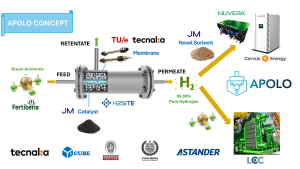

APOLO project, co-ordinated by Tecnalia with technical lead H2SITE, targets the full decarbonisation of the maritime sector utilising membrane technology for ammonia cracking.

The APOLO project (Advanced Power Conversion Technologies based on Onboard Ammonia Cracking through Novel Membrane Reactors) focuses on power conversion for onboard applications by enabling the use of ammonia as a clean alternative fuel for maritime applications. APOLO’s mission is to develop advanced, flexible ammonia-cracking technologies that can be integrated with fuel cells (FCs) and internal combustion engines.

Development of two demonstration prototypes

The consortium will focus on showcasing the following demonstration units (prototypes):

- A 125kW power conversion system that utilises an ammonia cracker (H2SITE) coupled with a proton exchange membrane (PEM) fuel cell (Corvus Energy Fuel Cells and Nuvera, tested separately for different inlet pressures) system, achieving an overall system efficiency of 51% to 54%. The ammonia cracker will be customised to work with different pressure conditions and efficiency levels to evaluate the flexibility of the cracking system for all types of PEM fuel cells.

- A 125kW partial ammonia cracker (H2SITE) coupled with a four-stroke engine (LEC), exhibiting an overall system efficiency above 45%. A selective catalytic reduction (SCR) system will also be developed for the removal of nitrogen oxide (NOX) emissions from the exhaust of the novel engine.

Overall, APOLO has the ambition to design and test a new modular, easily scalable and flexible fuel supply system, including a new compact membrane reactor, which may be used interchangeably with an internal combustion engine or fuel cells. This membrane reactor will allow the offer of an adequate fuel mixture for its utilisation in a thermal engine or a pure hydrogen stream with fuel cell grade to feed a PEM fuel cell. This innovative fuel supply system will be integrated into a complete power conversion system, and optimisation work will be performed using both modelling and experimental work to find the most relevant ship configuration. For the first time, APOLO will build, validate and compare two different power conversion technologies with an overall process efficiency ranging between 45% and 51%.

The technologies developed in APOLO will be capable of targeting the first 30,000 ships in the market. Initially, the focus will be on vessels with 1 to 10 MW propulsion, with a significant number of them being around 3 MW in the next decade, as these are the first vessels relevant for ammonia-powered solutions.

Ammonia cracking through membrane reactors (CMR)

The core of APOLO technologies is ammonia decomposition, also known as cracking. Through this process, ammonia (NH3) is converted to nitrogen (N2) and hydrogen (H2) is converted to nitrogen (N) and hydrogen (H) (2NH3 ↔ 3H2 + N2, ΔH = 46 kJ mol-1). It is the reverse reaction of the Haber–Bosch process for the synthesis of ammonia. Ammonia cracking, thus, is a means of hydrogen production, where this hydrogen can be used as a substitute for traditional fossil fuels. The reaction is favoured at low pressures and high temperatures (due to its endothermicity).

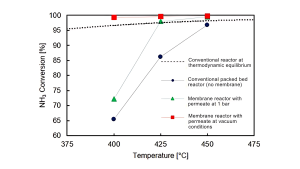

The most common industrial-scale ammonia cracking systems offer an electric-based furnace solution with a packed-bed reactor, which produces a forming gas (H2 and N2 mixture) and operates at very high temperatures, typically 800-900°C. Significant efforts are made to improve this technology by integrating solutions like the use of alternative catalysts to reduce the operating temperature, an additional clean-up system to remove unreacted ammonia (<30 ppm) and N2 (up to 25%) and an ammonia recovery unit for systems requiring high-grade pure hydrogen (ISO 14687:2019), e.g. PEM fuel cells.

Packed-bed catalytic membrane reactors (CMR) offer a simpler solution to this problem. Integrating hydrogen separation membranes into the traditional reactors can help circumvent the thermodynamic equilibrium limitation in order to obtain full ammonia conversion, at lower operating temperatures (400-450°C).¹ In this case, as soon as ammonia is decomposed with the help of the catalysts into H2 and N2, the membranes selectively separate the H2. In APOLO, palladium (Pd) membranes are used for this purpose, which have an H2/N2 ideal perm-selectivity >100,000 at 425°C. This ensures high H2 separation efficiencies at lower operating temperatures compared to conventional systems, which will be beneficial from an energetic point of view. The hydrogen released can be directly fed to the fuel cells, after a much simpler polishing process with a sorbent to remove any excess ammonia to avoid harming the FCs. Since the whole process occurs in a single unit, there is also a huge reduction in physical footprint, which will be beneficial for maritime vessels.

H2SITE, along with Tecnalia and Technische University of Eindhoven (TU/e), have already proven the advantage of a CMR compared to state-of-the-art cracking technologies through EU-funded project ARENHA. Through the APOLO project, further optimisation of these Pd membranes will be carried out by these partners. Johnson Matthey will be investigating innovative, environmentally friendly catalysts for ammonia cracking as well as novel sorbents for hydrogen polishing for fuel cells.

Fuel cell

PEM FCs have gained interest as a potential power source for ships, both for propulsion and auxiliary power. One of their key advantages is their high efficiency, which can exceed that of traditional combustion engines. They also operate with lower noise levels, making them a more comfortable option for passengers and crew members. Moreover, since they do not require combustion, they do not produce greenhouse gases (GHGs) or other harmful emissions. Challenges remain to achieve a hydrogen purity agreeable with the operation of a PEM fuel, as ammonia cracking leads to the production of a forming gas with still high nitrogen and ammonia content for FCs. This will lead to a loss in performance of the fuel cell and probably to its premature degradation. For that purpose, the ISO 14687:2019 pure hydrogen produced by an ammonia cracker, followed by a sorbent polishing step, could be used as the feed to the PEM in order to decarbonise shipping. Corvus Energy Fuel Cells and Nuvera (Hyster Yale SpA) will be performing the testing of fuel cells for both low-pressure and high-inlet-pressure conditions from the cracker.

Ammonia engines

The power conversion system in an ammonia ship operating with an internal combustion engine consists of two main parts: one for propulsion and one for auxiliaries. The engine itself is a critical component of the power conversion system and must be designed to operate with ammonia fuel. Ammonia, being devoid of carbon, does not release any CO2 when it undergoes combustion. Nevertheless, NH3 is a difficult fuel to ignite when used for combustion in engines. Its high ignition energy requirements mean that it either needs a pilot fuel or a ‘hot’ source to ignite properly. A fuel supply system including a cracker for NH3/H2 mixture generation is promising, especially during cold start. Additionally, to optimise heat integration between the cracking and the combustion steps, hot flue gas from the engine’s exhaust can be used to provide heat to the decomposition reactor. An SCR will also be developed based on copper (Cu), iron (Fe), and vanadium (V) for the removal of NOx emissions from the exhaust of the novel engine. Large Engine Competence Centre (LEC) will be leading the research on these ammonia combustion engines, with Johnson Matthey working on the SCR catalysts.

A holistic consortium

Additionally, APOLO derives the expertise of Fertiberia (green ammonia providers), Astander (shipbuilders), as well as 1CUBE (dissemination entity) for a complete implementation, communication and exploitation of its technologies. During APOLO, a Techno-Economic Analysis and Life Cycle Assessment will be performed by Chalmers University, along with a Health, Safety, and Environment assessment inspired by HAZOP/HAZID protocols, which will be done by Tecnalia and Fertiberia. APOLO also aims to suggest amendments to EU and IMO regulations on the use of ammonia as fuel/power conversion systems for the maritime sector through Bureau Veritas.

Currently in M21, APOLO is on schedule with key component development for membrane reactor (membranes, catalysts and sorbents), fuel cells and ammonia engine. During this period, a market analysis with a preliminary exploitation strategy is also performed. Thus, APOLO is fully poised to assist the maritime sector to reach the decarbonisation targets set by FuelEU Maritime, Fitfor55 and European Green Deal regulations.

Acknowledgements

Funded by the European Union under Grant Agreement No. 101138466. Views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union or the European Climate, Infrastructure and Environment Executive Agency (CINEA). Neither the European Union nor CINEA can be held responsible for them.

References

- Gallucci et al., Fuel Processing Technology, 2021, 216, 106772

Please note, this article will also appear in the 24th edition of our quarterly publication.