The SAFELOOP project is committed to developing a safe, sustainable, and high-performance lithium-ion (Li-Ion) battery for the European EV industry.

SAFELOOP (Securely Advancing Future EVs with Li-Ion batteries through Optimized Pathways) is a 36-month project launched in June 2024, bringing together 15 partners from 11 countries. SAFELOOP is funded by Horizon Europe – the European Union’s flagship research and innovation funding programme. SAFELOOP secured €5m of funding from the European Commission.

Growing urgency for more efficient and reliable energy storage

In a mobile and fast-paced society, the demand for energy storage solutions has never been more critical. As we strive to build a sustainable future relying on renewable energy sources, the need for efficient and reliable energy storage becomes paramount.

The SAFELOOP project is reshaping how batteries for electric vehicles (EVs) are made. The project is developing innovative key battery components – anodes, cathodes, separators, and electrolytes – using recycled materials provided by its consortium members. These will be combined into battery packs designed for e-buses. SAFELOOP aims to make big strides towards the EU’s ambition of making Europe the first climate-neutral continent by 2050.

The need is urgent: by 2025, global EV battery demand is expected to reach 735 GWh, with more than 125 million EVs on the road by 2033. SAFELOOP’s mission is to make these batteries not only more sustainable, but also safer. The project’s primary goal is to elevate the safety, sustainability, and performance of European gigafactory-scale lithium-ion battery cells.

The project aims to increase EV battery lifetime by 15% by 2030, set new safety benchmarks aligned with EUCAR Hazard Level 3 standards for mobility applications, and contribute to Europe’s ambitious recycling targets. To achieve this, SAFELOOP is focusing on building a European supply chain, securing raw materials, reducing reliance on imports, and limiting environmental impacts. The goal is to develop the world’s first EV battery with the required recycled content and improved recycling rate within a decade. By combining research excellence with industrial know-how, SAFELOOP is paving the way for safer, greener, and more competitive European batteries. The project encompasses all aspects of the battery life, and each individual partner offers unique expertise towards achieving the project’s goal.

The SAFELOOP process

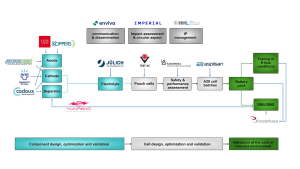

The overall process flow of SAFELOOP and its ecosystem is presented in Fig. 2.

Cathode active materials (NMC and LFP) from primary and recycled raw materials will be prepared. As a more innovative approach, the lithium manganese metal oxide (LNMO) cathode is also synthesised. Electrochemical performance of materials is evaluated using coin cells and pouch cells. The aim is to use raw materials from spent batteries and the metal refining industry from the EU region, and thus decrease the supply chain risk. The project also aims to produce engineered carbon materials and additives to be used in cathodes for the improvement of cyclability and safety.

The goal is to develop an advanced anode material from primary and recycled sources by integrating natural graphite, recycled graphite, synthetic graphite, and nano-dispersed silicon powder. This innovative composite will enhance energy density of the anode, improve cycling stability achieving 2,000 cycles at 80% initial capacity, and support sustainability efforts in lithium-ion battery production, providing a competitive solution for high-performance energy storage systems.

Enhanced safety battery separators, coated on the exterior with a layer of nanoscale Cadoux premium HPA alumina, are qualified. SAFELOOP will furnish 25-micron thick separators, manufactured from ultrahigh molecular weight polyethene and polypropylene. Silica-filled separators will also be evaluated. Later, 15- and 20-micron thick separators, both coated and uncoated, are qualified.

The project will design and develop optimised non-flammable, non-aqueous liquid electrolyte formulations compatible with the project’s defined primary and recycled anode, cathode, and separator to provide 15% improved long-term galvanostatic cycling stability (2,000 cycles, 80% initial reversible capacity, C/3 rate at room temperature) compared to the 2019 baseline cell chemistry, through the formation of effective solid electrolyte interphase (SEI) on anode and cathode electrolyte interphase (CEI) on cathode combined with improved safety (flame retardancy) achieved through implementation of targeted functional additives/co-solvents.

2 Ah capacity pouch cell development studies will be performed. Anode and cathode active materials delivered in previous steps are going to be utilised. Technical parameters will be optimised during electrode development studies.

Safety is crucial

The safety assessment concerns involved with the flammable state-of-art (SoA) battery electrolytes will be addressed through an in-depth study of identified flame-retardant electrolyte additives and co-solvents. The electrolyte formulations developed in the project will be characterised in terms of safety properties, both on the electrolyte and lab cell (coin cell and 2Ah pouch levels). The characterisation of the safety properties will include flash point measurements using a commercial flash point analyser and self-extinguishing time (SET) measurements.

SAFELOOP will perform a comprehensive assessment of the impacts of changes in the recommended materials of a Gen 3 EV-grade battery, based on the tangible benefit it will bring to the performance of the cells. This includes seeing how changes proposed are going to manifest themselves during the entire life cycle of EV batteries, which include the use of these cells in a battery pack, its testing performance, its performance maintenance, transportation, cell disassembly and recycling, and other important life-cycle-related considerations. Importantly, the focus will remain on showcasing safety enhancements primarily around comparing the three iterations cells produced by SAFELOOP with the existing SoA Gen. Three cells, which will be tested at the project’s outset, are specifically generated for mobility applications. Batteries developed in the project will be tested in e-bus conditions, including a road test, charge-discharge test, and performance test.

SAFELOOP will implement safety enhancements at the battery management unit (BMU) level, such as the cell-sensing part of the battery management system (BMS), and then to recommend how those changes can be integrated into the EV design at the BMS level.

Development of innovative and cost-effective recycled LIBs for gigafactory production is one focus area of SAFELOOP, including battery pack unit economics calculations and a patent landscape analysis of LIB recycling technologies in the EU. Value chain mapping, eco-design guidelines, and environmental and social assessment are also considered in SAFELOOP to support commercialisation potential.

Partnerships

SAFELOOP is also a proud contributor to the BATT4EU partnership and is a member of the Battery 2030+ cluster. Among others, through its activities, BATT4EU aims for widespread adoption of e-mobility and stationary electrical energy storage. SAFELOOP will particularly support Batt4EU’s specific objective on supporting the development of different technologies in battery materials, cell design and manufacturing, and battery recycling. Battery 2030+ and Batt4EU networks to strengthen impact and create synergies with other Battery Innovation initiatives throughout Europe. Strong synergies have been established also with our sister projects, INERRANT and SAGELi.

Please note, this article will also appear in the 25th edition of our quarterly publication.