From innovation to implementation, PFASuiki is pioneering a new approach to eliminating ‘forever chemicals’.

In the global race to tackle ‘forever chemicals,’ PFASuiki is transforming ambition into action. The startup is scaling up its breakthrough electrochemical oxidation (EO) systems and expanding its team of engineers, scientists, and field experts to deliver permanent PFAS destruction.

PFAS (per- and polyfluoroalkyl substances) are a class of over 10,000 synthetic compounds prized for their water and heat resistance – but infamous for their persistence. They accumulate for decades, posing serious health and ecological risks. Traditional water treatment systems only capture PFAS, but don’t destroy them.

PFASuiki’s approach is different. By using precision-engineered electrodes and proprietary system design, PFASuiki’s EO technology breaks the carbon-fluorine bonds that make PFAS nearly indestructible. The result is true mineralisation – permanent elimination rather than displacement.

The ESG and regulatory context

PFAS are increasingly recognised as a defining environmental issue of our generation. Governments are tightening restrictions, waste disposal costs are soaring, and industries face growing scrutiny.

- The EU and several Member States are moving toward PFAS phase-outs and incineration bans.

- PFAS-contaminated waste can exceed €2,000–3,000 per tonne for disposal.

- Global litigation around PFAS pollution has already reached billions in damages.

On-site PFAS destruction offers a clear path to compliance, cost control, and ESG leadership. PFASuiki’s modular EO systems enable this with a sustainable, future-proof solution.

From concept to capability: Turning research into results

Since its inception, PFASuiki has been driven by a clear mission: to turn PFAS destruction from a lab curiosity into an industrial reality.

Emerging from TDK, a globally recognised Japanese electronics company, PFASuiki benefits from world-class materials expertise and engineering depth. Today, as an independent startup, it combines that legacy with startup agility – building, testing, and refining systems in its own laboratories to deliver results faster and smarter.

A growing team of chemists and engineers is now taking this innovation from prototype to pilot scale. Hands-on development, rigorous analytics, and continuous testing are at the heart of PFASuiki’s progress.

How it works: Precision-engineered PFAS destruction

Electrochemical oxidation is not new – but PFASuiki’s version of it is.

Advanced electrode materials and system architecture enable high efficiency and long operating life. Here’s what makes the technology stand out:

- Direct electron transfer (DET) enables the targeted breakdown of PFAS molecules at the electrode surface.

- Indirect oxidation via radical species enhances overall destruction efficiency, addressing PFAS and other organics simultaneously.

- Recyclable electrode materials reduce environmental impact and operational cost.

- Modular system design makes the technology easily scalable – from pilot setups to industrial wastewater plants.

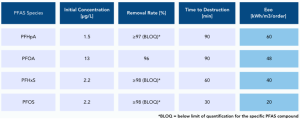

The outcome: a high-efficiency PFAS destruction system that operates with minimal chemical additives and competitive energy input (15-30 kWh/m³/order).

Proven in complex environments: The landfill leachate challenge

Among the toughest PFAS matrices is landfill leachate — a mix of organic matter, salts, and a variety of contaminants. PFASuiki’s prototype systems have already demonstrated that real-world performance can match lab results.

- 95% PFAS destruction for long-chain compounds (PFHpA, PFOA, PFHxS, PFOS) in 30–90 minutes.

- Stable operation even at high organic loads (Total Carbon >4.5 g/L).

- Strong potential for short-chain PFAS degradation through ongoing optimisation.

These results show that PFASuiki’s EO systems can handle complex, high-strength wastewaters – paving the way for scalable PFAS destruction at landfills, chemical plants, and industrial sites.

Why PFASuiki’s solution stands out

While many approaches promise PFAS removal, few deliver true elimination. PFASuiki’s technology enables clients to close the loop – capturing and destroying PFAS on-site, without creating new waste or liabilities.

Key advantages:

- Permanent destruction: Breaks down PFAS into harmless components.

- Energy efficient: Optimised electrodes reduce power demand.

- Plug-and-play operation: Easy integration with existing treatment infrastructure.

- Low maintenance: Durable, long-life electrode materials minimise downtime.

- Environmentally responsible: No chemical additives, no secondary pollution.

Broadening the impact: From PFAS destruction to comprehensive PFAS solutions

PFASuiki’s core strength lies in advanced electrochemical systems for PFAS destruction in water, providing a permanent and sustainable solution for one of the most challenging contamination pathways.

At the same time, PFASuiki has already evolved beyond pure technology development to become a comprehensive PFAS solutions partner – supporting clients across the full lifecycle of PFAS management.

Ready to take action?

Become a pilot customer and experience how PFASuiki’s technology can deliver permanent, compliant, and sustainable PFAS destruction. Contact us to explore a tailored pilot project for your site or application.