Solinatra’s bio-based resins offer a truly sustainable alternative to plastic in various sectors, while remaining compatible with standard production systems.

Solinatra delivers 100% natural, plastic-free, compostable and biodegradable materials that make it easy for industries to transition to sustainability without compromising performance, process, or planet.

Founded to address the urgent need for sustainability solutions, the company designs and produces fully compostable and biodegradable materials made from agricultural byproducts. These materials provide the same consumer experience as traditional plastics while delivering environmental benefits aligned with global regulations and compostability standards.

With a focus on compatibility, circularity, and user experience, Solinatra’s materials offer a reliable and commercially viable pathway for industries aiming to reduce waste, meet regulatory targets, and shift away from fossil-based systems. Each resin is designed not just for environmental impact, but also for ease of adoption by manufacturers using existing infrastructure.

Solinatra’s biobased and biodegradable materials are certified to internationally recognised standards, including EN 13432, ASTM D6866, and comply with Regulation (EU) No. 2020/1245 (amending Regulation (EU) No. 10/2011). Food-contact safety and compostability claims are validated through third-party testing performed in accordance with EN 1186, giving brands and manufacturers confidence in performance and compliance.

Solinatra materials

The core product range includes three primary bio-resin grades. The first, designed for injection moulding machines, Solinatra Bio-resin, like Universal Food, is developed for neutral-coloured, food-contact applications and is widely used for catering items, such as compostable utensils and trays. Universal Light and Universal Dark resins provide alternative tones and aesthetic versatility, both supporting colour adjustment using natural masterbatches. All grades meet rigorous compostability and safety benchmarks.

For flexible product designs, Solinatra offers variants such as Food Flex, Light Flex, and Dark Flex. These allow for moderate bending and compression without cracking or stress whitening, making them ideal for moulded parts with dynamic use.

The extrusion-compatible range features Light X, Dark X, and Straw resins. These support flat or tubular profiles, such as compostable straws or agricultural tubing, while ensuring structural performance during use and dependable disintegration afterwards.

Solinatra is home and industrial compostable, certified by TÜV Industrial. It breaks down under both natural and controlled conditions without generating microplastics or leaving chemical residue. All properties are verified through internationally recognised testing protocols.

By offering this portfolio of bio-based resins, Solinatra supports manufacturers seeking sustainable plastic alternatives for various production lines, while delivering the strength and quality required in real industrial environments.

Integration

Materials made from renewable sources often fail under mechanical and thermal stress during production. They can clog injection moulds, degrade with heat, or require expensive process adjustments. Solinatra resins are specifically formulated to solve these issues.

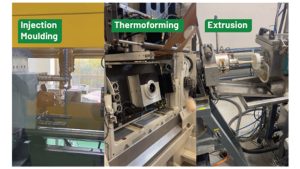

Solinatra operates directly on standard plastic processing equipment, including injection moulding, extrusion, and thermoforming machines. The resins follow a well-known thermal profile and do not need tooling modifications, die changes, or reconfiguration of runner systems. For manufacturers, this means avoiding capital expenditure on new infrastructure and preventing disruptions to existing line operations.

During production, Solinatra resins maintain consistent flow behaviour and output quality. Parts are formed cleanly, even during repeated high-volume cycles. Reports from commercial partners confirm there is no reduction in yield or increase in cycle time after switching from petroleum-based polymers.

For companies using flex-grade resins, Solinatra supports product types that require slight flexibility or contact resilience. These are compatible with existing moulds and automation sequences, even in sectors such as medical devices or food-service packaging.

The core principle is reliability. Solinatra resins were not designed for niche performance – they were developed for scalable production in actual factories. Switching to Solinatra does not require compromise, disruption, or retraining.

Applications

Solinatra’s bio-based, plastic-free resins are already utilised across multiple industries. These are not pilot trials – they are proven applications in functioning supply chains.

In the food and beverage sector, Solinatra resins are used to manufacture biodegradable cutlery, compostable straws, and sustainable coffee capsules. All are safe for food contact, heat resistant within operational limits, and structurally stable under handling conditions. These products degrade in weeks under home or commercial composting environments, leaving behind no microplastics or chemical residues.

In agriculture, Solinatra resins are used in mangrove planting pots that support ocean-side reforestation without polluting fragile marine ecosystems. On land, the same materials form thermoformed nursery pots that break down safely in soil or compost after use. These solutions are designed for direct deployment in the field with minimal environmental impact.

In the tourism and hospitality industry, Solinatra is used to produce single-use hotel amenities, including toothbrushes, combs, shoe horns, and cotton bud sticks. These daily essentials provide the convenience and familiarity of traditional plastic but are made from materials that decompose cleanly and safely.

These examples demonstrate a simple but powerful truth: if a product can be made from plastic, it can also be made from Solinatra. The material is available in various grades to suit stiffness, flexibility, and mouldability requirements. All formats are compatible with standard machinery, ensuring quick and cost-effective adoption.

For projects requiring customised performance, Solinatra resins are available for adjustment. The company collaborates with converters and brands to fine-tune material properties such as heat resistance, tensile strength, or composting speed – ensuring the material suits both the product and its sustainability targets.

Solinatra demonstrates that sustainable bioplastic materials are not limited to packaging or low-load items. These resins are practical, scalable, and already assist brands in replacing traditional polymers without compromising the comfort their customers experience or ease of manufacturing.

For more information, visit www.solinatra.com or explore how Solinatra fits into your existing production lines at www.solinatra.com/seamlessly-integrated.

Please note, this article will also appear in the 23rd edition of our quarterly publication.