A new high-performance precision-manufactured germanium diffracting crystal design for wavelength dispersive spectrometers has received an award for its contributions to efficiency and accuracy in microscopy.

When it comes to microanalysis, precision and accuracy are paramount. The development of a new high-performance precision germanium diffracting crystal, specifically designed for wavelength-dispersive spectrometers, presents a significant advancement in this field. Developed collaboratively by Concord University, Rigaku Innovative Technologies, and Advanced MicroBeam, Inc., the precision germanium diffracting crystal promises to enhance the capabilities of microanalysis, offering enhanced accuracy and efficiency for various analytical studies. Following successful field test results, the crystal’s potential is clear, having now been recognised as one of the ten best microscopy innovations in the 2025 Microscopy Today Awards.

Introducing Ge <111> crystals

The Rigaku Innovative Technologies (RIT) Ge crystal offers a high-performance, single crystal, Johansson-type diffracting element designed for wavelength-dispersive X-ray spectrometers (WDS), commonly used in Electron Probe Micro Analysis (EPMA) and X-ray Fluorescence (XRF) instruments.

Manufactured from high-purity, semiconductor-grade germanium (Ge), these crystals are created using a unique production process which:

a. Uses elastic bending to eliminate lattice distortions typically caused by conventional bent crystal manufacturing techniques; and

b. Produces exceptionally high-quality crystal surfaces.

These properties result in significantly improved X-ray focusing precision, leading to enhanced X-ray spectral resolution and intensity for end-user applications.

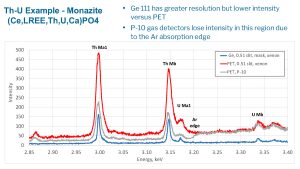

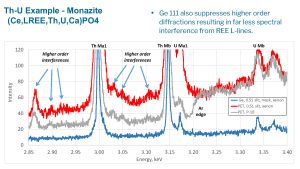

The Ge <111> crystals designed for EPMA offer a spectral range similar to that of PET crystals but are somewhat shifted toward shorter X-ray wavelengths and higher energies. They provide superior analytical performance compared to LiF and PET crystals in key aspects such as intensity, peak-to-background ratio, predicted detection limits, peak widths, and the ability to separate closely spaced X-ray lines. Additionally, Ge <111> crystals suppress higher-order diffractions, thereby minimising spectral interferences.

High-performance Si <111> and Si <222> crystals produced using a similar method are also available, and other crystallographic orientations and materials can be provided by RIT upon request.

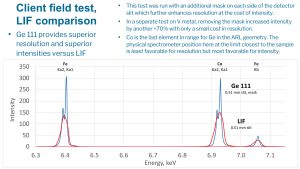

Client field test: LIF Comparison

In the field test conducted on an ARL SEMQ electron microprobe, an additional mask was placed on each side of the detector slit, which enhanced the resolution but reduced the intensity. In a separate assessment of V metal, removing the mask resulted in a significant increase in intensity by approximately 70%, with only a minor compromise on resolution. It’s important to note that cobalt (Co) is the last element within the range for germanium (Ge) in the ARL geometry. At this position, the physical spectrometer is situated closest to the sample, which, while not ideal for resolution, is most favourable for intensity.

Benefits compared to previous methods

In traditional WDS analysis, when multiple diffractor options are available for a specific element, there is often a trade-off between intensity and resolution. You can prioritise either stronger signal strength or better peak width and peak-to-background ratios, but achieving both simultaneously typically is not possible. This trade-off is evident when comparing the commonly used PET and LIF diffractors, where PET provides higher intensity and LIF offers improved resolution.

However, the precision Ge <111> crystal from Rigaku Innovative Technologies (RIT) enhances both intensity and resolution simultaneously compared to LIF. Using the same EPMA test conditions, the Ge <111> crystal produced over double the intensity of LIF for iron (Fe) and cobalt (Co) while also resulting in much narrower line widths.

In a test analysis of trace barium (Ba) using the La line, the detection limits with the Ge <111> crystal were nearly three times lower than those obtained with LIF under the same acquisition parameters. Additionally, the Ge <111> crystal significantly reduces potential interference from nearby titanium (Ti) Kα lines.

In an EPMA test for thorium (Th) and uranium (U) in monazite, where LIF analysis was unfeasible, the Ge <111> effectively eliminated higher-order interferences from rare earth element (REE) L-lines, which could otherwise complicate the accurate measurement of X-ray backgrounds.

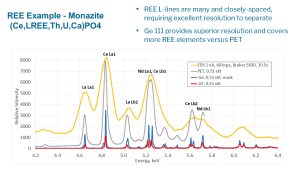

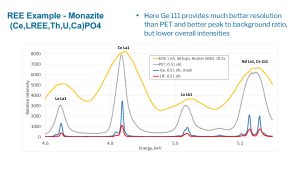

A solution for the challenges of REEs

Over the past few decades, trace-element analysis has become a more prevalent application for EPMA instruments, a shift largely driven by advances in system stability, software enhancements, and the introduction of larger crystals and detectors in EPMA, alongside the progress made in SEM-EDS for major-element analysis. However, many EPMA instruments still rely on the same suite of TAP, PET, and LIF diffracting elements commonly used in the 1970s and 1980s. The Ge <111> crystal and similar alternatives have the potential to improve the analytical performance of these instruments, particularly as the demand for trace element applications continues to rise.

Furthermore, the importance of REEs has grown thanks to their critical role in various high-tech applications, which has simultaneously raised concerns about their availability and the security of the supply chain. Natural REE materials generally consist of mixtures of these elements, and the L-lines typically used for their analysis in X-ray spectroscopy are complex and closely spaced. This can result in spectral interferences that complicate accurate quantification. The use of the Ge <111> crystal may mitigate these challenges, thereby supporting both the development of REE materials and the exploration of new REE resources.

Potential applications

Most applications involving X-ray-based analysis of elemental abundances are likely to utilise instruments such as EPMA, benchtop X-ray fluorescence (XRF), and synchrotron XRF. In these contexts, Germanium <111> can outperform more commonly used diffracting elements like PET and LIF. This advantage is particularly useful for trace element quantification and in situations where X-ray spectral overlaps pose a challenge, such as with rare earth elements, barium-titanium (Ba-Ti) materials, and others. Additionally, Germanium <111> can serve as a substitute for PET or LIF in suitable spectral ranges, allowing for the observation of finer-scale patterns in X-ray spectra.

The Ge <111> crystal is not just an upgrade to existing technology, but a transformative leap that promises to redefine analytical possibilities in elemental analysis.

Please note, this article will also appear in the 24th edition of our quarterly publication.