RockFuel is redefining cement, turning concrete infrastructure and construction into a solution for global decarbonisation that is True Net Zero.

As the world intensifies its efforts to combat climate change, industries under mounting scrutiny are being challenged to innovate or become obsolete. Cement production, responsible for approximately 8% of global CO₂ emissions, is a prime target for transformation. Now, a pioneering solution from UK-based company RockFuel promises to revolutionise the sector: a Carbon Negative cement process that doesn’t just lower emissions – it reverses them.

With a patented closed-loop manufacturing system that produces ‘carbon neutral CO₂’, RockFuel’s approach offers a scalable, economically viable, and truly climate-positive alternative to conventional cement. This development marks a significant milestone in sustainable construction and positions RockFuel as a key player in the decarbonisation of the global construction materials industry.

Cementing a new future with carbon capture

At the heart of this innovation is RockFuel’s Carbon Neutral Lime Kiln, a high-efficiency system that produces quicklime (CaO) while capturing the CO₂ released during the process. Traditional cement kilns vent this CO₂ directly into the atmosphere. RockFuel’s closed-loop kiln, powered entirely by renewable energy sources – including solar, wind, hydroelectric, or energy recovered from other RockFuel processes – collects over 500 cubic metres of hot CO₂ per cubic metre of limestone rock processed, storing it in a dedicated tank for reuse.

The captured CO₂ is not simply stored or sequestered, it is reintegrated into the production cycle in a novel way, forming the basis of RockFuel’s Carbon Negative cement solution. By closing the loop and incorporating carbon capture at the manufacturing stage, RockFuel offers a blueprint for next-generation industrial processes.

From emission source to carbon sink

In RockFuel’s Carbon Neutral cement process, the cement begins as quicklime (CaO – Calcium Oxide), produced in the company’s kiln from CaCO3, powered by Carbon Neutral energy. It is then blended with clay to create cement, while the captured CO₂ undergoes electrolysis, using excess energy from the system, which contributes towards a carbon-neutral process. This yields solid carbon and carbon-neutral oxygen, both valuable industrial byproducts.

Solid carbon can be used in advanced materials such as carbon fibre and graphene, while oxygen finds applications in steel manufacturing, wastewater treatment, medical technology, and the chemical industry. This multi-output system ensures minimal waste and creates new revenue opportunities, enhancing commercial appeal for investors and manufacturing partners.

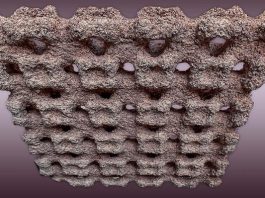

Crucially, when RockFuel’s cement is used in construction and the resultant concrete begins to cure, it absorbs additional atmospheric CO₂, turning infrastructure into long-term carbon sinks. This makes the product not just Carbon Neutral, but Carbon Negative across its lifecycle — a critical differentiator in the race toward global decarbonisation in the built environment and infrastructure projects worldwide. While some governments do not generally accept the figures for this natural carbon curing effect, the RockFuel Carbon Negative Cement Process includes a very small fraction of calcium oxide used in ocean projects, where around double the amount of CO₂ is absorbed, which ensures the whole process is Carbon Negative.

Meeting global market demands

The cement industry is forecast to grow from $316.3bn in 2020 to over $463bn by 2026, driven by infrastructure investment, population growth, and urbanisation across all continents. As nations introduce stricter carbon policies, the demand for climate-positive materials is rapidly increasing.

While the Asia-Pacific region continues to dominate production volumes, North America and Europe are leading in regulatory pressure and innovation-driven sustainability strategies. Both public and private sectors, governments, investors, and project developers are searching for materials that offer verifiable carbon reductions without compromising performance, compatibility, or cost-effectiveness. RockFuel’s solution addresses all three.

The chemical properties of the cement remain identical to traditional formulations, meaning it can be used in existing applications, such as poured concrete or precast components, without altering construction methods or regulatory standards. This makes it an ideal drop-in alternative for infrastructure projects, from transport networks to commercial buildings and renewable energy installations, such as the cement foundations for wind turbines and electricity transmission towers.

Verified, patented, and ready for global partnerships

RockFuel’s technology has undergone independent chemical engineering validation and financial modelling, demonstrating both technical feasibility and commercial viability. The company holds multiple international patents, with further applications pending, ensuring that this innovation is protected and ready for global licensing and industrial adoption.

The company is now seeking strategic partnerships with:

- Cement, lime, concrete producers, and lime kiln manufacturers looking to decarbonise operations and ensure their long-term viability in a climate-positive world;

- Universities and research institutes interested in co-operating on materials science, industrial chemistry, or sustainability innovations, e.g. via Horizon Europe collaboration;

- Government agencies focused on green infrastructure, industrial transition, a climate-positive built environment and clean energy policy;

- Impact investors and clean-tech funds seeking scalable, commercially sound climate solutions that are profitable and ready for upscaling.

Building toward a truly sustainable planet

The cement industry has long been seen as incompatible with true sustainability goals. RockFuel is overturning that perception. With a technology that turns CO₂ emissions into valuable outputs and cement-based infrastructure into carbon sinks, RockFuel is not just reducing the impact of cement, it is transforming it into one of the most climate-positive building materials available.

This innovation has the potential to reframe how construction contributes to environmental targets, no longer as a reluctant emitter, but as an active agent in atmospheric carbon reduction. It allows built environments to become tools in the fight against climate change, offering governments and industries a real, scalable way to build better and cleaner.

As the world races to decarbonise, RockFuel offers a ready-to-implement ‘Real Zero’ solution for one of the hardest-to-abate sectors. For policymakers, researchers, and industry leaders, it represents a beacon of what’s possible when circular design, energy transition, and practical innovation converge.

Please note, this article will also appear in the 22nd edition of our quarterly publication.