Scientists from the National University of Singapore and the French Centre for Scientific Research have synthesised a special protein mimic that can self-assemble into a pore structure for industrial water production.

These protein mimics represent an entirely new class of artificial water channels (AWC) that can be used to improve the energy efficiency of current industrial water purification methods.

When incorporated into a lipid membrane, the pores permit the selective transport of water across the membrane while rejecting salt (ions).

A paper detailing the study, ‘Nature-inspired synthetic oligourea foldamer channels allow water transport with high salt rejection,’ was published in Chem.

The limitations of current industrial water purification methods

Current methods of industrial water purification involve the use of reverse osmosis and membrane distillation technologies.

Reverse osmosis, however, is a highly energy-intensive process as high pressures are needed to pass seawater or wastewater through a series of semi-permeable membranes to remove salts and other pollutants.

In light of climate change and the growing demand for fresh water, there is an incentive to develop more energy-efficient, water-selective membranes for large-scale desalination purposes.

This invention represents an excellent contribution to these efforts. The relatively high water permeability of the pores formed by these oligourea foldamers suggests that the overall energy requirement for industrial water purification can potentially be reduced.

How does the new process work?

The structures in the new protein mimic the functions of aquaporin, allowing only water molecules to cross the membrane while salts and other pollutants are rejected.

The individual oligourea foldamers are also much smaller in size (ten amino acid residues long), making them easier to modify, synthesise, and purify than aquaporin or other AWC classes.

The foldamers are amphiphilic in nature, which means they possess different charges, allowing them to assemble into more complex structures for industrial water purification. This is similar to how magnets clump together into a ball when they are in close proximity to each other.

The resulting complex, or quaternary, structures contain pore-like water channels, which are further stabilised by strong bonds known as hydrophobic and electrostatic interactions.

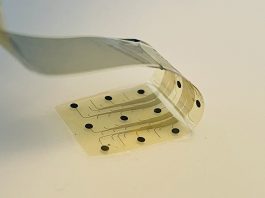

The hydrophobic components are clustered on the exterior, allowing insertion into lipid membranes, which helps industrial water purification through molecules moving across the membrane while rejecting ions from passing through.

What makes the process unique?

The development of the oligourea foldamers marks the first published attempt to create AWCs for industrial water purification.

It uses short molecular chains that can self-assemble into precise nanostructures with high porosity and selectivity for water molecules.

Professor Prakash Kumar, who led the study, explained: “The discovery of this new class of artificial water channels is significant because the individual foldamer molecules do not contain any pores, unlike other AWCs where the pores are found within their larger molecular structure.

“In our novel design, the water-selective pores only emerge when the individual units self-assemble. The high-water permeability and resistance to proteolytic degradation make these foldamers excellent candidates for industrial water purification applications.”

For the next research phase, the team plans to optimise the production of the foldamers and apply them to a larger membrane before trialling their efficiency in an industrial water purification facility.