Films for Future (F3) project seeks to end packaging waste with sustainable cellulose-based coatings.

The F3 project, launched in 2022, is a collaborative effort between VTT Technical Research Centre of Finland, LUT University, and 34 industrial partners innovating sustainable packaging.

Funded by the EU’s ERDF funding programme, this initiative aims to develop a sustainable, cellulose-based film alternative to replace plastic films currently used in packaging (Figs. 2 & 4).

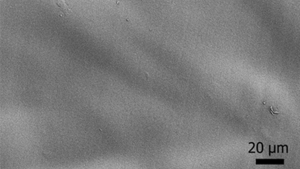

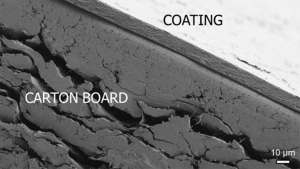

The F3 project has advanced from transparent standalone cellulose films to producing coatings on different board grades with enhanced material barrier properties. Compared to films, less material is required for the coating of the board to enhance the material’s gas barrier performance, with the board functioning as support material. The smooth coating surface can be easily utilised for further layering when required (Fig. 3).

on a carton board

The films, as well as the coatings, are produced in a continuous manner at VTT’s regenerated Cellulose Films pilot line located at Bioruukki Espoo, Finland (Fig. 1).

Coating and films have been processed in addition to conventional fibre source (dissolving pulp grade), also using kraft pulps (from softwood and hardwood) with alkaline dissolution. Use of kraft pulps as a raw material enables F3 technology integration into existing sites, including pulp mills.

One of the main goals for the F3 project was to assess the created materials’ recyclability profile. The coated board recycling was tested in soil, marine environment, and utilising industrial composting standards. Results showed that a board with F3 regenerated cellulose coating does not add to the biodegradability of the cardboard and can be recycled according to PPWR regulations.

F3 project achievements were recognised recently by The New Wood project, launched in 2014 in Finland, involving 20 Finnish organisations across the forest industry, awarding F3 fossil-free cellulose coating with third place in their Uusipuu contest held in October 2025.

Plastic waste poses a major environmental challenge, and the F3 project has tackled this issue by delivering a sustainable, eco-friendly alternative that meets the requirements of the EU Packaging and Packaging Waste Directive (PPWR). This innovative bio-based and biodegradable material has the potential to transform the packaging industry by reducing dependence on conventional fossil-based plastics.

Partner companies in the Films for Future project:

Ahlstrom, Berndorf Band GmbH, CMPC Ventures SpA, Colombier Finland Oy, Domtar, DS Smith Paper Limited (GBCE), Fiber-x Finland Oy, Fortum Power and Heat Oy, General Mills Inc., Graphic Packaging International LLC, Henkel AG & Co. KGaA, Joutsen Paino Oy, Kemira Oyj, KLABIN SA, Leipa Group GmbH, LIST Technology AG, Mega Cellulose Oy, Metsä Board Oyj, MM Kotkamills Boards Oy, Neenah Gessner GmbH, Nordic Bioproducts group Oy, Paroprint Oy, Philip Morris Products SA, Pixact Oy, Solenis LLC, Sulzer Pumps Finland Oy, Suominen Oyj, Suzano SA, Sylvamo Corporation, Yangi AB, Unilever R&D, UPM-Kymmene Oyj & Valmet Technologies Oy.

Disclaimer

F3 – Films for Future programme is funded by the European Regional Development Fund (ERDF) and participating companies. Grant agreement No. A80423.

Please note, this article will also appear in the 24th edition of our quarterly publication.