Helios Innovations’ technology is proven to separate and concentrate PFAS from extremely contaminated industrial waste streams, including AFFF above 20 million ng/L.

PFAS contamination is discussed widely today, particularly in the context of drinking water, groundwater protection, wastewater treatment, and human exposure. However, the streams that receive most public attention are not the ones where the technical bottleneck exists. PFAS found in municipal water, surface water, or leachate are typically present at concentrations in the range of 100–15,000 ng/L. These levels are difficult from a regulatory and health perspective, but they are not what challenge the limits of available technology.

Industrial PFAS streams are fundamentally different. They originate from firefighting foams, discharge testing of fixed fire suppression systems, emergency response operations, extinguishers, and process waste handled in industry and defence. These streams do not contain trace levels of PFAS contamination. Instead, they can reach levels of millions to tens of millions of nanograms per litre. In many cases, discarded aqueous film-forming foam (AFFF) contains two factors: very high PFAS concentrations and surfactant-driven foam behaviour that makes treatment significantly more difficult.

This category of PFAS waste has historically lacked both ownership and a technical pathway. Regulations existed for environmental protection, but there were limited instructions for handling the waste once collected. As a result, temporary storage, ad-hoc handling, and long-distance transport for destruction became the default approach. Not because the industry wanted it that way, but because there was no realistic alternative.

Today, this gap is no longer acceptable. The phase-out of AFFF is accelerating globally, and industries are left with stockpiles of used and discarded foam that must be managed responsibly. Without a scalable handling approach, regulators, waste processors, and industry face the risk that PFAS remains in unsuitable long-term storage, is mishandled to avoid extremely costly destruction, or is transported across regions without a clear processing pathway.

The treatment gap: Why existing technologies do not work here

The majority of PFAS treatment systems on the market have been developed for low-to-moderate concentrations. These systems, including granular activated carbon, ion exchange, reverse osmosis, and emerging adsorption media, can be technically effective when PFAS levels remain below approximately 50,000 ng/L. Some advanced systems demonstrate possible removal at higher concentrations, but at these extremes, the economics generally break down.

When exposed to highly contaminated AFFF waste streams, filter materials saturate rapidly. Membranes foul. Media must be replaced continuously. Biological and electrochemical systems lose stability, and adsorption approaches are often orders of magnitude too costly to operate.

At the same time, destruction-only pathways exist, but they do not solve the upstream bottleneck. High-temperature incineration remains the only approved route for destroying PFAS at scale in many regions. However, without separation, industry must transport and destroy large volumes of water, not contaminants. This creates a cost structure that is incompatible with implementation at scale.

The result is a major mismatch: the highest-risk PFAS streams are the least suitable for the available technologies designed for lower concentrations.

Helios Innovations operates in this gap.

We focus on where the PFAS concentration is too high for existing solutions.

Introducing Helios Innovations

Helios Innovations is a Swedish industrial water technology company focused on handling the most challenging liquid waste streams. PFAS is one of several strategic areas — alongside emulsions, chemical residues, slurries, metal-containing fluids, adhesives, and complex wastewater streams — where conventional treatment becomes technically or economically unworkable.

Our solution is not a pilot or a laboratory concept. It is a commercially operated system deployed in industrial environments and running continuously under real-world conditions.

Our first PFAS pilots began in 2023. The first full-scale industrial unit handling discarded AFFF was commissioned in 2024. Today, the solution is used commercially by major fire protection and industrial stakeholders across Sweden and Norway.

To date, more than 1,600m3 of highly contaminated PFAS waste streams have been processed using our systems.

The technology: Evaporative separation built for industrial reality

Evaporation is a known separation principle, but not all evaporation technologies are suitable for this category of waste. Most evaporators are designed for relatively clean process streams. When exposed to waste streams containing oils, surfactants, polymers, or foam-forming chemicals like AFFF, traditional evaporators tend to foul, scale, collapse in performance, or require very frequent shutdowns for cleaning.

Our system is not a traditional evaporator. Helios’ approach combines controlled low-temperature, closed system evaporation at atmospheric pressure with proprietary recirculation strategies, process stabilisation, and integrated anti-foaming mechanisms. The system is engineered to remain stable even when exposed to rapidly changing compositions, high suspended solids content, and severe foaming behaviour. This enables continuous operation on waste streams previously considered impossible to evaporate at scale.

The outcome is straightforward: the water is separated from the contamination. PFAS remains in a concentrated residual stream. The clean distillate can be further treated or discharged depending on local requirements and approvals.

Built for real-world operation, not lab-scale demonstration.

Proven commercial deployment

Since 2024, Helios has continuously treated used and discarded AFFF waste streams from fire protection companies, industrial safety departments, waste service providers, and municipal handling chains across Sweden and Norway.

Approximately 70% of Sweden’s recovered AFFF waste streams and roughly 60% of Norway’s recovered material now pass through a Helios separation process prior to destruction. This includes material from fixed fire suppression system testing, extinguishers, spill collection, legacy stock management, and emergency response operations.

The system consistently achieves PFAS separation efficiencies exceeding 98% on chain lengths >3 carbons, even with input concentrations exceeding 20 million nanograms per litre.

The CONTESS platform: Treatment at the source

To make industrial PFAS handling practical, the technology must be deployable, not just technically effective. The CONTESS was developed for that purpose: a modular plug-and-play unit that treats hazardous process water directly onsite with a small footprint, without requiring capital investment or specialised operational staffing.

Each unit is delivered as a service, including installation, monitoring, and management of the concentrated waste stream. The customer pays per treated volume, while benefiting from reduced transport, lower destruction cost, and greater control of compliance handling.

CONTESS units operate continuously and autonomously, and have a capacity of 1,000 cubic meters per year, with remote supervision and process stability control. It is suited not only to discarded AFFF streams, but also to emulsions, metalworking fluids, wash water, and other complex industrial liquids.

By standardising form factor and delivery model, the CONTESS enables scalable deployment, supporting a transition from temporary storage and long-distance transport to controlled treatment at the source.

Case study: Washing liquid from AFFF manufacturing, mass reduction, and circular water reuse

A manufacturing facility producing fire-suppressant foam struggled with contaminated washing liquid that had previously been sent for high-temperature incineration at a high cost. Their washing liquid, after foam production and equipment washing, contained high concentrations of PFAS and could not be treated with conventional methods. Every drop of that water had to be transported off-site for incineration — a costly, carbon-intensive process.

In 2025, the facility commissioned Helios’ evaporation technology on site. Waste volume to destruction reduced by roughly 90%. Where previously 100% of the wastewater was destroyed, now only 10% remains in the concentrated residue. Scope-3 CO₂ emissions reduced by about 16 tons per year due to less transport and lower destruction volume. The unit operates continuously under industrial conditions with automated monitoring.

This example demonstrates how previously waste-heavy water streams from foam production can be transformed into a manageable flow. The result: lower cost, reduced environmental footprint, and a large cut in transported and destroyed volume. For segments of industry facing similar challenges, this model offers a scalable and realistic alternative to the default incineration of entire water volumes.

Why concentration enables scalable destruction

Today, the limiting factor is not incineration capacity itself. It is the volume entering the destruction chain.

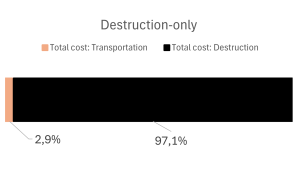

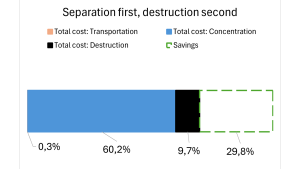

When high PFAS waste is handled without a separation step, transport and destruction costs apply to the entire volume. Since most AFFF waste streams are more than 95% water, the majority of the cost today is associated with transporting and destroying water.

Concentrating the PFAS dramatically changes the equation. By transforming large volumes of AFFF waste into a small, highly concentrated PFAS fraction, destruction becomes dramatically cheaper and operationally feasible. The volume needed to be destructed is lowered by a factor of 10 to 30, depending on the composition and moisture level of the waste stream.

In Sweden, there is currently only one facility receiving highly concentrated PFAS waste for destruction. Even in this constrained system, concentration radically improves feasibility because transport volumes decrease while environmental compliance remains intact.

The same model applies across Europe, where PFAS contamination exists in many regions but destruction capacity is centralised or limited. In some cases, large industrial sites may eventually generate enough concentrated material to support on-site destruction; however, for most organisations, separation and concentration will remain essential to enabling the destruction chain.

Separation first, destruction second, is the only scalable industrial PFAS handling model.

Looking ahead: From PFAS to the broader hazardous waste challenge

PFAS handling is one of the clearest examples of the need for scalable separation and concentration infrastructure, but it is not the only one. The same platform used for PFAS is deployed on emulsions, slurries, oil-containing waste, chemical residues, and other complex wastewaters where transport, treatment, or destruction becomes prohibitively expensive.

The long-term objective is the same across all waste categories: reduce volume, stabilise handling, and enable pathways for reuse, recycling, or destruction depending on the material.

As regulations tighten and industries shift toward traceability, mass balance, and circular responsibility, the ability to separate contaminants at source becomes increasingly strategic.

Call to action

Industrial PFAS handling cannot rely solely on regulation or long-term storage. The world needs clear deployment pathways, transparent mass balance, and cooperation between separation and destruction technologies. The discussion must now move from problem definition to implementation.

We are past the question of whether extreme PFAS waste can be treated. The remaining work is scaling access so it becomes standard practice, not an exception.