Destruction. Redefined. PERSES ends PFAS waste. General Atomics’ system is proven to eliminate toxic waste with 99.99%+ efficiency, leaving only clean byproducts.

Developed by General Atomics Electromagnetic Systems (GA-EMS) and named after the Greek titan of destruction, PERSES is a decisive response to a variety of problematic organic wastes, including one of the world’s most persistent pollutants: PFAS (per- and polyfluoroalkyl substances). These synthetic chemicals, more than 12,000 in total, are used in aerospace, defence, automotive, construction, firefighting, electronics, and everyday products like nonstick cookware, carpets, and water-resistant clothing.

Often called ‘forever chemicals,’ PFAS do not break down naturally. Instead, they accumulate in soil, water, and the human body, where they’ve been linked to serious health risks including hormone disruption, immune system damage, and certain cancers.

Traditional methods of handling PFAS waste, such as landfilling, incineration, deep-well injection, filtration, and long-term storage, have systemic issues. Some of these approaches don’t eliminate PFAS; they simply move them. Others create environmental hazards, face siting constraints, or carry long-term costs. For example, filters and resin beads used to trap PFAS eventually become hazardous waste themselves, requiring further treatment and disposal.

As awareness of PFAS-related risks grows and bans on outdated disposal methods expand, federal, state, and local agencies are urgently seeking a permanent solution to end the cycle of contamination.

Enter PERSES: Titan-forged technology for PFAS destruction

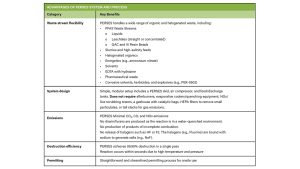

GA-EMS’ PERSES is a commercially available, field-proven system that uses industrial Supercritical Water Oxidation (iSCWO) to destroy PFAS and other hazardous organic waste at the molecular level. The process combines contaminated materials with water and air inside a high-pressure reactor operating at temperatures up to 700°C (1,292°F) and pressures up to 4,000 psi. Under these extreme conditions, water enters a supercritical state – behaving like both a liquid and a gas. This allows for complete oxidation of PFAS and co-contaminants in a single pass.

The result is 99.99% or greater destruction efficiency, with only clean water, benign salts, and carbon dioxide left behind. There’s no need for post-treatment, no toxic residue, and no complex off-gas systems. PERSES delivers verified elimination down to non-detect levels —no containment, no residuals.

Validated by the EPA

While Supercritical Water Oxidation has existed for decades, it wasn’t always considered viable for industrial-scale use. That changed in the 1990s when GA-EMS developed an advanced SCWO system for US government applications. By 2012, the company began commercial sales of PERSES (previously known as iSCWO) systems in the United States and abroad.

Since then, PERSES has destroyed more than 6 million gallons of hazardous and nonhazardous waste at a variety of customer sites, including approximately 200 different types of liquids, solids, and slurries. Its ability to handle complex waste streams – such as biosolids, sludges, and chemical mixtures – gives it a clear advantage over emerging technologies still in development.

In 2022, the U.S. Environmental Protection Agency conducted independent testing of PERSES using Aqueous Film Forming Foam (AFFF), a PFAS-laden firefighting material. The EPA confirmed destruction rates exceeding 99.99%, verifying PERSES’ efficacy in treating real-world PFAS contamination.

Built for the field

PERSES is engineered for flexibility and scalability. Each standard unit can destroy 3 to 5 gallons of PFAS-contaminated liquid per minute, regardless of concentration. Multiple systems can operate in parallel to increase throughput. The technology is available in both fixed skid systems for permanent installations and mobile ISO container units (20 feet by 8 feet) for on-site deployment.

Unlike other SCWO systems still in the lab or pilot phase, PERSES is already operating in the field and is considered a Technology Readiness Level (TRL) 8 or 9, meaning it has been fully qualified through testing and is proven in operational conditions. Competing technologies often rely on pipe reactors, which are prone to corrosion and salt buildup. Others require hazardous materials like liquid oxygen or hydrogen peroxide, increasing operational risks and costs. PERSES avoids these pitfalls with a patented vessel reactor design that minimises maintenance and maximises uptime.

GA-EMS also provides full lifecycle support, including procurement, installation, training, spare parts, maintenance, and aftermarket support, to ensure continuous, reliable operation.

Destroying PFAS at the molecular level

The core of PERSES’ effectiveness lies in its use of supercritical water. When temperatures exceed 374°C (705°F) and pressures rise above 3,200 psi, water enters a supercritical state – no longer behaving like a typical liquid or gas. In this unique phase, organic compounds, including PFAS, become fully miscible with oxygen, enabling rapid and complete oxidation.

This reaction breaks the notoriously strong carbon-fluorine bonds that make PFAS so persistent. The result is a clean conversion of hazardous waste into neutral water, carbon dioxide, and mineral salts. Because the process occurs in a single, dense phase, there are minimal mass transport limitations, making the reaction both fast and thorough.

PERSES requires no afterburners, no secondary off-gas treatment, and no exotic chemicals for gas or liquid discharge. It’s a closed-loop system engineered for safety, simplicity, and sustainability.

Tackling complex waste streams

One of PERSES’ key advantages is its ability to handle co-contaminants – other hazardous organic materials that are often present in PFAS waste. Many emerging technologies struggle with these mixed waste streams, requiring preprocessing or multiple treatment stages. PERSES, by contrast, destroys PFAS and co-contaminants simultaneously, maintaining its 99.99% or greater percent efficiency across a wide range of waste feed inputs.

This capability is especially important for real-world applications, where PFAS rarely exists in isolation. Whether it’s contaminated groundwater, biosolids, or industrial sludge, PERSES treats it all in a single, continuous process.

Field demonstrations

Before PFAS became a widespread environmental concern, GA-EMS had already deployed its SCWO systems under US government contracts, followed by commercial sales to various end-users starting in 2012.

Under multiple contracts, GA-EMS continues to demonstrate the PERSES system across a wide range of PFAS-contaminated materials, including concentrated AFFF, diluted groundwater, biosolids, soils, and solid media such as granular activated carbon (GAC) and resin beads from filtration systems.

The projects include the delivery, installation, and operation of PERSES units for multiple waste destruction trials. As PFAS contamination continues to raise concern across industries and communities, interest in testing and deploying effective destruction technologies like PERSES is growing rapidly.

Ready today, designed to last

PERSES is the only field-proven, commercially available SCWO system offering remediation companies a scalable, permanent solution for PFAS destruction. While other systems remain in development, PERSES is already delivering results.

Many competing technologies face significant technical hurdles, including corrosion, salt clogging, and limited temperature thresholds. Some rely on pipe reactors that degrade over time or require frequent maintenance. Others depend on hazardous oxidisers or special reagents that increase cost and complexity.

PERSES avoids these issues by design. Its patented vessel reactor is built to withstand extreme conditions without degradation. It operates without liquid oxygen or hydrogen peroxide and maintains performance across a wide range of waste types and concentrations.

A scalable, sustainable future

As PFAS contamination spreads and environmental regulations grow more stringent, the need for permanent solutions becomes increasingly urgent. PERSES rises to meet this demand with a combination of field-proven destruction, EPA-verified performance, scalable throughput, and clean results that require no post-treatment.

Unlike conventional methods that leave behind residuals or secondary waste, PERSES offers true zero-residue certainty. It’s not just a promising technology; it’s a deployed and operational solution making measurable impacts in communities, military bases, and industrial sites across the country.

GA-EMS continues to invest in the evolution of PERSES, expanding its capabilities and supporting its customers with full-service integration. Whether deployed as a fixed installation or a mobile unit, PERSES is ready to meet the growing demand for PFAS destruction – today and into the future.

Destruction, redefined

PFAS contamination has been building for decades. PERSES offers a permanent, science-backed solution that’s ready now. It’s EPA-tested, commercially deployed, and engineered to deliver what others only promise: fast, safe, and complete PFAS destruction.

As environmental regulations tighten and public demand for accountability grows, PERSES stands out as a technology that doesn’t just manage contamination – it eliminates it. And it does so with the power, precision, and permanence worthy of its titan name.

References

- U.S. Environmental Protection Agency. Industrial SCWO for the Treatment of PFAS/AFFF Within a Water Matrix. EPA/600/R-22/257, September 2022. epa.gov/research

- McDonough, J.T., et al. “Validation of Supercritical Water Oxidation to Destroy Perfluoroalkyl Acids.” Remediation Journal, February 22, 2022. Read the article

- Enviro Wiki. “Supercritical Water Oxidation (SCWO).” enviro.wiki overview

- Sahle-Demessie, E., et al. “Industrial Supercritical Water Oxidation for Aqueous Phase Treatment of Concentrated PFAS/AFFF.” Presented at the American Chemical Society Spring 2023 Conference, March 29, 2023, Indianapolis, IN. Division of Environmental Chemistry, U.S. EPA. Conference schedule

- National Library of Medicine. “Serum Biomarkers of Exposure to Perfluoroalkyl Substances in Relation to Serum Testosterone and Measures of Thyroid Function among Adults and Adolescents from NHANES 2011–2012.” Full article

- Mount Sinai Health System. “PFAS Exposure Linked to Increased Type 2 Diabetes Risk.” EBioMedicine, The Lancet, July 2025. Full study

Please note, this article will also appear in the 23rd edition of our quarterly publication.