Lisa-Lou Gracia, Project Manager at CEA, considers how ‘VERSAPRINT’ is using smart printing technologies to build the next generation of battery systems for all modes of transport.

In the fast-evolving world of electromobility, batteries are often designed with narrow use cases, limiting their adaptability across sectors and slowing innovation. VERSAPRINT, a European collaborative research project, challenges the status quo with a bold proposition: what if battery systems could be modular, multifunctional, and sustainable from the start? With this vision, VERSAPRINT is building a new generation of battery systems, tailored not just for performance, but for cross-sector integration and scalable manufacturability. From aviation to automotive, rail to waterborne transport, VERSAPRINT’s flexible architecture and eco-design principles aim to make batteries smarter, safer, and future-ready.

While much of the conversation around batteries focuses on energy density and cost, VERSAPRINT adds a new layer of innovation: integrating smart, lightweight, and recyclable components, using additive manufacturing techniques like 3D printing. Its mission is clear: design safer, more sustainable, and adaptable battery systems, empowering Europe’s industry to lead in the global battery race.

Modular technology for a multifaceted market

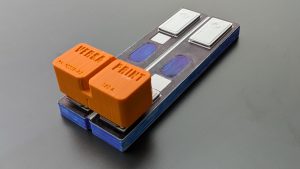

Battery packs today are often one-size-fits-all, designed for mass manufacturing. But mobility needs are anything but uniform. A battery module for an urban EV shares little with a battery system for a maritime vessel or a light aircraft. VERSAPRINT tackles this challenge with a modular architecture built from smart building blocks (BBs), each addressing key functions like thermal management, interconnection, sensing, and structural protection.

These BBs are designed to be mix-and-match components. They can be tailored to specific formats, chemistries, voltages, and applications. This flexibility provides real value for industry: faster development times, easier customisation, and better alignment with use-case requirements.

VERSAPRINT’s modularity also means better scalability across industries. With aeronautic and automotive applications already prototyped, simulations are extending the benefits to rail, waterborne, and off-road applications. This wide-ranging applicability increases the relevance and market reach of the project’s outcomes.

Why additive manufacturing?

Additive manufacturing – 3D printing – is central to VERSAPRINT’s strategy. But it’s not used for novelty. It enables functionality that traditional methods struggle to achieve.

“We use advanced 3D printing to embed functions and value directly into the battery system,” explains Lisa-Lou Gracia. “With 3D printing, we can insert flame retardants, integrate complex internal structures for heat management, or reduce part count through multifunctionalisation.”

For example, the 3D-printed silicon-based microchannels for the cooling system (BB1) drastically reduce weight – by over 25% compared to traditional metal counterparts. This solution doesn’t just cool the cells; it increases energy and power density by maintaining optimal temperatures during charging and discharging.

Still, the project remains grounded. The 3D-printed casings, for instance, are not intended as a final manufacturing solution, but as a testbed for integrating functionality and improving recyclability.

Smarter battery sizing through simulation

One of VERSAPRINT’s standout contributions is its Decision Tool, a simulation engine built in MATLAB Simulink. This tool allows engineers to design optimal battery modules based on specific constraints like pack voltage, capacity, and cell format. It even factors in cell ageing, enabling more accurate lifetime estimates.

Here’s what it does:

- Suggests optimal cell chemistries based on the targeted application, available space, and thermal profiles.

- Recommends the best combination of VERSAPRINT BBs for a specific application to balance performance, weight, cost, sustainability, and safety.

- Provides fast iteration and sensitivity analysis to optimise both technical performance and environmental footprint.

This decision-making backbone not only accelerates design time but also reduces risk. By simulating outcomes before manufacturing, companies can avoid costly missteps and develop tailor-fit solutions with confidence.

Sustainability as a design principle

Unlike other battery projects that add sustainability assessments at the end, VERSAPRINT integrates eco-design from the start. The result is not just greener batteries but smarter product development.

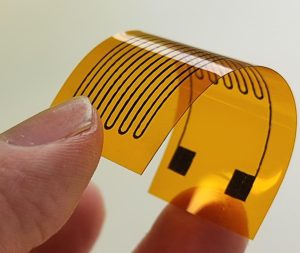

Take the bio-based, water-soluble inks used in printed sensors (BB2). These sensors reduce environmental harm by avoiding toxic solvents and materials. Printed on foils rather than directly on cells, they also simplify integration and reduce production waste.

Add to that VERSAPRINT’s busbars (BB3 and BB4), designed for fast manual disassembly and second-life reuse. One design reduces module disassembly time from over two hours to just 13 minutes – a potential game-changer in recycling economics. Disassembly cost drops from €3.99/kWh to just €0.36/kWh.

Beyond materials, the project evaluates environmental footprint throughout each building block’s life cycle, with a final system-level analysis coming in the next phase.

Boosting safety and lifetime

Safety is a cornerstone of VERSAPRINT’s value proposition. All BBs play a role in preventing or mitigating thermal runaway (TR), a key failure mode in lithium-ion batteries.

- Cooling system (BB1): Prevents overheating during fast charge/discharge cycles and maintains optimal cell temperature to extend cell life.

- 3D-printed temperature and hydrogen sensors (BB2): Monitor early warning signs of TR and enable faster response.

- Busbars (BB3/BB4): Integrate electrical, thermal, and safety functions while being easy to dismantle for maintenance or end-of-life processing.

- Gas and particle filter (BB7): Cools exhausted gases and traps solid ejections during TR, reducing the risk of fire propagation to adjacent cells.

Recent lab findings show that, with VERSAPRINT’s cooling system (BB1), a 3C charge/discharge can be sustained while keeping cell temperatures below 55°C, a significant safety margin. Moreover, tests on the exhaust gas management system (BB7) show that the temperature of ejected gases during thermal runaway can be cut in half, effectively preventing fire and thermal propagation beyond the battery module.

Industrial guidance from the start

VERSAPRINT technologies are being shaped not just in labs, but through continuous feedback from industrial leaders across aeronautics, automotive, and energy sectors. Companies like Airbus, BMW, and Turkish Aerospace are actively reviewing and validating the project’s outputs.

Their questions aren’t academic. Why 3D-printed sensors when commercial ones exist? Are the casings compliant with electromagnetic compatibility (EMC) regulations? How robust are the connectors in harsh environments?

These inquiries shape real project decisions. The sensors, for instance, are now printed with bio-based ink on foils, reducing environmental impact and improving integration. Connectors are being tested with both overmolded and 3D-printed housings, and modules will undergo rigorous shock and vibration tests to prove their robustness and resilience.

Looking ahead

As VERSAPRINT moves into its next phase, prototype validation and end-user demonstrations will be key. Initial results estimate a 15% improvement in mass density, with gravimetric energy densities reaching up to 155 Wh/kg using NMC cells. Thermal performance is also extending high-power output from 15 to 30 minutes, doubling the available power without compromising safety.

The promise is clear: smarter, safer, greener batteries that scale across diverse mobility sectors. And because they are designed with sustainability, disassembly, and modularity in mind, they offer a roadmap to circular battery systems that Europe can both manufacture and recycle.

As the global race toward electrification accelerates, VERSAPRINT is setting a new standard in battery system design, where research and innovation respond directly to the needs of industry. Through advanced materials, 3D-printed multifunctional components, sustainable sensing technologies, and simulation-based design tools, the project demonstrates how integrated thinking can bridge the gap between efficiency and circularity.

With constant feedback from leading industrial players in automotive, aeronautics, and energy sectors, VERSAPRINT is paving the way toward truly adaptable, safe, and sustainable battery systems, ready to power the electrified future across land, sea, and air.

Who’s behind VERSAPRINT?

Co-ordinated by the Commissariat à l’Énergie Atomique et aux Energies Alternatives, VERSAPRINT brings together a multinational consortium of ten partners from five European countries, spanning the entire battery value chain. This includes LEITAT, Fev Europe, Centro Ricerche Fiat, SONACA, Efesto, Avesta, LOMARTOV, RWTH Aachen University, and OPmobility, each contributing their unique expertise to drive the project forward. From materials development and additive manufacturing to eco-design and life cycle assessment, each partner plays a crucial role in turning modular battery concepts into real-world solutions ready for industrial adoption.

Please note, this article will also appear in the 24th edition of our quarterly publication.