Proteum Energy’s revolutionary SnMR™ hydrogen production technology creates a clean energy addition.

Gas flaring is an environmental issue of major importance. It is the process of burning excess gases during oil and gas production, contributing a staggering 350 million tons of carbon equivalent annually.

Proteum Energy began its business in 2014 with the environmental mission of mitigating gas flaring in oil and gas production by designing and producing a patented modular flare gas remediation skid. By 2018, the skid was placed into commercial use in the Permian Basin in Texas.

Since then, hydrogen has emerged as a promising and scalable solution to the environmental problems resulting from climate change. These are caused not only by gas flaring, but massive global CO2 and greenhouse gas emissions as well.

With the onset of the hydrogen economy in 2020, Proteum Energy strategically decided to focus on its role in contributing to the lowering of greenhouse gases by producing low-carbon intensity renewable hydrogen and renewable natural gas (RNG) from ethanol.

The company’s first project in central California will produce enough transportation fuel cell hydrogen in one year to offset the CO2 emissions impact of approximately 31,000,000 gallons of diesel fuel that would otherwise be consumed in heavy-duty transportation.

This eBook will highlight Proteum Energy’s goal to reduce CO2 greenhouse gas emissions and combat climate change with low-cost, low-carbon intensity hydrogen and RNG production.

It will outline the dramatic challenges associated with greenhouse gases and global warming. The eBook will then go on to showcase Proteum Energy’s SnMR™ hydrogen production technology versus other methods.

What are some of the primary problems caused by climate change?

Climate change is significantly affecting the globe in a variety of ways, including:

Rising temperatures

Global warming is causing an increase in average temperatures, leading to heatwaves, heat-related illnesses, and heat-related deaths.

It also disrupts natural weather patterns and impacts agriculture, water availability, and natural habitats.

Extreme weather events

Climate change intensifies extreme weather phenomena such as hurricanes, cyclones, droughts, floods, and wildfires.

These events can cause significant destruction, displacement of communities, infrastructure damage, economic losses, and loss of human lives.

Sea levels rise

As the Earth’s temperature rises, glaciers and polar ice caps melt, causing sea levels to rise. This threatens coastal areas, low-lying islands, and densely populated cities, increasing the risk of coastal erosion, flooding, and saltwater intrusion into freshwater sources.

Ecosystem disruptions

Climate change disrupts ecosystems by altering precipitation patterns, temperature regimes, and habitats. This leads to species extinction, shifts in species distribution, disruptions in migration patterns, and the loss of biodiversity.

It can also impact ecosystems’ ability to provide essential services, such as food production, water purification, and carbon storage.

Water scarcity

Changing precipitation patterns and increased evaporation due to higher temperatures result in water scarcity in many regions. This affects agriculture, access to clean drinking water, sanitation, and hygiene, potentially leading to conflicts over water resources.

Negative impacts on agriculture

Climate change affects agricultural productivity by altering rainfall patterns, causing droughts, floods, and changing pest/disease dynamics. These impacts can lead to crop failures, reduced yields, food insecurity, and increased food prices.

Public health risks

Climate change is associated with various public health risks. These include increased vector-borne diseases like malaria and dengue fever, heat-related illnesses and deaths, respiratory problems due to air pollution, and waterborne diseases due to compromised water quality and availability.

Economic consequences

The consequences of climate change carry significant economic costs. These costs result from damage to infrastructure and property, health-related expenses, agricultural losses, the need for adaptation measures, and human migration due to environmental circumstances.

It’s important to note that these problems interrelate and exacerbate each other, making climate change a global challenge that requires collective action and mitigation efforts.

The next section is a description of just one solution. The overall solution is enormous. But the problem can be solved by lots of one-by-one efforts.

Hydrogen from ethanol: One solution

In the face of climate change, the search for clean, sustainable, and reliable energy sources has never been more critical.

Proteum Energy reviewed its business offering and renewable hydrogen from ethanol became the central solution for making the most impact in the world. Thereby the team leveraged its flare gas intellectual property to focus on hydrogen and RNG.

Hydrogen from ethanol is a feasible and attractive solution due to ethanol’s unique properties and potential for large-scale implementation.

Constituting approximately 75% of the elemental mass of the Universe, hydrogen’s use as an energy carrier provides an opportunity for sustainable energy development.

What are the advantages of using hydrogen as an energy carrier?

Hydrogen holds a variety of benefits over other energy sources, including:

Zero emissions

As hydrogen fuel is combusted, it generates water vapour instead of carbon dioxide, a primary greenhouse gas. This property makes hydrogen a zero-emission fuel, aligning with global efforts to mitigate climate change.

Renewable energy storage with ethanol

Pairing hydrogen with renewable energy sources such as ethanol can help overcome the challenge of intermittent supply. This renewable fuel can be derived from corn, grains, sugar cane, and many cellulosic sources.

The plants sequester CO2 from the atmosphere and stored hydrogen can be captured in the form of a sugar-based alcohol during fermentation and released during the reformation process.

CO2 is further captured during the reformation and sequestered underground.

Versatility

The produced hydrogen can be liquified for fuel cell electric vehicles for heavy-duty transportation, used in hydro-treating many renewable fuels like SAF, or directly injected into pipelines.

Hydrogen’s utilisation in various sectors, including transportation, electricity, ammonia production, and many industrial processes, adds to its practical and environmental appeal.

The challenges of using hydrogen as a fuel and Proteum Energy’s solution

Despite the benefits, the use of hydrogen as a transportation fuel presents several challenges, primarily related to its production, storage, and transportation.

It’s also crucial to ensure hydrogen’s production is genuinely clean, as currently, most commercial hydrogen is derived from natural gas with steam methane reforming (SMR) requiring higher energy than SnMR™ and producing more CO2.

Clean hydrogen

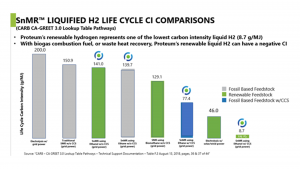

Today, most hydrogen production is derived from fossil fuels, resulting in carbon dioxide emissions being released into the atmosphere.

However, the renewable pathway, using ethanol with carbon sequestration can result in negative carbon intensity, meaning CO2 is literally removed from the atmosphere.

Proteum Energy, coming from an oil and gas solutions background, patented a fossil fuel hydrogen production technology called Steam non-Methane Reforming (SnMR™) and began reforming flare and associated gas.

The Proteum Energy team wanted a renewable option for hydrogen production. In 2021, Proteum reviewed ethanol as a feasible renewable fuel that could be readily produced, easily stored, and transported.

Storage and transportation

Storing and transporting hydrogen, due to its low energy density, is more complex than traditional fuels. Research is underway to develop advanced storage methods and robust infrastructure that can effectively deal with these challenges.

Ethanol solved many of these problems.

Proteum Energy’s patented platform technology allows abundant renewable hydrogen to be produced, or the potential for carbon-negative liquified hydrogen with CCS.

The technology enables hydrogen to be produced anywhere there is an ethanol production facility or ethanol transloading outlet.

Economic viability

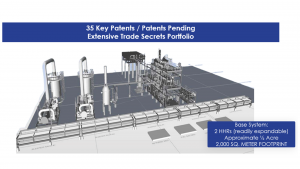

Proteum Energy’s modular and scalable SnMR™ hydrogen production technology is a platform that can be shop built in truckable modules, lowering the overall cost of CAPEX per kg of hydrogen produced.

Proteum Energy’s SnMR™ plant: A practical shell and tube reactor design

One of the benefits of coming from an oil and gas processing background is the ability to look at tried and true shell and tube reactor technologies. The reasons for this are detailed as follows:

Design and operation safety

In the design phase of shell and tube reactors, safety is a pivotal concern. They are built to endure high pressures and temperatures while maintaining structural integrity.

For instance, the thickness of tubes is designed to prevent rupturing. Material selection is typically based on the corrosiveness of the gas to prevent degradation over time.1

In operation, safety measures include regular monitoring and maintenance. The presence of pressure relief valves ensures that any overpressure situation can be managed effectively.2

Reliability and performance

Shell and tube reactors are known for their reliability. They exhibit a high degree of resistance against fouling, allowing for extended operation with minimal maintenance.3

These reactors offer flexible performance, catering to different pressure and temperature ranges. They can cope with abrupt changes with minimal degradation in performance.

Crucial operational aspects such as flow rate, heat transfer, and pressure drops are monitored routinely to ensure reliability.1

Limitations and failures

Despite the robustness of shell and tube reactors, they are susceptible to certain failures. Common ones include tube leakage due to material failure or fouling. Overheating may also lead to the deformation or bursting of tubes. Regular monitoring and maintenance are crucial in preventing such failures.4

Proteum Energy chose a shell and tube reactor design for hydrogen production because of their carefully engineered design, inherent flexibility, and high resistance to fouling. This makes Proteum’s shell and tube reactors a reliable and safe choice for gas processing.

Of course, Proteum must ensure optimal operation, regular monitoring, maintenance, and adherence to safety measures.

SnMR™ versus SMR

Among the different methods of hydrogen production, SMR is the most well-known and commercially established process. Proteum Energy’s SnMR™ hydrogen production process is similar to SMR with several more benefits.

SnMR™ is a catalytic process that involves the conversion of non-methane and oxygenated hydrocarbons (like ethanol) into hydrogen (H2), trace amounts of carbon monoxide (CO), and carbon dioxide (CO2) through a lower temperature reaction than typical SMR.

Characteristics of SnMR™

SnMR™ hydrogen production presents a wide range of advantages, such as:

High efficiency

SnMR™, like SMR is known for its high hydrogen production efficiency. The process’ exothermicity is often utilised by capturing heat and using it for co-generation or process heating, enhancing overall efficiency.

Scalability

SnMR™, like SMR is a highly scalable process, making it suitable for various production capacities.

It can be implemented in small-scale distributed applications or large-scale centralised hydrogen production facilities.

Cost-effectiveness

SnMR™ is economically advantageous due to its utilisation of abundant and relatively low-cost feedstocks, i.e., rejected ethane, associated gases, and hydrous cuts of ethanol.

This makes SnMR™ one of the most cost-effective methods of hydrogen production, especially when compared to alternative processes like electrolysis.

Infrastructure compatibility

The existing infrastructure for natural gas distribution and storage can be utilised for SnMR™-based hydrogen production. Leveraging this infrastructure can facilitate a smoother transition to a hydrogen-based economy.

Carbon emissions

SnMR™ has CO2 emissions as a byproduct, mainly attributed to the equilibrium reactions in the system.

CO2 emissions are primarily sequestered, but they are biogenic in nature with ethanol and can be mitigated through various carbon capture and storage (CCS) technologies or by implementing more advanced utilisation and reforming techniques such as e-methanol production.

Catalysts and reaction conditions

The choice of catalyst, reaction temperature, and pressure significantly impact the efficiency and selectivity of SnMR™.

Ongoing research with the University of Regina CETRI centre focuses on developing improved catalysts and optimising reaction conditions to enhance the process’ performance and reduce its environmental impact.

Co-production of other chemicals

SnMR™ not only produces hydrogen but also generates valuable by-products like RNG.

This finds attractive RNG sales applications in many regions in the US where there are active Book and Claim transactions.

Conclusion

The Proteum Energy SnMR™ process has been built on a foundation of decades-proven shell and tube reactor designs. SnMR™ is a lower energy reformation process than traditional SMR for hydrogen production and it is modular, truckable, and shop built by design.

The system is a platform and is scalable for larger-sized hydrogen production requirements. It can be utilised with non-Methane renewable hydrocarbon fuels to produce hydrogen, RNG, and CO2.