The PROMISERS project is developing sustainable alternatives to PFAS for use in proton exchange membrane fuel cells and electrolysers.

Green hydrogen is widely recognised by the European Commission as a key pillar of the EU’s clean energy transition. Fuel cell and electrolyser technologies are expected to play a vital role in meeting Europe’s emissions reduction targets, particularly in sectors that are difficult to electrify. Among these technologies, proton exchange membrane (PEM)-based fuel cells and electrolysers stand out as the most mature and commercially viable solutions, currently dominating both installed capacity and projected near-term growth.

However, all PEM-based hydrogen technologies today rely on per- and polyfluoroalkyl substances (PFAS) – a group of thousands of synthetic chemicals used extensively across the EU and globally. Ultimately, these chemicals transform into persistent substances, which can lead to irreversible environmental exposure and accumulation in human tissues, associated with adverse health effects.

Per- and polyfluoroalkyl substances (PFASs) in hydrogen technologies: A challenge and an opportunity

PFAS are essential to manufacturing hydrogen-related products. This is particularly true for fuel cells and electrolysers, which are typically being operated using a PFAS-based membrane, most commonly PFSA (perfluoroalkylated sulfonic acids) such as NafionTM. This material exhibits very good conductivities due to its intrinsic microstructure (microphase separated, ion conductive channels), while being chemically and mechanically robust. Also, in the gas diffusion layer (GDL), catalyst layer, microporous layers (MPL), and electrodes, PFAS ionomers are extensively used. Currently, no commercially viable alternatives present desirable physical and chemical characteristics of the fluoropolymers, and a ban on PFAS without a suitable alternative would have destructive effects on the industry’s €30bn worth of investment in a decade (only including electrolysers and fuel cells).

Alternative promising materials, such as hydrocarbon-based polymers and cellulose, have potential to substitute the current PFAS-based materials. The aromatic hydrocarbon-based specialty polymers and mesoporous polymers exhibit high thermal, chemical, and mechanical stability in acidic media, attributed to their aromatic structure. And cellulose, on the other hand, is the most abundant biopolymer, and its nanoscale forms, cellulose nanocrystals (CNCs) and cellulose nanofibrils (CNFs), are interesting materials for engineering key components for fuel cells and electrolysers.

The PROMISERS project

The PROMISERS project was launched to address the lack of suitable PFAS alternatives and to develop new non-fluorinated materials, paving the way for fluorine-free PEM fuel cells and electrolysers.

The PROMISERS project aims to develop sustainable industrial processes to produce PEM fuel cell and PEM electrolyser stacks using non-fluorinated components and materials. These include ionomers, membranes, membrane electrode assemblies (MEA), MPL, electrodes, and sealing elements. The final goal of the project is to demonstrate the competitive performance, durability, and efficiency of these newly developed materials in fuel cell and electrolyser stacks.

In addition, the project aims to validate circularity-by-design and the business potential of the materials, scale-up strategies, and production processes – both at the process level and across the entire value chain. This will be achieved by applying simulation approaches, safety-by-design protocols, REACH compliance, and conducting life cycle assessment (LCA) and life cycle costing (LCC) evaluations. These efforts ensure alignment with the European Green Deal priorities and the EU’s zero pollution ambition. Throughout the project, materials and components will progress from technology readiness level (TRL) 1 to TRL 4, moving from fundamental research and concept validation to laboratory-scale demonstration in relevant environments.

This project is funded by the Horizon Europe programme of the European Commission, with the support of the Clean Hydrogen Partnership. Formed by a consortium of European leaders in industry and research, PROMISERS has a duration of three years and a budget close to €3m. The consortium members include: Syensqo (France, Italy), Fumatech (Germany), De Nora (Italy, Germany), RINA Consulting (Italy), Hysytech (Italy), TNO (The Netherlands), IIT (Italy), Cellfion (Sweden), and Leitat (Spain) as coordinator.

From concept to validation: Key developments in the PROMISERS Project

The project follows two main approaches for the development of non-fluorinated components for PEM fuel cells and electrolysers. The first approach is based on hydrocarbons, and the second approach is based on nanocellulose. Each pathway begins with PFAS-free ionomer development and ink formulation, followed by MEA and single-cell design, and culminates in the fabrication and validation of PEM fuel cell and PEM electrolyser stacks (Hysytech). The non-fluorinated components development is supported by simulation studies and operando techniques (TNO, IIT).

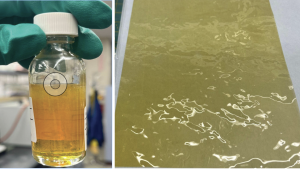

The project officially kicked off at Leitat facilities in January 2025 and is progressing well. Syensqo has developed the first new hydrocarbon-based ionomer, which has been distributed to consortium partners for developing and characterising components such as the PEM membranes (Fumatech) and ink formulations (De Nora). The initial characterisation results of the material are very promising. The consortium partners are currently focusing on process optimisation of the material to comply with the REACH regulations and safety-by-design protocols to screen the possibility of upscaling the materials on an industrial level and producing higher quantities by the end of the project (RINA).

In parallel, Cellfion and Leitat are advancing the biobased approach by optimising the cellulose nanocrystals (CNCs) and cellulose nanofibrils (CNFs) materials to enhance membrane performance. Additionally, biobased nanofiber reinforcement materials are screened to improve the mechanical stability of the PEM membranes. The first PEM membranes samples have been developed and are currently undergoing performance testing.

With successful implementation of the PROMISERS concept, a reduction of about 500 tonnes of PFAS material can be achieved by 2030 based on a prospective demand of 100,000 trucks and 1 million light vehicles for fuel cells. Regarding electrolysers, a similar amount of 500 tonnes could be reduced for 40 GW of electrolysis capacity by 2030.

Disclaimer

Project PROMISERS with Grant Agreement number 101192151. The project is supported by the Clean Hydrogen Partnership and its members. Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the Clean Hydrogen Join Undertaking. Neither the European Union nor the granting authority can be held responsible for them.

Please note, this article will also appear in the 24th edition of our quarterly publication.