FREDsense Technologies’ innovative FRED-PFAS solution is transforming PFAS detection, delivering results in near real time.

Per- and polyfluoroalkyl substances (PFAS) have emerged as one of the most persistent environmental challenges of the 21st century. These ‘forever chemicals’ are found in thousands of industrial and consumer products, from firefighting foams to non-stick cookware. Their resilience in the environment and potential health impacts have made detecting and managing PFAS contamination a high priority for regulators, industry, and communities alike.

FREDsense Technologies Corp. has developed a transformative solution to this problem with its FRED-PFAS™ Field Kit – a portable, rapid analysis platform that is disrupting traditional PFAS monitoring approaches. With the ability to provide on-site, same-day PFAS concentration results, the FRED-PFAS Kit offers unparalleled agility for decision-makers in the field.

Limitations of lab analysis

For decades, PFAS detection has depended almost exclusively on centralised laboratory analysis. While lab-based methods like LC-MS/MS (liquid chromatography–mass spectrometry) are accurate and reliable, they come with significant limitations, particularly when real-time decisions are needed.

Delayed results

Standard laboratory turnaround times for PFAS results typically range from 10-20 business days, depending on location, backlog, and analysis complexity. For projects that require PFAS results to make critical decisions, such as site investigations, environmental remediation, and spill response, this delay can be costly and disruptive.

Logistical complexity

Transporting samples to certified labs involves a meticulous chain of custody, specialised containers, and temperature-controlled conditions. Field crews must often halt work while waiting for data to return, leading to increased costs and lost productivity.

Limited sample frequency

Because lab testing can be expensive when rush fees are applied, sampling campaigns are often constrained by budget, meaning fewer samples, longer intervals between data points, and less dynamic site understanding. This can result in missed contamination plumes or ineffective remediation strategies.

Inefficient iteration

When pilot testing treatment technologies or performing optimisation studies, lab delays create a bottleneck. Without immediate feedback, it’s impossible to adjust strategies quickly. This trial-and-error process stretches projects out over weeks or months longer than necessary.

Real-time analysis with FRED-PFAS

FREDsense’s FRED-PFAS Field Kit directly addresses these challenges by providing same-day PFAS detection capabilities – right where the work is happening. Built on FREDsense’s biology-inspired chemical platform, the kit uses engineered chemistries to generate a measurable fluorescence signal in the presence of certain common PFAS compounds.

Key features of the FRED-PFAS Kit

• Rapid turnaround: Results are delivered in approximately three to four hours from sample collection to output. Multiple samples can be done in tandem, and sampling steps can be triaged to maximise daily outputs for each FRED-PFAS system.

- On-site analysis: No need to ship samples. Technicians can run the test at the sampling location.

- Minimal infrastructure: The system is portable and designed for rugged field conditions with minimal power or lab support.

By enabling near real-time results, FRED-PFAS turns PFAS data into an actionable tool – allowing environmental professionals and operators to react immediately, rather than retroactively.

What does FRED-PFAS measure?

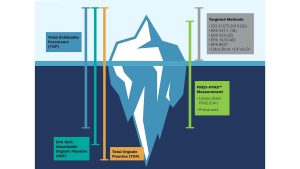

FRED-PFAS outputs a Total PFAS screening measurement, which captures many regulated long-chain (C5+) PFAS compounds such as PFOA and PFOS, and certain common precursors. Its limit of detection is currently 1,000 ppt (ng/L), with dedicated commitments to lower detection limits in future versions of the system.

Real-world applications

FRED-PFAS has been deployed across a variety of projects – from remediation trials to infrastructure assessments – demonstrating its versatility and real-world value.

Remediation pilots

Environmental consultants and technology providers use the kit during PFAS treatment pilot studies to monitor influent and effluent concentrations. This enables rapid optimisation of treatment media, flow rates, and regeneration cycles – without waiting for lab data. One recent pilot with WSP and its PFASERTM showed that real-time monitoring with FRED-PFAS had the potential to reduce the total project site visits by 60%, translating into significant cost savings.

AFFF transitions

When changing out aqueous film-forming foams (AFFF) for low-PFAS alternatives, FRED-PFAS is used to screen rinse cycles for contamination. FRED-PFAS data correlates closely with lab methods for these types of projects, as shown in a project with TRS Group. These transitions can be costly for facility owners dealing with fire suppression system rentals, refurbishments, and cleanouts. Same-day PFAS detection can accelerate project timelines and get systems back online faster, unlocking significant savings.

Source identification

In situations where the source of PFAS is unclear – such as industrial parks, landfills, or fire training grounds – the FRED-PFAS kit enables high-density sampling campaigns. Teams can collect and analyse samples across a wide area in a single day, identifying hotspots without multiple lab submissions or site revisits.

Field screening for research

Academic researchers and NGOs investigating PFAS fate and transport in novel ecosystems use FRED-PFAS as a tool to collect preliminary data quickly. This is especially valuable in remote or hard-to-access locations where transporting samples is difficult.

Impact of real-time analysis on projects

The introduction of real-time PFAS screening is fundamentally shifting how environmental projects are planned and executed.

Agility and responsiveness

With on-site results, field teams can adapt in real time – sampling new locations, adjusting treatment strategies, or escalating concerns as needed. This agility shortens project timelines and improves outcomes.

Increased sampling density

Because each test is faster and more cost-effective, organisations can afford to take more samples. This leads to higher-resolution data, better decision-making in the field, and more targeted remediation strategies.

Enhanced stakeholder confidence

Communities, regulators, and investors want to see that projects are progressing with urgency and transparency. Demonstrating that PFAS is being monitored in real time shows a commitment to proactive environmental stewardship.

Reduced project costs

Time is money. By accelerating decision-making and shortening project lifecycles, FRED-PFAS delivers a direct return on investment. Whether it’s fewer days in the field, lower analytical fees, or reduced treatment trial duration, the savings can be substantial.

Support for technology development

Innovators in PFAS treatment technologies face a tough road to scale-up. Real-time monitoring allows them to iterate faster, validate performance under real-world conditions, and bring their solutions to market more efficiently.

Get in touch

FREDsense Technologies is on a mission to simplify and accelerate water quality monitoring through advanced sensor technologies. If you’re facing PFAS challenges – whether in drinking water, wastewater, remediation, or research – FREDsense is ready to help.

Please note, this article will also appear in the 23rd edition of our quarterly publication.