Puragen’s global award-winning technology removes and destroys PFAS group chemicals, and is based on activated carbon purification and advanced thermal reactivation.

PFAS group chemicals (per- and poly-fluoroalkyl substances) are a huge group of manmade chemicals that have been widely used in industry since their introduction in the 1950s.

Thanks to their specialised chemical properties, they find multiple uses in many different applications, including:

- Non-stick cookware

- Firefighting foams

- Food packaging

- Fabric coatings

- Cosmetics

They are extremely stable molecules that do not readily break down in the natural environment and, as a result, have been termed ‘forever chemicals’ by certain parts of the media. Some PFAS are defined as persistent organic pollutants (POPs). PFAS bioaccumulates in plants and animals, which is a concern since some PFAS compounds have been linked to serious health risks such as immune system interference, developmental issues, and even certain types of cancer.

A growing concern

Even though these problematic chemicals have been in widespread use for over 70 years, it is only relatively recently that they have started to receive the level of attention they deserve, with many industrial sectors now acutely aware of the issues they face in terms of dealing with these compounds, both in terms of current production and use, plus legacy issues associated with historic on-site usage. In addition to the environmental and health and safety issues surrounding these chemicals, companies also face reputational damage as public awareness increases on this important subject. Governments and environmental regulators in various parts of the world are actively studying the issues surrounding PFAS chemicals and investigating possible ways of limiting their use, as well as options for cleaning up existing contamination.

Regulators are, in parallel, looking into restrictions on the production and use of particularly problematic PFAS compounds, whilst also investigating treatment options for water and air that is contaminated with PFAS, including setting suitable and realistic limits. As an example of the former, three of the most toxic PFAS compounds have been banned in the EU and UK for a number of years – PFOS since 2008, PFOA since 2020, and PFHxS since 2023. However, end-use restrictions, for example the use of PFAS in textiles and firefighting foams, can have long transition periods (sometimes as long as five years) to give industries the time to identify replacement compounds and also phase out existing stocks of affected items. In some applications, the specialist heat- and chemical-resistance of PFAS compounds may mean that no suitable drop-in replacements may be identified, and derogations are therefore likely to follow.

In terms of treatment options, to reduce PFAS levels in water, there are several technologies commercially available to remove these compounds, as well as many other techniques in R&D and pilot stages. Examples of commercial process include the following:

- Granular activated carbon (GAC)

- Membrane filtration

- Ion exchange resins

- Advanced oxidation processes

There are pros and cons of each technology, although the US Environmental Protection Agency (EPA) has identified GAC as a best available technique for the removal of PFAS from water.

One key advantage of the use of GAC over other technologies is what happens to the PFAS once it has been removed from the water. Rather than simply concentrating the PFAS, requiring subsequent incineration of the media to destroy it completely, a properly-designed GAC filtration system, combined with advanced thermal reactivation, can recycle the filtration medium and completely destroy the PFAS contaminants, making it a uniquely circular solution in the fight against these problematic compounds.

Puragen

Puragen is a leading global supplier of activated carbon filtration systems. Previously known as CPL Activated Carbons in the UK and CPL GalaQuim in Spain, the Puragen group merged all of its global subsidiaries in July 2025 to form a single group with a unified strategy and updated branding.

Puragen can supply activated carbons on a global basis. Additionally, in certain key territories, it can also supply a full suite of accompanying services, including the following:

- Wide range of activated carbons, supplied under the FiltraCarb® and FiltraPure® brands.

- A range of mobile carbon filters, manufactured in-house and supplied on a rental basis, for both liquid phase (AquaSorber®) and gas phase (VOCSorber®) purification applications.

- Spent carbon recycling via thermal reactivation, with separate processes for drinking water, wastewater/environmental and high-sulfur biogas applications.

- Site Services teams to assist customers with carbon and filter installation and change-outs.

- Full engineering support to supply peripheral items such as pipework, pumps, valves, etc., if required, at sites that have not previously used activated carbon purification in their process.

- Full QC and R&D back-up, with a range of analytical techniques.

The Puragen team is a very experienced and technically capable group of environmental professionals, who work closely in partnership with customers to help them solve their purification challenges.

The Puragen team have won multiple awards for their innovative technologies, including a global Green Apple award for their PFAS abatement system, which they have entitled ‘Search, Capture & Destroy’. The main elements of this approach can be summarised as follows:

Search: The use of advanced analysis techniques, such as LC-MS, to identify specific PFAS compounds in customer samples, and hence to select the optimum treatment solution.

Capture: The selection of specialised surface-modified GAC to efficiently remove PFAS from water.

Destroy: Advanced thermal reactivation that completely destroys the PFAS in the spent GAC.

Surface modified GAC

PFAS compounds exist in a wide range of sizes and molecular configurations. Whereas standard activated carbons have proved effective at the removal of longer chain-length PFAS from water, shorter chain-length PFAS have traditionally proved more difficult to abate.

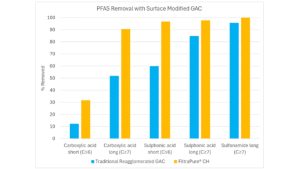

Puragen’s technical team has developed a range of specialised GAC, featuring modified surface chemistry, to dramatically improve the removal performance of shorter chain PFAS, i.e. less than six carbons in the chain. As shown in the graph below, increased removal efficiency of up to 200% is possible, versus traditional reagglomerated carbons typically used for drinking water purification applications. These surface modified carbons, referred to as the FiltraPure® CH range, also offer improved removal efficiency for longer chain PFAS, and generally last longer in customers’ filters before requiring changeout.

Advanced thermal reactivation

Spent carbons can usually be recycled by thermal reactivation in a specialised kiln or furnace. This process removes the impurities from the carbon pores and destroys them via a multi-stage treatment process. Puragen has three separate process streams at its UK reactivation facility, for recycling carbon from potable water, environmental purification and biogas/biomethane operations.

Due to the very stable nature of PFAS group molecules, there has been considerable uncertainty and debate regarding whether thermal reactivation could indeed destroy the PFAS as part of this process. Puragen has developed an advanced reactivation technology, called REACT-Sys+, that completely removes the PFAS from the spent carbon and destroys the PFAS molecules in a three-step treatment process:

- Rotary high temperature reactivation kilns

- Off-gas treatment in thermal oxidisers

- Final off-gas polishing in chemical scrubbers

Independent external testing has confirmed PFAS levels in the air emissions from the process are at the same level as background readings, and that the wastewater stream from the process does not contain detectable PFAS. It has also been shown that no PFAS remains on the reactivated GAC, meaning it can be used again for water treatment without re-introducing any PFAS into the environment.

Puragen can therefore justify its claim that its process not only efficiently removes PFAS from water and air, but can completely destroy the PFAS whilst recycling the spent carbon – culminating in the project title ‘Search, Capture & Destroy’.

Awards

Puragen was awarded a prestigious Green Apple Award for Environmental Best Practice at an event at Kensington Palace in London in November 2024 – pictured below – and were subsequently put forward as UK Ambassadors in the global Green Apple Awards, held in New Zealand in May 2025, where they also won their category against some of the world’s largest companies – a proud moment indeed for the whole of the Puragen team!

So, if you are concerned about legacy or ongoing PFAS contamination problems in your water or air streams, please get in touch with the team of technical experts at Puragen who will discuss the most appropriate treatment solution with you and work in partnership to resolve your environmental issues.

Please note, this article will also appear in the 23rd edition of our quarterly publication.