The Fraunhofer Institute for Silicate Research ISC is pursuing forward-looking material development by designing inorganic-organic hybrid polymer coatings (ORMOCER®) for PFAS-free surfaces.

PFAS (per- and polyfluoroalkyl substances) are frequently used in many industrial and commercial products and applications due to their outstanding properties, which are based on the unique strength of the fluorine-carbon bond which can nearly not be affected by any chemical attack. They are water-, dirt-, and grease-repellent, extremely heat-resistant, chemically stable, have very low friction coefficients, low surface energies, and low permeability to gases and liquids. In addition, because they are considered particularly durable and have relatively low production costs, they are indispensable in chemical, electrical, and automotive industries, mechanical engineering, medical technology, the textile industry, and in the areas of packaging and renewable energy systems.

Due to their mobility and, in particular, their high stability, PFAS can enter the environment, where they accumulate and pose an environmental pollution problem. At the same time, it has been proven that they accumulate in living organisms. In reputable studies, they are also associated with negative health effects.

Ban on critical substances: Where to find replacements

To address environmental issues and replace PFAS in a sustainable and regulatory-compliant manner, replacement materials must be found that fulfil the very high requirements of the aforementioned processes and products. In addition to basic chemical, physical, and technical functionality and performance, the alternatives should ideally cover a similar versatility of applications at competitive manufacturing costs so that they can be used in various application areas and are compatible with existing manufacturing processes and materials.

Given the long list of requirements and the broad range of applications, it is obvious that, based on current knowledge, none of the PFAS material alternatives will be a direct 1:1 replacement. This highlights the need to precisely define material specifications and required property portfolios and, where possible, to compromise on material selection, e.g., in terms of maintenance cycles, durability, etc. In this context, a conceptual rethinking, including new designs of existing products and processes, should also be considered.

Design of tailor-made, multifunctional coating materials as key to PFAS-free coatings

The Chemical Coating Technology Department at Fraunhofer ISC develops customised, multifunctional coating materials for various material types, such as glass, metals, plastics, and fibre-based materials, like paper and (technical) textiles. The coating as a finishing provides the substrates with improved or additional surface properties. This sustainable material design extends the service life of the substrate by applying a very thin coating, while at the same time expanding the selection of base materials available for a wide range of applications.

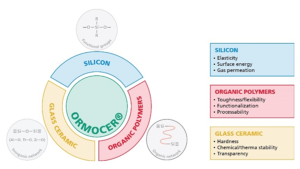

The designed coating materials are based on inorganic-organic hybrid polymers (ORMOCER® – organically modified ceramic and bioORMOCER®, Fig. 1). These hybrid materials combine the characteristic structures of inorganic, glass-like materials with organic structural units and have been continuously developed at Fraunhofer ISC for several decades. The formation of covalent bonds between the inorganic and organic domains combines the properties of both material worlds at the molecular level in a homogeneous composite material. By using this molecular design toolbox, the properties of the final layer can be individually adapted to the desired specifications and applications.

In addition to the inherent thermal stability up to 250°C at continuous load, the chemical resistance to acids, cleaning agents, solvents or oils (even at elevated temperatures for a long period of time), and the mechanical stability of the layer, the material platform enables a diverse portfolio of properties with just one functional coating layer. In this way, many properties known from PFAS materials can be achieved, facilitating their substitution. Applications range from packaging, textiles, automotive, and mechanical engineering to medical technology and aerospace.

In detail, ORMOCER®-coating materials are based on oligomers with an inorganic silicon backbone that are formed during synthesis. The organic network formation takes place primarily during the adaptive drying process and the thermally or UV-light-induced curing reaction. Through the molecular linking of inorganic and organic building blocks, very stable materials are created, enabling new combinations of properties.

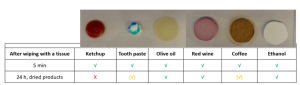

The use of functional silanes specifically designed for the intended application allows for the modulation of layer polarity, which in turn can enhance additional surface properties. These properties may include hydrophobicity, surface energies below 20 mN/m, dirt repellency, ease of cleaning (resistance to substances such as toothpaste, coffee, red wine, and certain oils), and antimicrobial effects. In addition, ORMOCER® coating solutions are processed at moderate conditions, are easy to scale-up, show very good adhesion to almost all types of substrates, and can be applied using all standard industry coatings processes, making this material platform a simple yet versatile tool for functionalising the surfaces of various substrate materials.

Fluorine-free coatings for textiles and food packaging

Based on the ORMOCER® technology, repellent coating formulations were developed, resulting in the ZeroF project. The goal of this EU project is the development of fluorine-free coatings for textiles and food packaging based on renewable raw materials and non-toxic compounds. Fraunhofer ISC works on safe and sustainable PFAS-free coating solutions with a comparable performance especially in terms of water and oil repellency.

The whole material research and development is performed following the SSbD (safe and sustainable by design) framework. Accordingly, all developed material alternatives are assessed in terms of safety and performance, while all process steps are evaluated in the light of ecological and economic criteria. From this iterative process, guidelines for material design are developed and directly incorporated into material optimisation. Additionally, the consumer acceptance is evaluated, and exploitation strategies are developed by stakeholder engagement.

At Fraunhofer ISC, we focus on the design and development of omniphobic ORMOCER® coating formulations for functional textile applications, such as upholstery, to contribute to a safer, PFAS-free world.

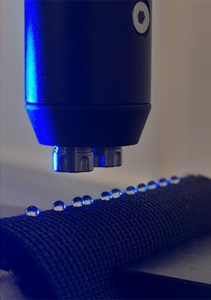

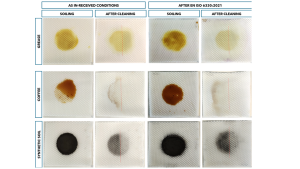

Although either the desired water or oil repellency itself can easily be addressed in a purely chemical sense, the combination of both properties remains challenging. Initial accomplishments in water repellency were achieved with water-based functional coating formulations. Grease resistance is being addressed by optimising ORMOCER®-based coating materials through tailored chemical composition and the introduction of surface patterning through nano- and micro-structuring by integrating particulate and chemical performance additives, such as e.g. silanes with long-chain alkyl chains or even silicone-based additives. This is an iterative process in which we work closely with our partners at VTT (Finland) on optimisation the synthesis procedures and with Leitat (Spain) on the coating formulation for textile substrates. Fig. 2 shows the water repellency of a ZeroF-textile coated with ORMOCER®, while the following Fig. 3 shows the cleaning properties of a coated fabric against grease, coffee, and synthetic soil.

Feedstock for further development of PFAS-free coatings

Through the implementation of the ZeroF project, we are learning a lot about the development of PFAS-free coating alternatives. We are acquiring fundamental knowledge about various strategies that can be applied and can use the knowledge we have gathered to further develop PFAS-free coatings for other applications. Specifically, at Fraunhofer ISC, we are working on various ORMOCER®-based PFAS alternatives for technical applications, such as easy-to-clean surfaces for furniture (see Fig. 4), anti-stick coatings in mechanical engineering, which can be used as mould-release agents in injection moulding or power sintering, thermal and UV-curable PFAS-free functional coatings for paper-based packaging solutions for food and cosmetics with high KIT-values, grease stability and the wet-chemical functionalisation of textiles. In the latter application, the adaptability of the ORMOCER® matrix is exploited by increasing the organic content and adding silicones to partially achieve additional oil repellency. Other potential areas of application include paints and anti-stick coatings, as well as coatings for personal care products or medical applications such as surgical instruments.

Another publicly funded project at Fraunhofer ISC, FNR-BioCoatTex, takes these developments to a new level of sustainability. While oil-repellent surfaces play no role here, bio-based coatings are being developed for bio-based textile applications (hemp fibres and bio-based synthetic leather) that make the surface water-repellent and easy-to-clean. In this project, biopolymers, such as cellulose, are incorporated into the hybrid layer matrix to achieve greater flexibility and biodegradability. Suberin (a plant-based hydrophobic biopolymer), sugar fatty acids, or chitosans are used to address hydrophobic properties. The formulations are then applied to the highly flexible substrates using industrially relevant methods. The goals are sustainable seat covers and construction modules reinforced with hemp fibres, where the ORMOCER® is intended to improve fibre-matrix adhesion and increase water resistance.

Please note, this article will also appear in the 23rd edition of our quarterly publication.