How a sustainable, scalable nanomaterial is reshaping the future of food-safe packaging.

For decades, plastic and PFAS-based coatings have served as the invisible armour in food packaging, delivering critical protection against moisture, oil, and air. But these materials are now under intense global scrutiny for their environmental persistence and links to human health risks. Known as ‘forever chemicals’, PFAS do not degrade naturally, accumulate in the body, and are increasingly tied to cancer, immune dysfunction, and infertility.

With new legislation coming into effect – including the U.S. Environmental Protection Agency’s (EPA) implementation of the Toxic Substances Control Act (TSCA) and EU-wide restrictions – governments, manufacturers, and researchers face a shared imperative: to eliminate PFAS and harmful plastics from food-contact materials.

But the central question remains: what can replace them?

GO-Eco, a groundbreaking graphene-oxide-based solution created in partnership with Chang Robotics and Northwestern University, may finally provide a practical solution.

The challenge: Eliminating PFAS without sacrificing performance

Plastics and PFAS weren’t adopted by accident. They are effective, low-cost materials that provide unmatched barrier performance, keeping food safe by repelling moisture, oils, and gases. They also enhance durability and shelf life, both of which are critical in global food supply chains.

However, their properties make them nearly impossible to recycle and become toxic over time. As environmental regulations tighten, demand is growing for alternatives that are:

- Food-safe;

- Biodegradable or recyclable;

- Cost-effective;

- Commercially scalable; and

- Just as functional.

To date, most alternatives fall short. Biopolymers, although compostable, are often expensive and require additional lamination to enhance their durability. Other coatings lack the same level of water or oil resistance, or they degrade package strength.

The breakthrough: GO-Eco and the power of graphene oxide

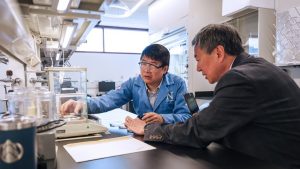

GO-Eco™ is a first-of-its-kind solution that uses graphene oxide (GO) as a multifunctional, environmentally friendly barrier. Developed by scientists at Northwestern University, Professors SonBinh Nguyen and Timothy Wei, and commercialised through Chang Robotics, GO-Eco represents a significant advancement in materials science.

What makes GO different?

Graphene oxide is a carbon-based nanomaterial made of atom-thin sheets in a hexagonal matrix, enriched with oxygen and hydroxyl ions. When exfoliated into individual sheets, GO firmly bonds to paper fibres, forming a high-performance barrier against liquids, oils, and gases while significantly increasing strength.

The result: a reinforced, non-toxic paper that blocks water, oils, and gas while allowing the package to remain recyclable, compostable, and biodegradable.

Lab-verified performance: Outperforming PFAS and plastic coatings

GO-Eco’s effectiveness isn’t theoretical – it’s been independently verified through rigorous testing.

In early 2025, researchers at Western Michigan University’s Paper Pilot Plant conducted two major studies comparing GO-Eco to commercial barrier coatings using industry-standard metrics. Key findings include:

- Superior water resistance: GO-Eco-treated paper absorbed 40% less water than paper treated with a conventional water barrier.

- Extended oil repellency: GO-Eco-treated sheets withstood oil absorption significantly longer, delaying penetration far beyond industry alternatives.

- Stronger packaging: GO-Eco increased tensile strength by 27% and burst strength by 56%, making the packaging not only safer but also more durable and reliable.

- Near-zero waste and full integration: Nearly 100% of GO binds to pulp fibres, ensuring minimal runoff and preventing food contamination. Unlike PFAS coatings, which can leach or flake, GO-Eco becomes an integral part of the paper matrix itself.

These results confirm GO-Eco’s capability to match and exceed PFAS performance without the health and environmental consequences.

Real-world momentum: Industry pilots and commercial validation

Although still in its early stages of commercialisation, GO-Eco has already achieved significant market traction.

As of July 2025:

- 15+ organisations have signed mutual NDAs with GO-Eco.

- 10+ companies are actively testing GO-Eco samples.

- Three companies are preparing pilot-scale production trials set for late July and early August 2025.

Partners include major players across moulded fibre packaging, quick-service restaurant packaging, food-grade paperboard, and sustainable tableware. These companies are now evaluating GO-Eco for broad integration into existing supply chains and product lines.

GO-Eco connects scientific credibility with practical industry use, bridging the gap between lab achievements and real-world deployment.

Mission-driven innovation

At the heart of GO-Eco’s development is a desire to align material science with public health.

Dr Philip Kuriakose, Hematologist and Oncologist at Henry Ford Health, said: “PFAS are absorbed in our bodies, and they don’t degrade easily, so there’s a risk of cumulative toxicity. That’s why they’re called ‘forever chemicals’.”

GO-Eco offers an alternative that’s not just scientifically sound, but ethically necessary, enabling industries to protect consumers without compromising sustainability.

Conclusion: The future of food-safe packaging is here

The need for PFAS-free packaging is no longer just an environmental goal – it’s a regulatory requirement, a public health priority, and a global market demand.

GO-Eco delivers a rare combination of performance, scalability, affordability, and safety. With validated results, growing commercial traction, and strong IP protections, GO-Eco stands out as one of the most viable next-generation solutions for PFAS-free packaging globally.

Whether you’re a packaging supplier, food brand, retailer, or regulator, the opportunity to lead is now.

To learn more or explore partnership opportunities, visit go-eco.solutions.

Please note, this article will also appear in the 23rd edition of our quarterly publication.

Get The Latest PFAS News

Explore the latest PFAS news, updates on PFAS contamination, health risks, regulations, and environmental impact. Visit our comprehensive PFAS news archive to stay informed with in-depth reporting, expert analysis, and breaking developments. Start reading now to stay ahead on all things PFAS and ‘forever chemicals’.