Electrostatic PFAS capture offers high-efficiency, low-waste, and cost-effective water treatment for long, short and ultra short chain compounds.

Per- and polyfluoroalkyl substances (PFAS) have become one of the most urgent challenges in environmental protection and regulatory compliance. These synthetic ‘forever chemicals’ are widely used in industrial processes and consumer products, ranging from firefighting foams and textiles to food packaging and electronics. But their stability, persistence, and bioaccumulative nature have led to widespread contamination, especially in landfill leachate, groundwater, and industrial wastewater.

PFAS compounds resist natural degradation and conventional water treatment, and their presence in drinking water, even at very low concentrations, has been linked to adverse health outcomes, including cancer, liver and immune system damage, and developmental effects. As a result, government agencies in the United States and around the world are setting increasingly stringent limits on PFAS concentrations in water, some now as low as four parts per trillion (ng/L) for individual compounds like PFOA and PFOS.

The treatment challenge

Conventional PFAS removal technologies such as granular activated carbon (GAC), ion exchange (IX), and reverse osmosis (RO) work moderately well for long-chain PFAS but perform poorly on short-chain variants. Moreover, these systems often generate PFAS-laden secondary waste streams – spent carbon, brine, or sludge – that present additional regulatory and cost burdens. As disposal options grow more restricted under the EPA’s Resource Conservation and Recovery Act (RCRA) proposals, the industry is urgently seeking more sustainable and cost-effective alternatives.

Enter BioLargo’s Aqueous Electrostatic Concentrator (AEC)

BioLargo Equipment, Solutions & Technologies, Inc. has developed a next-generation solution called the Aqueous Electrostatic Concentrator. This modular, membrane-based system uses electrokinetics to separate and concentrate PFAS compounds from water with industry-leading efficiency, minimal waste generation, and a compelling lifecycle cost advantage.

The AEC works by exploiting the anionic charge of PFAS molecules. As contaminated water passes through the treatment chamber, a controlled electrostatic field pulls PFAS across a selective membrane and binds them to the surface. Non-target ions and neutral molecules pass through the system, while PFAS are immobilised and later removed. The system requires no chemical additives, no backwash cycles, and no complicated pre-treatment chemistry.

Key features of the AEC process include:

• 2-30-second residence time per stage

• Real-time conductivity monitoring for adaptive voltage optimisation

• No interference from salinity or suspended solids

• Low energy use and chemical demand

• Continuous PFAS removal monitoring

Demonstrated performance across applications

The AEC has been tested at both bench scale and in field pilot projects on a variety of PFAS-laden water types, including:

• Raw landfill leachate

• Post-ultrafiltration (UF) leachate

• Municipal wastewater

• Foamate from PFAS foam fractionation

• Reverse osmosis concentrate

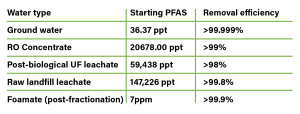

Independent third-party validation from SGS and the University of Tennessee confirmed that the system delivers >99% PFAS removal in a single pass for most compounds. Multiple stages can be sequenced to achieve reductions below detection limits, with consistent removal of both long- and short-chain compounds, including PFOA, PFOS, PFNA, PFBA, GenX, PFHxA and PFHxS.

A few key examples:

The results confirm that AEC is suitable both as a primary treatment solution and as a polishing step after other methods, offering a versatile and scalable approach for a range of treatment scenarios.

Low waste profile, high regulatory readiness

AEC stands apart from legacy treatment systems through its ultra-low waste generation. The only significant waste component is the PFAS-binding membrane itself, which is designed to last 1–3 years, depending on use and can be thermally or electrochemically destroyed. Unlike GAC or IX, AEC does not create contaminated brine or require hazardous media regeneration.

AEC residuals are compatible with EPA-aligned destruction methods, including hydrothermal alkaline treatment and electrooxidation. This positions AEC as a forward-compatible solution in anticipation of RCRA hazardous waste classification for PFAS, a likely outcome of EPA’s regulatory roadmap.

Lifecycle cost advantage

For utilities, landfills, and industrial users, cost is often the limiting factor for full-scale PFAS remediation. This is where AEC delivers one of its most compelling advantages.

- Capital costs: $2.5m–$4.0m (scalable)

- Operating costs: ~$100–$150/day or ~$31,000 annually

- Energy and chemical use: Minimal

The reduction in waste disposal costs and elimination of PFAS-laden brine contribute to total lifecycle savings of up to 80% over incumbent technologies.

A future-proof PFAS treatment platform

To ensure peace of mind and proper treatment, BioLargo Equipment has partnered with Verralize, an innovator of next-generation water testing technologies, to alpha test their ‘lab-on-a-sensor’ field test kits capable of rapid, on-site detection of per- and polyfluoroalkyl substances (PFAS). These kits will allow customers the ability to test for PFAS in the treated effluent, ensuring the system is working properly without the long laboratory wait times. This ten-minute test is expected to give a specific result with quantitative results between 1.5 ppt and 20 ppt.

BioLargo’s AEC solution represents a paradigm shift in PFAS water treatment:

• It efficiently removes all PFAS chain lengths.

• It produces virtually no hazardous waste.

• It integrates with destruction pathways for full compliance.

• It allows for continuous monitoring, along with a verification field test

• And it does all this at a fraction of the cost of traditional technologies.

As regulatory pressures intensify and public concern grows, scalable and sustainable PFAS solutions will become essential infrastructure. BioLargo’s AEC offers a field-proven, adaptable platform ready to meet that challenge.

For technical specifications, site-specific modelling, or pilot testing inquiries, contact: pfas@biolargo.com

Please note, this article will also appear in the 23rd edition of our quarterly publication.