Marine and freshwater biodiversity holds the potential to enhance the bioeconomy by utilising sustainable practices, leveraging renewable resources, and fostering innovative technologies that improve environmental resilience and increase agricultural and medical treatments productivity.

On a cool Atlantic morning, marine biologist Dr Henrique Da Silva Pereira wades through the low tide shallows near Connemara. The long kelp ribbons sway in the water like dark-green banners. He carefully gathers samples into a chilled container.

“Seaweed which washes up on our shores,” he says, “provides crucial food, shelter, and nursery grounds for diverse marine life and are actually libraries of solutions for sustainable living.”

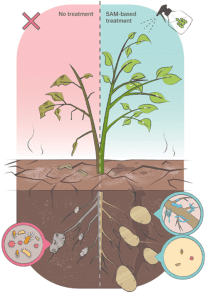

Led by Dr Antoine Fort, Dr Da Silva Pereira is part of the AMicrobioM project, which explores the tiny microbial communities that live and create ecosystems that interact with seaweed hosts. These microbes are configured by seaweed-specific chemical signals to provide essential benefits, including defence against pathogens and improved nutrient uptake. They have a remarkable capacity to generate bioactive compounds that can be used to grow healthier crops with fewer chemicals and develop crop resilience to climate change. This fusion of marine biodiversity and agricultural innovation is as yet largely unexplored.

Renewable biological resources, including crops, agricultural products, seaweed, microalgae and microbes, are core to the production of food, feed, energy, materials and services for the bioeconomy. For generations, the seas, fields and forests have fed and sustained populations. Today, new technologies and ideas are helping us harness these resources more efficiently and with a far smaller carbon footprint.

The bioeconomy brings together farmers, scientists, entrepreneurs and communities to create valuable products from renewable resources, such as: converting waste into animal feed, developing seaweed-based fertilisers, and even discovering innovative ways to produce sustainable plastics. This shift is not just about new technology; it’s about building a future economy that can meet our needs, create jobs and opportunities, and protect the planet. By developing our understanding of the intricate bio-interactive ecosystems and creating methods to harness their capabilities, novel antimicrobials can unlock an array of possibilities for future medical, agricultural and environmental applications.

At LIFE Research Institute, in Technological University of the Shannon, our ethos is to work in tandem with nature and nature’s cycles. Deploying expert understanding and talent to harness the operation of biological systems, biomaterial structure property relationships and their macroscopic function. Our researchers develop novel technologies and products to meet health and environmental challenges. These multidisciplinary activities encompass strategically important areas, including the sustainable use of renewable biological resources, the development of innovative biomaterials, and the creation of advanced biotechnologies that support health, environmental resilience, and a circular bioeconomy.

Living Lab

At a Peatland Transformed, inland on the windswept bogs of Mount Lucas in County Offaly, a pertinent venture is underway-. Once harvested for fuel, the land now hosts a circular bioeconomy hub powered by on-site wind turbines.

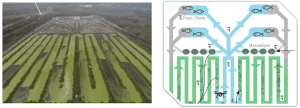

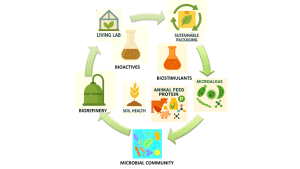

Led by Professor Neil Rowan, this peatland facility is a Living lab, a real-world testing ground where researchers, farmers, businesses, policymakers, and local communities work together to design, test and improve new solutions in everyday settings.

Channels of rainbow trout generate fish waste, containing ammonia and phosphate, which is consumed by duckweed, macroalgae and microorganisms, in turn yielding streams of biomass accumulation. These products then become sustainable ingredients for feed, food, biostimulants and bioactives in a full-circle system with virtually no waste.

Duckweeds (lemnaceae) grow rapidly and uptake a broad range of (in)organic pollutants. Microalgae absorb large amounts of CO₂, can be processed to produce biodegradable polymers and oils (lipids) that can be converted into biodiesel, bioethanol, or biogas as renewable energy sources that can replace fossil fuels.

A dedicated onsite biorefinery will process targeted extracted ingredients, including proteins, fibres and bioactives, for commercial applications spanning proteins for animal feed, nutraceuticals, composites and biostimulants for crop growth as greener alternatives to agrochemicals. By embedding these living lab innovations directly into the places where they will be operated, it allows producers, businesses and consumers to experience and adapt to new, commercially viable ways of working. This also serves to stimulate further ideas and generate answers to challenges. It acts as a centre of excellence, promoting zero waste and climate-action principles, with far-reaching impact at regional, national and global levels. Importantly, this peatland’s living lab ecosystem also provides on-site training for companies spanning circularity in action to bespoke use of extended reality.

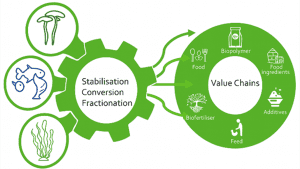

Biorefineries

Biorefineries are an essential element to establishing the bioeconomy. Their role is to integrate processes to convert renewable resources and biomass into a spectrum of high-value products and bioenergy. Nature’s biorefineries are highly complex and elegant. They include photosynthesis, where plants and algae act as ‘bioreactors,’ using sunlight, carbon dioxide, and water to create sugars, cellulose, and other compounds, which are the basic building blocks for energy and materials.

Human-operated biorefineries date back centuries, with pulp, paper mills and dairy processing as their early forms. Today, strong research and collaboration are serving to advance new generations of biorefineries incorporating microbial engineering, enzymatic catalysis, and process optimisation, enabling the sustainable production of energy and bio-based material products while reducing greenhouse gas emissions and dependence on fossil resources.

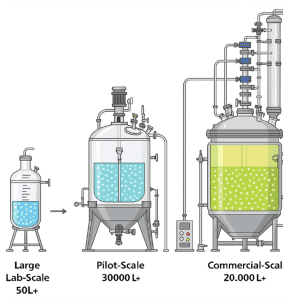

The Irish Bioeconomy Foundation (IBF) is preparing to open a 1,700-square-metre Bioprocess Pilot Plant which will be a test-bed for start-ups and co-operatives to turn ideas into market-ready bio-products. This world-class facility, with modular and confidential processing spaces, will enable innovators to bring bio-based products ranging from green chemicals to next-generation food ingredients, from concept to pilot scale.

Driving circularity: From plastics to bio-products

Alongside breakthroughs in food and energy, tackling one of the most persistent environmental challenges: plastics, is key to future low-carbon economic systems.

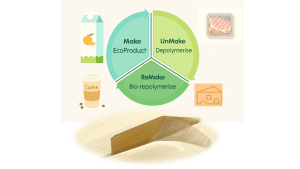

The Centre for Polymer Sustainability (CPS) is fast-tracking innovative technological solutions that replicate the self-sustaining cycles found in nature. Plastics are engineered to enter continuous make–unmake–remake loops, analogous to the regenerative processes in nature where plants are consumed and later decomposed to support new growth. Its pioneering work is transforming the lifecycle of plastics, redesigning materials to be recyclable by developing processes to break down existing plastics and creating pathways to reuse them in the same or new forms. Using a range of biomimetic approaches, CPS exploits untapped structure–property relationships in biopolymers to develop new eco-plastics which uniquely combine the high performance of conventional petro-plastics with a low carbon footprint and fully circular life cycles.

In collaboration with EU partners, by integrating advanced microbial and waste-stream fermentation, expert polymer processing, biodegradability, and closed-loop design, these eco-plastics have been developed to exhibit high oxygen and water barrier performance while avoiding the generation of microplastics. Post-use ready individual layer delamination facilitates their preparation as waste stream feedstocks for recycling and regeneration.

These eco-plastics represent a major step forward for sustainable food packaging compared to today’s high-barrier, fossil-based, non-biodegradable EVOH-laminate packaging.

By embedding circularity into polymer production, CPS complements other bioeconomy initiatives, developing low-carbon bio-based alternatives to fossil-based products, reducing waste, keeping it out of landfills and oceans.

At LIFE RI, the collaborative engines of research and innovation propel the bioeconomy. The successful establishment of the sector depends on integrated policy, research, industry and local community support, combined with sustained investment in innovation.

Clear goals for renewable resource use, circular production and climate action are demonstrated at Living Labs such as Mount Lucas in Co. Offaly, which are actively translating research into practice, showing how bio-based systems work in real settings. Pilot-scale facilities like the Irish Bioeconomy Foundation’s Bioprocess Plant and facilities such as the Centre for Applied Bioscience Research, LIFE RI and the Centre for Polymer Sustainability provide businesses, industries, healthcare services and marine and terrestrial farmers with access to cutting-edge technologies and expertise.

Equally, these facilities enable important community engagement and training, ensuring that stakeholders, aquaculture operators and enterprises can adopt new circular practices and share in the benefits, allowing the bioeconomy to take root.

Currently valued at €2.3tr, the European bioeconomy employs about 19 million people. Turning scientific ideas into thriving enterprises and industrial products that advance climate goals, create jobs and strengthen economic resilience is underpinned by a shared ethos: innovation must be circular, collaborative, and nature-positive.

Please Note: This is a Commercial Profile

This work is licensed under Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International.

Please note, this article will also appear in the 25th edition of our quarterly publication.