Designed for complex water streams, SELPAXT’s innovative surfactant-ligand assisted membrane filtration (SAMF) technology is transforming the PFAS treatment landscape.

Widely considered to be one of the most persistent pollutants ever created, per- and polyfluoroalkyl substances (PFAS) present a unique problem. Ubiquitous in industrial applications, consumer products, and environmental matrices, these ‘forever chemicals’ resist natural degradation, bioaccumulate in living organisms, and pose serious risks to public health.

Despite increasing calls for a total ban on PFAS, manufacturers maintain they are irreplaceable across a number of applications. As a result, tighter legislation is being introduced to mitigate the environmental and health impact of PFAS.

From stricter limits under the EU’s Water Resilience Strategy, the Drinking Water Directive, REACH proposals, and country-level PFAS action plans to costly civil settlements and recent high-profile criminal convictions, the message is clear: effective PFAS elimination strategies are now essential.

While the need for effective and scalable PFAS treatments is ever-present, successfully eliminating PFAS from complex water streams has remained a formidable challenge.

But Chromafora’s SELPAXT technology is changing that.

Selective chemistry for PFAS removal: How it works

At the heart of Chromafora’s innovation lies a patent-pending solution: SELPAXT – a chemical-enhanced ultrafiltration process that selectively isolates and concentrates PFAS, including elusive ultra-short-chain variants.

Known as innovative surfactant-ligand assisted membrane filtration (SAMF), SELPAXT combines proprietary surfactant chemistry and optimised membranes to deliver unrivalled PFAS concentration rates.

SELPAXT operates similarly to conventional ultrafiltration systems but features proprietary, water-soluble, and biodegradable chemicals that are continuously dosed in accordance with the incoming water matrix. PFAS molecules are then selectively retained and concentrated on the membrane barrier and intermittently discharged at a rate as low as 0.1% residue to total water volume.

Using an ISO-certified, container-based modular format or customised installations, SELPAXT systems are rapidly deployable and tailored to site specifications. Similarly, requisite pre-treatments, such as filtration or oil separation, can be incorporated, based on the incoming water quality.

With low energy consumption and reduced environmental footprint, SELPAXT not only delivers a consistently low OPEX; it enables companies to optimise PFAS removal while enhancing sustainability. Unlike conventional separation and concentration techniques such as activated carbon, ion exchange, or foam fractionation, SELPAXT does not rely on adsorption or foaming. Instead, it uses proprietary selective chemistry to bind PFAS molecules and remove them through a pressurised membrane step, offering high selectivity without sacrificing flow or stability.

Due to its high selectivity, SELPAXT specifically captures PFAS molecules, without picking up additional or alternative contaminants, such as organics or salts. This makes it particularly well-suited to complex water streams, which are typically high in pollutants.

This approach delivers four technological advantages:

- Up to 99.7% removal efficiency

- Effective on ultra-short, short-chain, and long-chain PFAS molecules

- As low as 0.1% waste residue to total water volume

- High tolerance to complex water matrices with elevated TOC levels.

Up to 99.7% removal efficacy

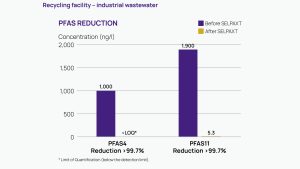

As tighter regulations are set to come into force, any PFAS producers and water treatment companies will need to up the ante when it comes to total PFAS removal. Proven to remove up to 99.7% of all PFAS molecules from complex water streams, SELPAXT’s innovative SAMF technology ensures a drastic reduction in PFAS levels (see Figs. 1 and 2).

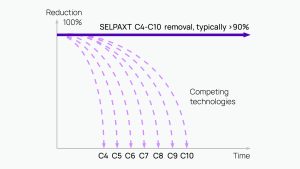

Crucially, SELPAXT consistently delivers up to 99.7% efficacy rates and maintains performance over extended time periods. Unlike other forms of PFAS treatment, such as GAC or Ion Exchange, SELPAXT doesn’t require frequent media replacements or constant manual monitoring. Instead, its high tolerance to contaminants means it’s unaffected by pollutants in complex water streams and able to maintain consistently high removal rates without costly media replacements or a high OPEX (see Fig. 3).

Effective on ultra-short, short-chain, and long-chain PFAS molecules

Existing PFAS treatments, including granular activated carbon (GAC), ion exchange, and reverse osmosis (RO), offer varying efficacy in removing long-chain PFAS molecules, but they offer limited efficacy when it comes to eliminating ultra-short or short-chain PFAS.

To date, much of the research into the harmful effects of PFAS has focused on long-chain molecules, and, therefore, the limited amount of regulation has also centred on long-chain PFAS.

However, a new era of regulation is in sight, and increasing awareness of the harmful effects of ultra-short and short-chain PFAS means a viable and cost-efficient method of elimination is essential.

Fortunately, SELPAXT is proven to be highly effective at removing any type of PFAS from complex water streams, including ultra-short and short-chain. As shown in Fig. 1, SELPAXT successfully reduced PFAS4 levels in industrial wastewater from 1,000 ng/l to below detectable limits at a customer’s site, thus exemplifying the high rate of efficacy SELPAXT has on short-chain PFAS.

With a range of case studies, lab tests, and analysis, SELPAXT’s ability to remove ultra-short, short-chain, and long-chain PFAS is well-documented and proven in real-world environments.

Less than 0.1% residual volume of PFAS waste

Like other existing PFAS removal technologies, SELPAXT works by separating and concentrating PFAS to facilitate subsequent destruction or sequestration. Unlike existing solutions, SELPAXT systems are able to concentrate PFAS waste down to just 0.1% residual volume. In contrast, reverse osmosis (RO) typically produces 15-25% residual waste.

For every 1,000 litres of water treated, for example, SELPAXT will produce just 1 litre of PFAS waste, compared to the 150- to 250-litre RO would produce.

As a result, customers using SELPAXT systems don’t need to facilitate secondary destruction as frequently. In turn, this can substantially reduce the costs associated with PFAS destruction and management.

High tolerance to complex water matrices with elevated TOC levels

Most existing PFAS technologies capture and concentrate long-chain PFAS, but in the process of doing so, they also capture any other contaminants in the water stream. As a result, any media used becomes quickly saturated and needs to be manually replaced on a frequent basis.

Conversely, SELPAXT’s high selectivity means it only captures PFAS molecules and continuously adds proprietary chemicals at the correct dose to achieve optimal PFAS reduction. With automatic ‘clean-in-place’ (CIP) between batches, no media replacement is required. This greatly reduces the costs associated with PFAS and ensures minimal on-site maintenance is needed.

Targeting short-chain molecules: A new era of PFAS removal

When water is contaminated with PFAS, it invariably contains a range of ultra-short, short-chain, and long-chain molecules.

When technologies are only capable of removing long-chain molecules, it limits the amount of total PFAS that can be successfully eliminated. As regulations become tighter, removing ultra-short and short-chain molecules will be a necessary way to ensure total PFAS concentrations remain below the mandated thresholds.

However, this isn’t the only reason why companies should be proactive about removing ultra-short and short-chain PFAS molecules from their water streams.

Increasing short-chain scrutiny

To date, PFAS regulation has focused almost exclusively on long-chain PFAS due to the comparatively large body of research into these types of molecules. In a bid to evade this regulation, savvy PFAS manufacturers shortened the carbon chain length, essentially turning a regulated long-chain PFAS molecule into an unregulated short-chain PFAS molecule.

However, increasing awareness of the potential health and environmental implications of short-chain PFAS, coupled with the desire to hold manufacturers and industry to account, means greater scrutiny is now being applied to both ultra-short and short-chain PFAS.

As a result, we’re likely to see an increasing body of regional, national, and international regulation targeting ultra-short and short-chain PFAS, as well as long-chain molecules. For companies that have relied on short-chain PFAS ‘flying under the regulatory radar’, effective short-chain removal technologies will now be essential.

The ‘polluter pays’ principle

In addition to focusing on long-chain molecules, much of the existing PFAS regulation has concerned drinking water, rather than wastewater or groundwater. This places the burden of removing PFAS on utility companies, which are often publicly owned, effectively tasking taxpayers with funding the cost of removing these ‘forever chemicals’.

This is in direct contrast to the EU’s broad, ‘polluter pays’ approach to environmental policy. Now, we can expect to see this principle being extended to the remit of PFAS treatment.

Already, some of the costs associated with compliance with the EU’s revised Drinking Water Directive are expected to be borne by the polluter. Whether a comparable framework to the ‘Extended Producer Responsibility’ (EPR) scheme and the UWWTD is introduced in relation to PFAS remains to be seen, but we can certainly expect increasing pressure to be placed on PFAS polluters and, therefore, higher demand for effective industrial wastewater PFAS treatment technologies.

Preparing for a PFAS-free future

While a total and unequivocal PFAS ban may be unlikely, increasing regulation means eliminating PFAS from wastewater, groundwater, and drinking water is imperative. No longer just a matter of reputational management, industrial manufacturers, utilities, and water treatment companies will need to enhance and optimise PFAS removal in order to achieve regulatory compliance, meet stakeholder expectations, and limit both civil and criminal liabilities.

Fortunately, SELPAXT by Chromafora provides a reliable and cost-efficient treatment that successfully removes up to 99.7% of ultra-short, short-chain, and long-chain PFAS. Used in isolation or in conjunction with technologies as part of a water treatment train, SELPAXT is already empowering companies to embrace a safe, sustainable, and PFAS-free future.

Please note, this article will also appear in the 23rd edition of our quarterly publication.