A researcher from the University of Birmingham has developed a new high-throughput device that produces libraries of advanced materials using sustainable mechanochemical approaches.

The device, created by Dr Jason Stafford from the University’s School of Engineering, is a fully automated unit that can be programmed for parallel synthesis to produce a series of advanced materials made in different ways for further testing and optimisation.

It reduces the amount of time researchers spend generating advanced materials in the laboratory and creates highly controlled reaction times.

Current techniques to synthesise advanced materials

Current techniques for synthesising advanced materials, while effective, are not without their limitations. They rely on a top-down approach that peels off layers of atoms or a bottom-up approach that builds up a sheet by depositing one atom at a time.

These approaches involve a large number of steps and synthesis parameters and rely on thousands of precursors, presenting significant challenges that the new high-throughput device aims to address.

Current approaches hinder research and development of new formulations using nanomaterials made from single elements like graphene or compounds such as copper oxide or crystals.

High-throughput device

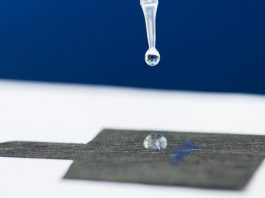

The new device uses mechanochemical synthesis, which accesses new materials and induces chemical reactions through mechanical forces. This reduces the need for toxic solvents.

The high-throughput device works with standard laboratory glassware or custom vessels and can be programmed to deliver different mechanical forces in each vessel.

This may contain anything from a dilute liquid suspension to a dry solid powder.

New materials for chemical manufacturing and drug discovery

The new device is expected to interest professionals working in chemical manufacturing, advanced materials design, and drug discovery.

It will enable the development of new materials that can translate directly into environmentally sustainable manufacturing processes.

Dr Stafford said: “There is a massive and ever-growing library of specialised 2D materials that have not reached mainstream applications, yet researchers are spending up to half of their time ensuring synthesis steps are performed repeatedly and correctly.

“The automated platform can significantly reduce the time and expertise required in these processes and free up scientists to focus on the core aspects of their research in materials discovery.”