https://www.pops.int/TheConvention/ThePOPs/AllPOPs/tabid/2509/Default.aspx

- European Chemical Agency, Accessed https://echa.europa.eu/documents/10162/f9e7b269-87cd-fc26-1a8e-b8c8b6e40c08,

- REACH Annex XVII, Entry 82 – Commission Regulation (EU) 2025/1988, Regulation – EU – 2025/1988 – EN – EUR-Lex

About ProDecon®

ProDecon® is a leading provider of turnkey chemical cleaning, refinery, and PFAS decontamination. Our strategy is focused on meeting customers’ needs by safely delivering the highest quality of service when restoring asset performance, process flow and heat transfer efficiency. Decontamination and chemical cleaning are our core business.

We have a rich heritage in delivering chemical cleaning solutions across a range of industries and appreciate the complexity of different assets, and can adapt our engineering processes and chemistry to support the specific demands of our clients.

In order to provide clients with industry-leading solutions, we have engineered bespoke equipment, invested in highly experienced field engineers and developed our own proprietary chemistry to offer each client across all sectors the specialist service they require, safely, within budget and on time.

Our experienced team provides a full-service delivery with specialist manpower and equipment to carefully control the chemical application, ensuring the best results in the fastest times.

Disclaimer

ProDecon®, PFAScrub® and its logo is a Registered Trade Mark. All rights protected. The Article is provided for information. It does not constitute legal, financial, or regulatory advice. Any decision to proceed with PFAS decontamination remains solely with the client, who must assess the associated risks independently and seek their own professional advice where appropriate.