Dr Hadi Moztarzadeh, Head of Technology Trends at the Advanced Propulsion Centre UK, shares key insights for the automotive industry from the JSAE congress, including advancements in battery recycling, software-defined vehicles, and sustainable practices.

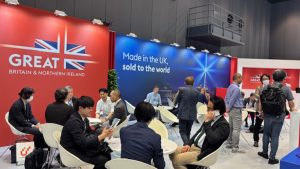

I recently had the pleasure of attending and presenting at the annual JSAE congress –hosted by the Society of Automotive Engineers Japan. As an organisation, APC has been hosting the UK Pavilion at JSAE for the past 12 years, and it has always been one of the key events in our annual calendar.

JSAE is teeming with insightful keynotes and offers a global perspective on the automotive industry, both in terms of the current state-of-play and what lies on the path ahead. It is even more important for the UK automotive industry since we have presence from two global OEMs in the UK: Nissan and Toyota.

The exhibition space was absolutely amazing, spanning two big halls with organisations and companies from all over the world represented, including major automakers and a hall jam-packed with every element and part of the supply chain that you can think of for motors, chips, hydrogen storage tanks, fuel cells, batteries, steering -you name it, it was there!

APC at JSAE

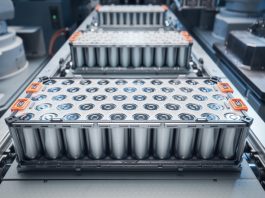

I noted how much interest there was from our international peers in what we are developing here in the UK, and I was honoured to be invited to present on behalf of APC for the first time at the event. My focus was on the UK and European battery recycling outlook, with a particular lean towards opportunities within the UK for battery recycling for lithium; how we are innovating to ensure we comply with European battery regulation requirements, which require a certain amount of the battery contents to be recycled into new cells. This threshold will increase as we move through the next decade.

Software-defined vehicles

As a takeaway from the event, I felt there were some key themes highlighted across the board, which featured in all the talks I attended. One was software-defined vehicles (SDVs) and control systems, and the application of all those technologies for every part of the vehicle itself, including how it touches all areas of the supply chain, sub-systems, and connectivity between the vehicle and infrastructure. This was all over the agenda, including the role of artificial intelligence (AI) – whether it’s for enhancing vehicle performance, providing personalised driving experiences, or maintenance of the vehicle itself, to the broader ecosystem and connectivity between the vehicle, infrastructure and urban facilities, including traffic management, charging management, and refuelling.

It was interesting to hear about a collaboration between Honda and Sony around the electric vehicle (EV) supply chain to develop a fully digital, real-time data supply with complete integration into the vehicle. Another that piqued my interest was Foxconn, a Taiwanese electronics contract manufacturer making mobile phones and tablets. They are exploring opportunities and collaborating with the likes of Nissan and JTEKTJ, a Taiwanese tier-one automotive supplier, around modular EV platforms and integrated software.

We have recently looked at the UK opportunities in automotive software and control systems, and from what I have observed, there is more to be done in this space. SDV is an area where innovation is happening at pace, and definitely something to watch closely!

Recycling, sustainability, and circular economy

Toyota Motor Europe (TME) showcased the establishment of the Toyota Circular Factory (TCF) at the JSAE congress. The first TCF will be at Toyota Manufacturing UK’s Burnaston plant in Derbyshire and will provide careful and systematic processing of vehicles at the end of their life to maximise the environmental benefits of recycling, repurposing, and remanufacturing.

It was great to learn at the event that the UK is seen as a world-leader in thinking holistically about battery recycling and sustainability. We are driven by requirements from the EU battery regulations legislation, and there is much encouragement in the UK for OEMs and the relevant UK battery industry to act now and integrate ways to meet regulations into future plans, for example, getting ready for battery passports. I was surprised to learn it is a topic not at the top of the agenda for Japan, mainly as they feel China has already taken a lead here. However, what was clear is that the Japanese are now beginning to invest in this area and are looking to the UK to learn more about what they can do, with a view to collaborating and building relationships to deliver life-cycle opportunities.

The green agenda for mobility of goods

A key theme throughout the event was the need for, and the work already in play in Japan on, creating a ‘green corridor,’ which essentially means low-emission ways to transport freight. There is discussion around regulation being introduced to encourage the sustainability of commercial vehicles and the movement of goods. This is an area that has been given considerable attention by APC in a report launched last autumn detailing the roadmap for the mobility of goods, so it was interesting to hear a talk at JSAE about this. We believe that addressing the way people and goods move and future trends in behaviours will affect the technology requirements in the coming years.

Manufacturing scale-up

There were numerous discussions at JSAE about manufacturing scale-up, specifically around battery technologies and innovation. Japan has seen China invest heavily, with the result being the establishment of numerous recycling, re-purposing, and re-manufacturing facilities, and it was great to hear from Toyota at the event about their commitment to a circular economy agenda, which they announced earlier this year in March. It is planned that their first factory to deliver the circular economy agenda principles will be established in the UK. There was a lot of noise about this at JSAE, and Toyota appears to be committed to making this happen. The circular economy model featured heavily on their event stand, and they received a lot of interest in it.

There was discussion focusing on the wider topic, not just about sustainable manufacturing of materials, but material processing and turning those raw materials or recycled materials into battery-grade or automotive-grade material for different systems and subsystems.

Emerging technologies

As you would expect, emerging technologies were at the heart of many sessions at the JSAE Congress. Topics like solid-state batteries and fast-charging solutions were among some of the highlighted innovative solutions. It was interesting to hear about investment in this by Toyota and BMW, and while it is not something we are seeing a lean towards in the UK market, it is a technology the APC has addressed in recent reports analysing the path battery chemistry development may take.

Another technology that was evident was hydrogen internal combustion engines (ICE). Again, not one that is leading the charge in the UK, but it is certainly a technology that is being given a spotlight in Southeast Asia, and it is seen as a viable technology to consider when addressing the decarbonisation of hard-to-abate applications like heavy-duty and off-highway. There were a lot of presentations at the event around this topic.

Road mapping the future

While the conversations were interesting and it was fascinating to see the routes different global regions are taking to become more sustainable within the clean-automotive sector and its supply chains, the congress underlined for me the importance of the role the roadmaps published by APC in 2024, on behalf of the Automotive Council UK, have in determining the UK’s future agenda.

Eight roadmaps were launched in total, six covering technologies and two focusing on the mobility of goods and people. One takeaway from JSAE is that these roadmaps really are a critical guide for keeping the industry focused on what we need to do to deliver a net-zero future in our automotive sector. All the topics that dominated conversations and presentations at JSAE feature heavily as cross-cutting themes through all the roadmaps, such as life cycle, AI, and digitalisation.

We have now taken the roadmaps one step further and are currently conducting an in-depth analysis of the innovations that are going to be the key to unlocking our sustainable future. We will, over the course of the next few months, be launching these into the public domain with a view that they will guide industry focus, strategy, policy and regulation, and investment; enabling the UK automotive industry to be a world-leader in the sustainable manufacture of clean technologies and powertrains supported by robust supply chains and a skilled workforce. We highlight focus areas and strategic priorities, where targeted collaboration between industry, government, and research institutions can accelerate commercialisation and add value to future-proof the UK automotive industry.

The first of our Innovation Reports, focusing on Electrical Energy Storage, is available to read now here. Further Innovation Reports will be published from autumn 2025 onwards.

In conclusion

SDVs, digitalisation, AI, and sustainability in the technology life cycle and manufacturing processes were the key themes that prevailed for me. It was really good to hear from our Japanese peers that they view the UK as a thought-leader in terms of holistic plans for end-to-end value chains for vehicles. It was clear we have a global reputation as great innovators, and this was demonstrated by Toyota highlighting its commitment to deliver its first-ever circular economy factory, siting it in the UK.

Visit the APC’s Knowledge Base to download a wealth of analysis and trends insights, including the Roadmaps and Innovation Reports.

About the Advanced Propulsion Centre UK

The Advanced Propulsion Centre UK (APC) collaborates with UK government, the automotive industry, and academia to facilitate driving research and investment in zero-emission vehicle manufacturing. Established in 2013 and jointly funded by the Department for Business and Trade (DBT and the automotive industry, the APC accelerates the technologies that support the transition to zero-emission vehicle manufacturing and towards a net-zero automotive supply chain in the UK.

With a proven track record, the APC has facilitated funding for 354 low-carbon and zero-emission projects involving 614 partners. Working with companies of all sizes, this funding since 2013 is estimated to have helped create or safeguard over 59,000 jobs in the UK. The technologies and products are projected to save over 425 million tonnes of CO2.

The APC is committed to sustaining and enhancing the UK’s long-term automotive capabilities and investments through knowledge-sharing, collaboration, and innovation. Focus in the following three key areas – Innovation, Scale-up, and Transformation – is driving innovation and investment in a globally competitive zero-emission vehicle supply chain, and building a strong economy through the delivery of safer, smarter, more sustainable, and affordable mobility.

Innovation

Funding product and process innovation of strategic and disruptive technologies for zero-emission vehicles, including digital tools and AI-driven processes.

Scale-up

Accelerating manufacturing by catalysing investment in advanced technologies for zero-emission vehicles, scaling-up sustainable production processes.

Transformation

Driving capital investment in an internationally competitive EV supply chain and upgrading or establishing new plants, securing future zero-emission vehicle assembly in the UK.

For more information go to apcuk.co.uk or follow us @theapcuk on X and ‘Advanced Propulsion Centre UK’ on LinkedIn.

Please note, this article will also appear in the 23rd edition of our quarterly publication.