A sustainable, end-to-end approach to PFAS management.

PFAS are a large group of persistent synthetic chemicals widely used in industrial processes and consumer products. Their resistance to degradation has resulted in increasing contamination of drinking water, wastewater, groundwater, soil, and air emissions. As regulations tighten across Europe and globally, utilities and industrial operators face growing compliance, environmental, and reputational risks.

To address this challenge, an effective PFAS strategy must go beyond simple removal. A practical and sustainable approach follows three key stages: Search, Capture, and Destroy.

Understanding the PFAS challenge

Detecting and monitoring PFAS at very low concentrations remains technically complex. At the same time, legislation continues to evolve, with drinking water standards often advancing faster than those for wastewater and air emissions. Designing treatment systems to meet only today’s limits could be detrimentally short-sighted. Solutions should be future-proofed to address more stringent requirements ahead.

Activated carbon: Best available technique for PFAS removal

Activated carbon is widely recognised as a best available technique (BAT) for PFAS removal in both liquid and gas-phase applications. Its extremely high internal surface area and porous structure allow PFAS molecules to be effectively adsorbed from water and air streams.

Advanced, surface-modified granular activated carbons have been specifically developed by Puragen to improve PFAS capture. By optimising surface chemistry and pore structure, these carbons deliver higher removal efficiency, longer service life, and improved performance across a wide range of PFAS chain lengths, compared with standard GAC grades.

Flexible capture with mobile filtration

Mobile activated carbon filtration systems provide a fast, low-risk route to compliance. Designed as plug-and-play units, they eliminate the need for on-site carbon handling and are essentially CapEx-free, being supplied on a rental basis. Their modular and scalable design makes them ideal for temporary, emergency, or long-term installations across drinking water, wastewater, remediation, and industrial air treatment applications.

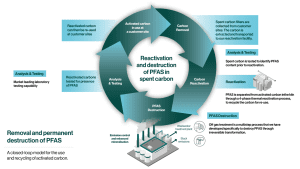

Closing the loop: PFAS destruction

True sustainability requires not only capturing PFAS but also permanently destroying them. Puragen’s advanced thermal reactivation process enables spent activated carbon to be recycled while completely breaking down PFAS molecules in a controlled, multi-stage process. This closed-loop approach prevents secondary emissions, reduces waste, and significantly lowers the carbon footprint compared with disposal or incineration. Separate facilities are available for ‘green list’ (drinking water/food) and ‘amber list’ (industrial/environmental) spent carbons.

Proven, future-proof solutions

An integrated Search, Capture, and Destroy strategy has been successfully applied across drinking water, wastewater, remediation, chemical, pharmaceutical, and other industrial sectors. By combining expert testing, advanced activated carbons, flexible filtration systems, and safe thermal reactivation, organisations can achieve reliable PFAS compliance today, while preparing for the regulations of tomorrow.

Please Note: This is a Commercial Profile

This work is licensed under Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International.